+86 13816508465

Pump Knowledge

Oct. 22, 2025

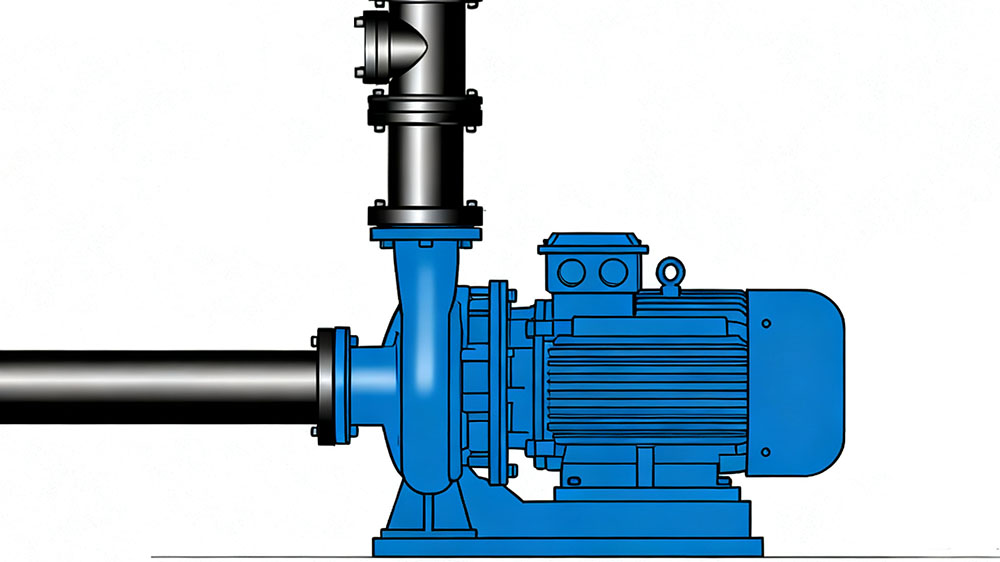

A centrifugal pump is the engine of a fluid transfer system, but its performance is only as good as the piping connected to it. The layout of the suction and discharge lines is not a minor detail—it directly determines pump efficiency, reliability, and service life. A poorly designed piping system can lead to chronic issues like cavitation, excessive vibration, and premature mechanical seal failure, resulting in costly downtime and repairs.

Understanding and implementing correct piping practices is one of the most effective ways to ensure a healthy, long-lasting pump system. This guide will walk you through the essential best practices for suction and discharge piping design, highlight common mistakes, and provide practical tips to optimize your centrifugal pump’s performance from day one.

At a basic level, the function of pump piping seems simple. However, the details of how it's designed are what separate a reliable system from a problematic one.

Suction Line Function: The primary job of the suction line is to deliver a smooth, stable stream of fluid to the pump's inlet. It must do this with minimal turbulence and pressure loss to ensure the pump receives enough fluid to operate correctly. A well-designed suction line is the first line of defense in preventing cavitation.

Discharge Line Function: The discharge line's role is to guide the pressurized fluid from the pump's outlet to its final destination. It must manage the flow and pressure effectively while minimizing energy loss. Proper discharge piping layout ensures the pump operates at its best efficiency point and isn't subjected to excessive backpressure or hydraulic shock.

The guiding principle for both is to create a piping system that is independently supported and promotes a stable, laminar flow, preventing unnecessary stress on the pump itself.

The suction side is the most critical part of any pump piping system. More than 80% of centrifugal pump problems originate here. Getting the suction piping design right is essential for maximizing centrifugal pump efficiency and longevity.

1. Pipe Diameter and Length

Always use a suction pipe with a diameter equal to or, preferably, one size larger than the pump's suction inlet. An oversized suction line reduces the fluid velocity and minimizes friction losses, which helps improve the Net Positive Suction Head Available (NPSHa).

Keep the suction piping as short and straight as possible. Every bend, valve, and foot of pipe adds to friction loss, which reduces the pressure at the pump's inlet and increases the risk of cavitation.

2. The Importance of a Straight Run

To ensure a smooth, non-turbulent flow enters the pump impeller, provide a straight run of pipe directly before the suction nozzle. A common rule of thumb is to have a straight length that is at least 5 to 10 times the pipe's diameter. This straight section allows any turbulence from upstream components like elbows or valves to settle down, preventing uneven loading on the impeller.

3. Avoiding Air Pockets

Air is the enemy of a centrifugal pump. Trapped air can lead to a loss of prime, reduced performance, and cavitation. To prevent air pockets in horizontal suction lines, always use eccentric reducers with the flat side on top. This design eliminates the high point where air can accumulate, which would otherwise occur with a concentric reducer.

Elbows mounted directly on the suction flange should also be avoided. An elbow creates a swirling flow that can unbalance the impeller. If an elbow is necessary, it should be a long-radius type and installed with a straight run of pipe between it and the pump.

4. Suction Lift vs. Flooded Suction

A flooded suction—where the fluid source is located above the pump's centerline—is always the preferred arrangement. This setup ensures the pump is constantly primed and provides a positive pressure head at the inlet, maximizing NPSHa.

In suction lift applications, where the pump must draw fluid from a source below it, extra care is needed. These systems often require a foot valve at the end of the suction line to maintain prime and must be carefully designed to ensure the pump can lift the fluid without cavitating.

While not as sensitive as the suction side, the discharge piping layout is crucial for controlling flow, managing pressure, and protecting the pump from system upsets.

1. Gradual Expansion

If the discharge pipe is larger than the pump's outlet nozzle, use a gradual conical expander (diffuser) rather than an abrupt change in diameter. This gradual expansion minimizes turbulence and converts velocity back into pressure energy more efficiently, reducing overall energy consumption.

2. Correct Valve Placement

Every discharge line should include two key valves: a check valve and an isolation valve.

Check Valve: This valve prevents backflow when the pump is shut down, protecting it from reverse rotation and water hammer.

Isolation Valve (Gate or Ball Valve): This valve allows maintenance crews to isolate the pump from the rest of the system for service.

The correct sequence is to install the check valve first, followed by the isolation valve. Both should be placed at least 5 pipe diameters away from the pump outlet to prevent them from creating turbulence that could affect the pump's performance.

3. Instrumentation for Monitoring

Install pressure gauges near both the suction and discharge flanges. These instruments are invaluable for diagnosing pump performance issues, monitoring system health, and determining if the pump is operating near its Best Efficiency Point (BEP). Flow meters can also be installed in the discharge line for precise system control and diagnostics.

4. Accommodating Movement

In systems with temperature variations, pipes will expand and contract. Use expansion joints or flexible connectors in the discharge line to absorb this movement and prevent it from creating pipe strain on the pump casing. These connectors also help dampen vibration transmission between the pump and the piping system.

Many pump failures can be traced back to a few common and easily preventable piping mistakes. Be sure to avoid these pitfalls:

Forcing Pipes to Fit: Never use flange bolts to pull misaligned pipes into place. This creates severe pipe strain, which distorts the pump casing and leads to misalignment and seal failure.

Undersized Suction Lines: This increases fluid velocity, creates high friction losses, and is a leading cause of cavitation.

Using Concentric Reducers Horizontally: Placing a concentric reducer on a horizontal suction line creates a perfect trap for air at the top of the pipe.

Placing Valves or Elbows Too Close: Any component that creates turbulence should be kept far away from the pump's inlet.

Using the Pump as an Anchor: The pump is not a pipe support. All piping must be independently supported to prevent its weight from being transferred to the pump casing.

A good design is only effective if it's installed correctly. Follow these best practices during installation:

1. Support All Piping Independently: Use appropriately spaced pipe hangers and supports to ensure the piping system bears its own weight.

2. Align the Pump First: Complete the pump and motor alignment before connecting any piping.

3. Recheck Alignment After Connecting: Once the piping is bolted on, re-verify the shaft alignment. If it has changed, there is pipe strain that must be corrected.

4. Allow for Thermal Growth: In hot systems, design the piping with expansion loops or joints to manage thermal expansion safely.

5. Flush All Lines: Before connecting the final pipe sections to the pump, thoroughly flush the entire system to remove any dirt, weld slag, or debris left over from construction.

A well-designed piping layout is not an optional accessory; it is a fundamental part of the centrifugal pump system. Proper suction piping design and discharge piping layout are the most effective measures you can take to ensure high centrifugal pump efficiency, reliable operation, and a long service life. By minimizing turbulence, preventing cavitation, and eliminating pipe strain, you reduce maintenance costs, improve mechanical seal and bearing life, and create a more robust and dependable system.

Before starting your next installation, remember this: the time invested in planning and executing the piping correctly will pay for itself many times over in reduced downtime and lower operational costs.

Address

No.17 XeDa Jimei Ind. Park, Xiqing Economic Development Area, Tianjin, China

Telephone

+86 13816508465

QUICK LINKS