+86 13816508465

Pump Knowledge

Oct. 22, 2025

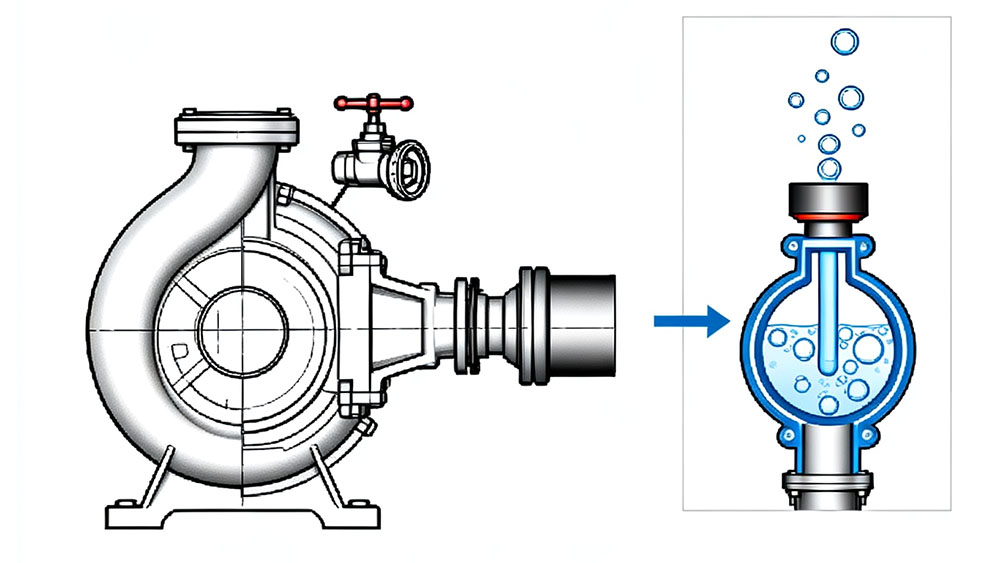

A centrifugal pump relies on a simple principle: an impeller spins to create pressure and move liquid. For this to work, the pump's internal chambers must be completely full of that liquid. However, a common and often overlooked issue is the presence of trapped air in the pump casing or suction line. This seemingly minor detail can lead to major operational failures. Venting this air before a centrifugal pump startup is not just a best practice; it is a critical step to ensure smooth operation, prevent pump cavitation, and protect the motor from serious damage.

This article will explain why air accumulates in pump systems, the damaging effects it has on performance, and the correct procedures for venting. By understanding these fundamentals, you can implement effective pump maintenance tips that extend equipment life and ensure system reliability.

Air can find its way into a hydraulic system through several common pathways. Understanding these entry points is the first step in preventing its accumulation.

One of the most frequent causes is routine maintenance. Whenever a system is opened for repairs, installation, or fluid refills, air inevitably enters the piping and pump casing. Unless it is properly removed, this air will be trapped inside when the system is sealed again.

Leaks are another significant source of air intrusion. Even a small leak in the suction-side fittings, gaskets, or valve packings can allow air to be drawn into the system while the pump is running or when it is idle. These leaks are often hard to detect because they draw air in rather than letting liquid out.

Finally, the physical layout of the piping can create natural traps for air. High points in the suction line, where the pipe rises and then falls, act as collection spots for air pockets. Without a proper venting mechanism at these high points, the air becomes trapped and can be drawn into the pump during startup.

When air is present in a centrifugal pump, it disrupts the hydraulic principles the pump relies on, leading to a cascade of negative effects.

Loss of Prime and Dry Running

A pump that contains a significant amount of air cannot build the necessary pressure differential to move liquid. The impeller spins in the air pocket without doing any real work, a condition known as 【air-bound】 or 【loss of prime.】 This forces the pump to run dry, meaning it operates without the fluid it was designed to handle. Since the pumped fluid also acts as a lubricant and coolant for the internal components, dry running quickly leads to overheating and severe mechanical wear.

Cavitation and Component Damage

Air bubbles that are drawn into the pump with the liquid are a primary cause of cavitation. As these bubbles move from the low-pressure suction side to the high-pressure discharge side of the impeller, they collapse with incredible force. These implosions generate shockwaves that hammer the impeller vanes and pump casing, chipping away at the metal surfaces. This process, known as cavitation erosion, can destroy an impeller in a surprisingly short amount of time.

Vibration and Noise

A properly functioning pump should operate smoothly and quietly. The presence of air disrupts the stable flow of liquid through the pump, creating an erratic, pulsating discharge. This hydraulic instability results in significant vibration and noise. The rattling or grinding sounds are a clear auditory signal that air is compromising your system. Chronic vibration can loosen fittings, damage bearings, and weaken pipe supports over time.

Reduced Efficiency

Air in the system dramatically reduces a pump's hydraulic performance. It cannot move its rated volume of fluid or achieve its designed pressure, leading to inefficient operation. To compensate for this performance loss, the motor may draw more power, increasing energy consumption and operational costs without delivering the desired output.

Ignoring the need for venting air in pumps before a centrifugal pump startup can lead to immediate and long-term consequences.

Overheating: Without fluid to dissipate heat, the pump’s mechanical seals and bearings can fail within minutes due to excessive friction from dry running.

Mechanical Damage: The violent forces of cavitation and excessive vibration can cause catastrophic failure, leading to cracked casings, broken impellers, and damaged shafts.

Operational Delays: A pump that fails to build pressure will not perform its function, causing costly delays in production or facility operations.

Shortened Lifespan: Even if the pump does not fail immediately, repeated operation with trapped air will cause cumulative damage, significantly reducing its service life and increasing maintenance frequency.

Venting is a straightforward procedure that should be part of every pre-startup checklist.

1. Open the Vent: Locate the air vent plug or valve on the highest point of the pump casing (volute). Slowly open it to allow trapped air to escape. You will hear a hissing sound as air is released.

2. Wait for Solid Liquid Flow: Keep the vent open until all the air has been expelled and a steady, bubble-free stream of liquid flows out. Once this occurs, securely close the vent plug or valve.

3. Inspect the Suction Line: Ensure the suction piping slopes continuously upward toward the pump to prevent air pockets from forming. Check all fittings for tightness.

4. Use Automatic Valves: For large systems or applications where the pump starts and stops frequently, consider installing automatic air release valves at high points in the piping to automate the venting process.

Proactive prevention is a core component of effective pump maintenance tips.

Always use high-quality gaskets and ensure all suction-side flanges and fittings are properly tightened to maintain an airtight seal.

Design suction piping to eliminate high spots where air can collect. If a high point is unavoidable, install a manual or automatic air vent valve there.

Ensure that the suction valve is fully open before starting the pump to avoid creating a vacuum that can pull air through minor leaks.

Periodically inspect vent valves and plugs to ensure they are not clogged with debris, which would prevent them from functioning correctly.

Knowing when to vent is as important as knowing how. This procedure should be performed:

After any new installation or after the system has been opened for maintenance.

Before every startup if the pump has been idle for an extended period, as air may have slowly leaked into the system.

Whenever you notice performance issues like unusual noise, excessive vibration, or a failure to reach operating pressure.

Venting air before a centrifugal pump startup is a simple, quick, and essential task that protects your investment and ensures system reliability. This small step eliminates the immediate risks of dry running and the destructive long-term effects of cavitation. By incorporating proper venting into your standard operating procedures and following good pump maintenance tips, you ensure efficient operation, extend equipment life, and prevent costly, unexpected downtime. A well-vented pump is a reliable pump.

Address

No.17 XeDa Jimei Ind. Park, Xiqing Economic Development Area, Tianjin, China

Telephone

+86 13816508465

QUICK LINKS