+86 13816508465

Oct. 20, 2025

It only takes one wrong step—starting your centrifugal pump with the suction valve closed—to cause seal failure, overheating, or even motor burnout in a matter of minutes. This seemingly small oversight is one of the most destructive mistakes an operator can make, leading to costly downtime and equipment damage. Understanding why this happens is key to ensuring safe, reliable, and efficient pump operation in any industrial setting.

A centrifugal pump is designed with a fundamental principle in mind: it needs a continuous, unrestricted flow of liquid into its suction port to function. Starting the pump with a closed or blocked suction valve effectively [starves] it of the fluid it needs to move. This creates a vacuum condition that triggers a cascade of destructive events, including severe cavitation, dry running, and overheating. These issues can quickly destroy critical components and lead to catastrophic failure.

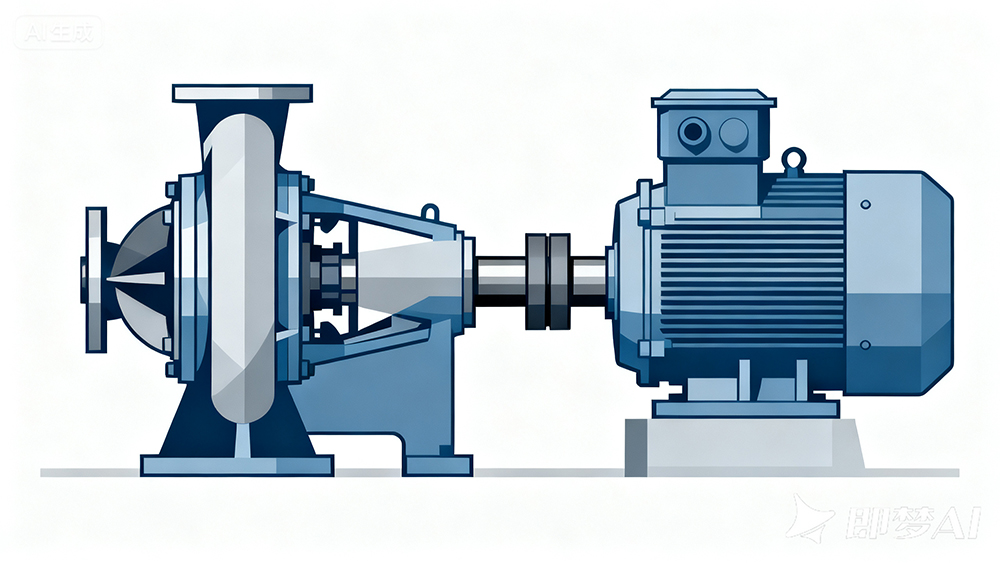

To understand the danger, it's helpful to review the basic operation of a centrifugal pump. The pump uses a rotating impeller to draw liquid into its center (the eye) and throw it outward by centrifugal force. This action increases the liquid's velocity and pressure, pushing it through the discharge port and into the piping system.

This entire process depends on a positive and steady supply of liquid at the suction inlet. The rotation of the impeller creates a low-pressure zone at the eye, which pulls more fluid in. If the suction valve is closed, there is no liquid to draw from. Instead of a stable flow, the pump creates a strong vacuum, and any trapped liquid or air pockets inside the casing are subjected to extreme pressure changes.

Starting a pump without suction flow initiates a rapid sequence of damaging events. The consequences are not just mechanical but also thermal and electrical, affecting the entire pump assembly.

1. Immediate, Severe Cavitation: When the impeller spins in a vacuum, the low pressure causes the small amount of trapped liquid inside the casing to flash into vapor bubbles. As these bubbles move from the low-pressure eye to the high-pressure edge of the impeller, they collapse violently. This implosion generates intense shockwaves, acting like tiny hammer blows against the impeller and pump casing. This phenomenon, known as cavitation, can erode metal surfaces, causing pitting and irreversible damage in seconds.

2. Dry Running and Seal Failure: The liquid flowing through a pump does more than just get moved—it also lubricates and cools critical components, especially the mechanical seal. Without a steady flow, the seal faces run dry. The friction generates immense heat almost instantly, burning, cracking, or shattering the delicate seal faces. A failed seal results in significant leakage and requires a complete pump overhaul to repair.

3. Overheating: Beyond the seal, the entire pump begins to overheat. The energy from the spinning motor has nowhere to go, as there is no fluid to absorb and carry away the heat. This can damage bearings, warp the casing, and cause impeller-to-casing contact.

4. Excessive Vibration and Noise: A pump running without liquid is an unbalanced system. The violent collapse of vapor bubbles during cavitation and the erratic movement of trapped air create significant vibration and a loud noise often described as [pumping rocks.] This vibration can damage bearings, couplings, and the motor itself.

5. Potential Motor Overload: While a closed discharge valve leads to a low power draw, a closed suction valve can cause erratic load conditions. The pump may struggle to build pressure, causing fluctuations in motor current that can lead to overload trips or, in worst-case scenarios, damage to the motor windings.

Following a proper startup sequence is the best way to prevent these issues. This checklist highlights the correct valve positions and checks to perform before energizing the motor.

1. Ensure the Pump is Primed: First, verify that the suction line and pump casing are completely full of liquid. All air must be bled from the system. A pump that isn't fully primed will behave similarly to one with a closed suction valve.

2. Confirm Suction Valve is Fully Open: This is the most critical step. Physically check that the suction isolation valve is 100% open and that there are no obstructions in the suction line.

3. Set the Discharge Valve: Close or partially close the discharge valve. Starting against a closed discharge valve is a best practice for centrifugal pumps, as it minimizes the initial load on the motor.

4. Perform Final Checks: Ensure all guards are in place, ancillary systems (like seal flush plans) are active, and the area is clear of personnel.

5. Start the Pump Motor: Energize the motor. Listen for any unusual noises and watch for excessive vibration.

6. Monitor Pressure and Current: The discharge pressure gauge should immediately rise to the pump's shut-off head. The motor's amperage draw should be at its lowest point.

7. Gradually Open the Discharge Valve: Slowly open the discharge valve until you reach the desired flow rate and operating pressure. As you open the valve, the motor current will gradually increase to its normal operating level.

8. Final System Check: Once the pump is at its duty point, confirm that all parameters—pressure, current, and noise levels—are stable and within the expected range.

Consider a scenario at a chemical processing plant. During a hasty midnight shift change, an operator was tasked with starting a backup water pump. Rushing through the procedure, the operator failed to verify that the suction valve, which had been closed for maintenance, was open. He pressed the start button and walked away.

Within two minutes, the pump began to vibrate violently. The mechanical seal, running completely dry, superheated and shattered. The extreme heat from the friction and cavitation caused the impeller to seize against the casing. The motor, struggling against the locked rotor, overloaded and tripped its breaker. The result was a destroyed pump, a flooded floor from the failed seal, and hours of costly, unplanned downtime. All of this could have been avoided by simply checking one valve.

To build reliability into your operations and prevent catastrophic failures, implement these safety measures:

Lockout/Tagout Procedures: Incorporate valve position checks into your standard lockout/tagout (LOTO) procedures for pump maintenance.

Use Suction Pressure Gauges: Install a pressure or vacuum gauge on the suction side of the pump. A gauge showing a strong vacuum upon startup is an immediate indicator of a blocked suction line.

Install Dry-Run Protection: Modern pumps can be fitted with sensors that detect low flow, high temperature, or power fluctuations indicative of dry running. These sensors can automatically shut down the pump before major damage occurs.

Operator Training: Regular and thorough training is the best defense. Ensure all operators understand not just the [how] but the [why] behind every step in the startup sequence.

Clear Labeling: Clearly label all valves in the system (e.g., P-101 SUCTION - NORMALLY OPEN) to reduce human error.

A centrifugal pump is designed to move liquid, not air. Starting it with a closed suction valve starves the pump, guaranteeing rapid and severe damage from cavitation, overheating, and dry running. Always verify that the suction valve is fully open and the pump is primed before startup to ensure safe, efficient, and reliable operation. This simple check protects your equipment, prevents costly downtime, and maintains a safer work environment.

Address

No.17 XeDa Jimei Ind. Park, Xiqing Economic Development Area, Tianjin, China

Telephone

+86 13816508465

QUICK LINKS