+86 13816508465

Pump Knowledge

Oct. 22, 2025

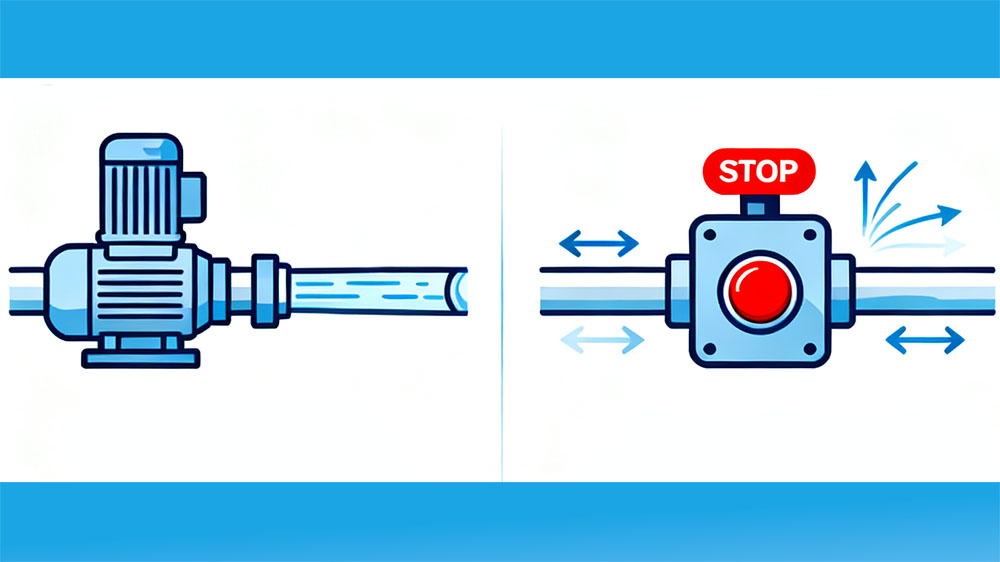

A sudden, loud thud reverberating through your pipeline can mean thousands of dollars in damage. That's water hammer, a destructive hydraulic phenomenon that often begins when pumps are switched on or off incorrectly. Understanding and preventing it is crucial for the safety and longevity of any fluid handling system.

Water hammer, or hydraulic shock, is a high-pressure surge created by a sudden change in the speed of a liquid moving through a pipe. It is most common during rapid pump startups and shutdowns. This article explains the causes, consequences, and proven solutions for preventing water hammer, including gradual valve operation, modern motor controls, and specialized surge protection devices.

Understanding Water Hammer

At its core, water hammer is a physics problem. When a column of moving fluid is forced to stop or change direction abruptly, its kinetic energy is instantly converted into pressure energy. Since liquids are nearly incompressible, this energy has nowhere to go and creates a powerful pressure wave that travels through the pipe at high speed.

This shockwave is what causes the characteristic 【hammering】sound. Other common symptoms include violent pipe vibration, sudden pressure spikes on gauges, and even visible movement of the pipeline itself. The effect is most pronounced in long pipelines or high-pressure systems where the moving fluid has significant momentum.

Why It Happens During Pump Startup and Shutdown

Pump operations are the most common trigger for water hammer. Both starting and stopping a pump can introduce the sudden velocity changes that create hydraulic shock.

Startup-Related Causes:

Rapid Acceleration: Starting a pump with the discharge valve wide open forces the entire column of liquid in the pipeline to accelerate from zero to full speed almost instantly. This sudden push creates a high-pressure wave.

Lack of Soft Start: A motor that starts instantly (direct-on-line) imparts maximum torque to the pump, causing an immediate high-velocity flow that shocks the system.

Shutdown-Related Causes:

Sudden Stop: An abrupt pump stop, often due to a power failure or an emergency stop, causes the forward-moving column of liquid to halt suddenly. The momentum can cause the liquid column to separate and then slam back together, creating a massive pressure surge.

Check Valve Slam: When the pump stops, flow reversal can occur. If a standard swing check valve is used, the reverse flow can slam the valve disc shut, creating an instantaneous blockage that generates a severe pressure wave upstream.

The Damaging Consequences of Water Hammer

The force generated by a water hammer event can be immense, leading to a range of costly and dangerous failures.

Burst Pipes and Cracked Fittings: The pressure spike can exceed the pressure rating of pipes and fittings, causing catastrophic ruptures.

Damaged Pump Components: The shockwave can travel back into the pump, damaging mechanical seals, bearings, and even fracturing the impeller or casing.

System Leaks: Flanges and joints can be forced apart by the pressure surge, leading to persistent leaks and fluid loss.

Damaged Instrumentation: Delicate pressure gauges, sensors, and transmitters can be destroyed by the sudden overpressure.

Costly Downtime: Repairing a system damaged by water hammer leads to significant operational downtime and expensive replacement costs.

Preventing water hammer starts with controlling the acceleration of the fluid. Following a proper startup procedure is the most effective method.

1. Start with the Discharge Valve Closed: The most important step is to start the centrifugal pump against a closed discharge valve. This allows the pump to build pressure without creating flow in the main pipeline.

2. Use Soft Starters or VFDs: Employ a soft starter or a variable frequency drive (VFD) to ramp up the motor speed gradually. This ensures the pump accelerates smoothly, preventing a sudden jolt to the system.

3. Check for Trapped Air: Before startup, ensure the system is fully primed and that all air has been vented from high points. Air pockets can compress and decompress, amplifying pressure surges.

4. Slowly Open the Discharge Valve: Once the pump is running at full speed against the closed valve, open the discharge valve very slowly. This allows the flow in the pipeline to accelerate gradually, preventing the formation of a pressure wave.

5. Monitor System Pressure: As you open the valve, watch the pressure gauges. A smooth, controlled rise in pressure indicates a safe startup. A sudden spike is a sign that the valve is being opened too quickly.

Just as with startup, a controlled shutdown is essential to prevent water hammer caused by rapid deceleration.

1. Slowly Close the Discharge Valve: Before stopping the motor, gradually close the discharge valve. This brings the flow in the pipeline to a controlled stop, safely dissipating the fluid's kinetic energy.

2. Stop the Motor: Once the discharge valve is fully closed and flow has ceased, the pump motor can be safely turned off.

3. Use Controlled Deceleration: If using a VFD, program a soft-stop or ramp-down sequence to gradually decrease the pump's speed before it stops completely.

4. Install a Non-Slam Check Valve: Replace standard swing check valves with 【non-slam】 or 【silent】 check valves. These valves are designed to close quickly but gently just before flow reversal occurs, preventing the slam that generates water hammer.

5. Consider System Design: In systems with high static head or long pipelines, a simple shutdown might not be enough. Protective devices may be required.

For systems prone to severe water hammer, incorporating specific design elements and equipment can provide an extra layer of protection.

Surge Arrestors or Accumulators: These devices are hydraulic shock absorbers. They use a bladder or piston backed by pressurized gas (like nitrogen) to absorb the pressure wave, protecting the pipeline from overpressure.

Air Release Valves: These valves are installed at high points in a pipeline to automatically vent trapped air, which can worsen water hammer effects.

Slow-Closing Control Valves: Automated valves can be programmed to open and close over a specific time, ensuring a smooth transition during every cycle.

Surge Tanks: In large-scale systems like municipal water lines, a surge tank (or standpipe) provides a simple way for pressure surges to dissipate by allowing the water level to rise and fall safely.

Real-World Example: Municipal Water Station

A municipal water station was experiencing repeated pipe bursts at a remote booster pump station. The problem was traced to abrupt pump stops during frequent power outages. The sudden stop caused the check valve to slam shut, creating a massive pressure surge that stressed the aging pipeline to its breaking point. The solution was two-fold: they replaced the old swing check valves with modern non-slam check valves and installed pump control panels with VFDs programmed for a controlled ramp-down upon loss of power (powered by a small UPS). The changes completely eliminated the water hammer events, preventing further pipe damage and saving the municipality thousands in emergency repair costs.

Always operate valves slowly. Quick actions are the primary cause of hydraulic shock.

Train all operators on correct startup and shutdown procedures for each system.

Regularly inspect check valves to ensure they are functioning correctly and not sticking.

Use pressure monitoring systems with alarms to detect and record any surge events.

Follow manufacturer recommendations for pump and motor acceleration and deceleration rates.

Water hammer is one of the most damaging hydraulic events in a pump system, but it is also one of the most preventable. The key is control. By using smooth valve control, soft starters, and proper system design, you can eliminate dangerous pressure surges. Adhering to correct startup and shutdown procedures ensures quiet, reliable operation and protects your valuable equipment from the destructive force of hydraulic shock.

Address

No.17 XeDa Jimei Ind. Park, Xiqing Economic Development Area, Tianjin, China

Telephone

+86 13816508465

QUICK LINKS