+86 13816508465

Pump Knowledge

Nov. 20, 2025

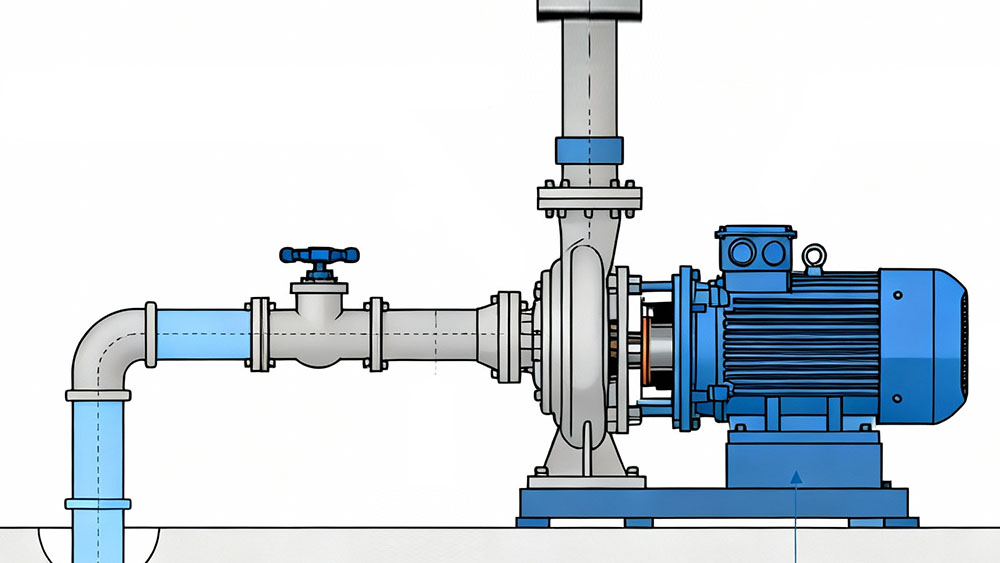

Choosing the right pump for a specific application seems straightforward, but a common mismatch can lead to significant operational issues. One such mistake is using a high-head pump for a low-head application. This choice often stems from a misunderstanding of how pumps operate, leading to unexpected consequences for both performance and electrical consumption.

This article will analyze how using a high-head pump in a low-head system impacts the pump's electrical current draw. We will explore the technical relationship between pump head and flow, the resulting risks of motor overload, and the best practices for selecting the right equipment. Understanding these principles is key to ensuring system efficiency, reliability, and safety.

To grasp the problem, we first need to understand the fundamental concepts of pump head and flow. [Head] refers to the height to which a pump can lift fluid, which translates to the pressure it can generate. [Flow] is the volume of fluid the pump can move in a given time. These two parameters are inversely related, a relationship visualized in a pump's performance curve.

The Pump Curve: A Visual Guide

Every centrifugal pump has a unique performance curve that shows the relationship between the head it produces and the flow rate it delivers. Generally, as the flow rate increases, the head decreases. A pump operates most efficiently at its Best Efficiency Point (BEP), which is the ideal combination of head and flow for its design.

A high-head pump is designed to generate high pressure. This is often achieved with multiple impeller stages, tighter internal clearances, and a design optimized for pushing fluid against significant resistance. Its BEP is located at a high-head, relatively low-flow point on its curve.

When you install this pump in a low-head system, the resistance is much lower than what it was designed for. According to its curve, lower resistance (head) allows the pump to move a much larger volume of fluid. This forces the pump to operate far to the right of its BEP, in a high-flow, low-head region where it is inefficient and unstable.

Operating a pump away from its BEP has direct electrical consequences. The amount of power a pump consumes is directly related to the work it performs—moving a certain volume of fluid against a certain pressure.

Increased Flow and Power Draw

When a high-head pump operates in a low-head system, the dramatically increased flow rate forces the motor to work harder. Moving more fluid volume requires more torque from the motor. To provide this higher torque, the motor must draw more electrical current from the power supply.

This phenomenon is a common point of confusion. Many assume that because the pump isn't working against high pressure, it will use less power. However, for centrifugal pumps, the hydraulic load is a function of both head and flow. In this scenario, the massive increase in flow outweighs the reduction in head, leading to a net increase in power consumption and current draw.

Motor Overload Risks

Every electric motor has a rated full-load amperage (FLA), which is the maximum current it can safely draw continuously without overheating. When a pump forces its motor to draw a current exceeding this rating, it enters an overload condition.

For example, reducing the operating head of a high-head pump by just 30-40% can cause the current draw to surge well beyond the motor's FLA. If this condition persists, the motor's windings will generate excessive heat. This heat degrades the insulation, drastically reduces the motor's lifespan, and can lead to premature failure. In many cases, the motor's overload protection will trip, shutting down the system to prevent catastrophic damage.

The problems are not just electrical. Operating a high-head pump in a low-head environment creates significant hydraulic and mechanical stress, leading to a cascade of issues.

Cavitation and Instability

Operating far to the right of the BEP increases the risk of cavitation. Cavitation occurs when the pressure within the pump drops below the liquid's vapor pressure, causing tiny vapor bubbles to form. These bubbles collapse violently as they move into higher-pressure zones, creating shockwaves that erode the impeller and pump casing.

This unstable hydraulic condition also causes significant vibration and noise. The excessive forces place immense strain on the pump's mechanical components. Bearings and mechanical seals, which are designed for the stable conditions near the BEP, experience increased wear and are prone to early failure. The result is a less efficient, noisy, and unreliable system that requires frequent maintenance.

Consider a common scenario: an industrial facility needs to transfer water for a cooling process that requires only 10 meters of head. A maintenance team, having a spare high-head pump rated for 50 meters, decides to install it to save on procurement costs.

Initially, the pump seems to work—it moves water. However, problems soon appear. The flow rate is much higher than needed, causing issues downstream. More importantly, maintenance technicians notice the motor is running unusually hot. A clamp meter reveals the current draw is 25% above the motor's FLA rating.

Within weeks, the motor's thermal overload protection starts tripping regularly, causing system downtime. If left unaddressed, the motor would eventually fail completely. The attempt to save money by using an existing pump ends up costing more in downtime, repairs, and ultimately, the need to purchase the correct pump anyway.

Avoiding these issues comes down to proper pump selection and system design. Following these best practices will ensure long-term reliability and energy efficiency.

1. Match the Pump to the System: Always start by accurately calculating your system's total dynamic head and required flow rate. Select a pump whose BEP is as close as possible to these operating conditions.

2. Use the Pump Curve: Never select a pump without consulting its performance curve. Verify that your system's design point falls within the pump's recommended operating range.

3. Control the System, Not the Pump: If your system conditions vary, consider using a variable frequency drive (VFD). A VFD adjusts the motor's speed to match the required head and flow, keeping the pump operating efficiently and preventing motor overload. Throttling the discharge with a valve can also increase head and reduce flow, but this is less energy-efficient than using a VFD.

4. Consult with Experts: When in doubt, consult the pump manufacturer's data sheets or work with a qualified engineer. Using simulation tools can also help predict how a pump will perform in your specific system.

Using a high-head pump for a low-head application is a costly mistake. While it may seem like a convenient shortcut, it forces the pump to operate in an inefficient and damaging high-flow condition. This leads directly to increased electrical current draw, motor overload, and a high risk of mechanical failure from vibration and cavitation.

The key takeaway is simple: proper pump selection is critical. By taking the time to calculate system requirements and carefully matching them to the pump's performance curve, you can ensure your system runs efficiently, reliably, and safely for years to come. This foundational step saves energy, reduces maintenance costs, and prevents the unexpected downtime caused by a simple mismatch.

Address

No.17 XeDa Jimei Ind. Park, Xiqing Economic Development Area, Tianjin, China

Telephone

+86 13816508465

QUICK LINKS