+86 13816508465

Pump Knowledge

Oct. 21, 2025

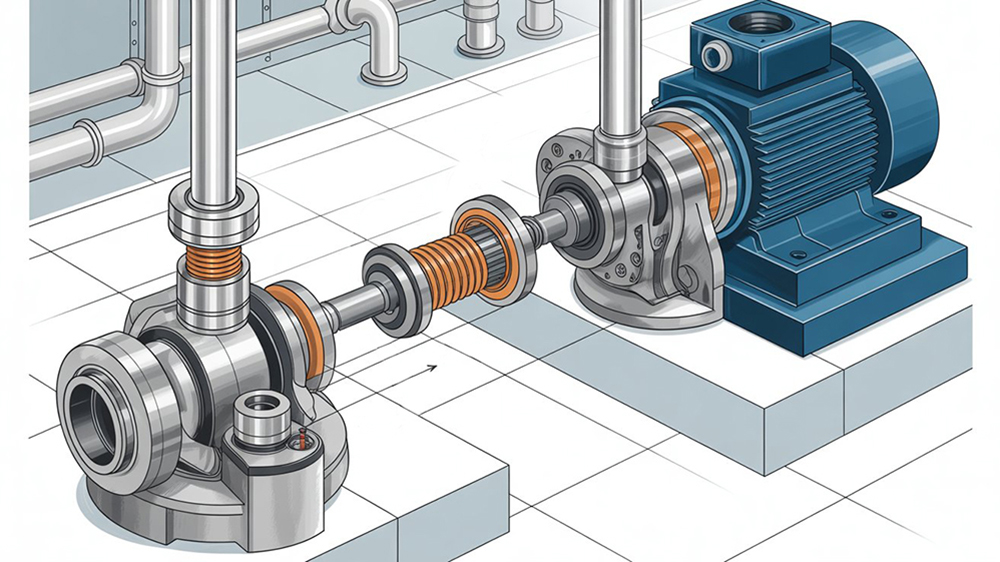

A centrifugal pump is the heart of many industrial fluid systems, and its reliability is paramount. While components like the motor and impeller get a lot of attention, the small but mighty flexible coupling is just as critical. Proper flexible couplings installation is not just a maintenance task; it's a foundational step that ensures the long-term health and efficiency of your entire pump system.

Incorrect installation is a common source of premature equipment failure. It can lead to severe vibration, bearing damage, and costly seal leaks. This guide provides a detailed walkthrough of the right way to install flexible couplings, helping you reduce pump vibration, extend equipment life, and improve operational reliability.

A flexible coupling is a mechanical component that connects the drive shaft of a motor to the shaft of a pump. Its primary job is to transmit rotational power efficiently. Unlike rigid couplings, flexible couplings can accommodate small amounts of shaft misalignment—angular, parallel, and axial—that naturally occur in any system. This flexibility helps absorb shock loads and dampen vibrations, protecting sensitive components like bearings and mechanical seals.

There are several types of flexible couplings, each suited for different applications:

Jaw Couplings: These feature a simple design with an elastomeric insert (the spider) that provides vibration damping and failsafe operation.

Grid Couplings: A flexible steel grid weaves between the hub teeth, allowing for high torque transmission while absorbing shock.

Gear Couplings: Designed for high-torque and high-speed applications, these consist of two hubs with external gear teeth connected by a flanged sleeve with internal teeth.

Elastomeric Couplings: These use rubber or polymer elements in compression or shear to transmit torque, offering excellent vibration isolation and misalignment tolerance.

Choosing the right coupling depends on your system's torque requirements, expected misalignment, operating environment, and centrifugal pump maintenance schedule.

Thorough preparation is the key to a successful installation. Rushing this stage often leads to mistakes that can compromise the entire setup.

Safety First

Before you begin any work, prioritize safety. Disconnect all power to the motor and follow your facility's lockout/tagout (LOTO) procedures. This crucial step prevents accidental startups and ensures a safe working environment for everyone involved.

Inspect and Clean

Unpack the new coupling and carefully inspect all its components for defects or damage that may have occurred during shipping. Verify that the bore size and keyway dimensions on the hubs match the pump and motor shafts.

Next, thoroughly clean the shaft and hub surfaces. Use a wire brush and a suitable solvent to remove any grease, rust, paint, or dust. A clean, smooth surface is essential for a secure fit and accurate alignment.

Gather Your Tools

Having the right tools on hand makes the job smoother and more precise. You will need:

Precision alignment tools (dial indicators or a laser alignment system)

A straight edge and feeler gauges for initial checks

A torque wrench for tightening fasteners correctly

Hub heating equipment (if required)

Standard hand tools (wrenches, Allen keys)

With preparation complete, you can now proceed with the installation. Follow these steps carefully to ensure a precise and secure fit.

1. Mount the Hubs

Avoid using a hammer to force a hub onto a shaft, as this can damage the bearings and other components. If the hub has an interference fit, gently heat it using an induction heater or an oven to a temperature recommended by the manufacturer (typically around 275°F or 135°C). The heat will expand the hub, allowing it to slide onto the shaft easily.

Position the hubs on their respective shafts, ensuring the gap between them matches the manufacturer's specifications. This gap, often called the 【distance between shaft ends】 (DBSE), is critical for allowing the coupling to flex properly.

2. Perform Shaft Alignment

This is the most critical step in the entire process. Precise alignment minimizes stress on the coupling, bearings, and seals. The goal is to align the pump and motor shafts both radially (parallel) and axially (angular).

Parallel Misalignment: The centerlines of the two shafts are parallel but not in the same line.

Angular Misalignment: The shafts are at an angle to each other.

Use either dial indicators or a laser alignment system to measure and correct misalignment. Adjust the motor's position by adding or removing shims under its feet until both angular and parallel alignment are within the coupling manufacturer’s specified tolerances. These tolerances are often very small—just a few thousandths of an inch.

3. Install the Flexible Element

Once the shafts are aligned, install the flexible element between the hubs. The method will vary depending on the coupling type (e.g., inserting a spider, wrapping a grid, or bolting sleeves together). Follow the manufacturer’s instructions closely.

When securing any fasteners, tighten them gradually in a crisscross pattern to ensure even pressure. Use a torque wrench to apply the correct torque value specified in the installation manual. Over-tightening or under-tightening bolts can lead to premature failure.

4. Verify Alignment Again

After all bolts are tightened, it's essential to recheck the alignment. The process of tightening fasteners can sometimes cause slight shifts in the motor's position. Verifying the alignment one last time ensures the final assembly is as precise as possible.

5. Perform a Rotation Test

Before reinstalling the coupling guard, manually rotate the shafts by hand for several full revolutions. The rotation should feel smooth and free of any binding or interference. This simple test confirms that all components are correctly installed and move freely.

Many pump failures can be traced back to simple installation errors. Here are some common mistakes that can drastically reduce the life of your pump and coupling:

Forcing hubs with a hammer: This can cause brinelling (indentations) in the bearings and damage the shafts.

Ignoring alignment tolerances: Relying on the 【flexibility】 of the coupling to compensate for poor alignment is a recipe for disaster. This overloads the coupling and transfers stress to the pump and motor.

Guessing bolt torque: Improperly tightened fasteners can lead to fretting corrosion or catastrophic failure if they come loose during operation.

Failing to account for thermal growth: In hot-running applications, machinery can expand as it reaches operating temperature. It is good practice to perform alignment checks under both cold and hot conditions.

Your work isn't done once the pump is running. Proper post-installation checks and ongoing centrifugal pump maintenance are vital for long-term reliability.

During the initial run, listen for any unusual noises and monitor for excessive vibration or high temperatures around the bearings and coupling. After a few hours of operation, consider shutting down the system to recheck alignment, as components may settle or shift due to thermal expansion.

Regular maintenance should include:

Lubrication: For grid or gear couplings, follow the recommended lubrication schedule.

Visual Inspection: Regularly inspect the flexible element for signs of wear, cracking, or degradation.

Safety: Always ensure the coupling guard is securely in place to prevent injury.

Proper flexible couplings installation is a blend of precision, patience, and adherence to best practices. By taking the time to prepare correctly, align the shafts accurately, and follow manufacturer guidelines, you can significantly reduce pump vibration and prevent premature failures. A well-installed coupling ensures smooth power transmission, protects your equipment, and contributes to a more reliable and efficient operation.

Investing in proper pump alignment tips and installation techniques pays dividends in the form of longer equipment life, reduced downtime, and lower maintenance costs.

Address

No.17 XeDa Jimei Ind. Park, Xiqing Economic Development Area, Tianjin, China

Telephone

+86 13816508465

QUICK LINKS