+86 13816508465

Pump Knowledge

Oct. 20, 2025

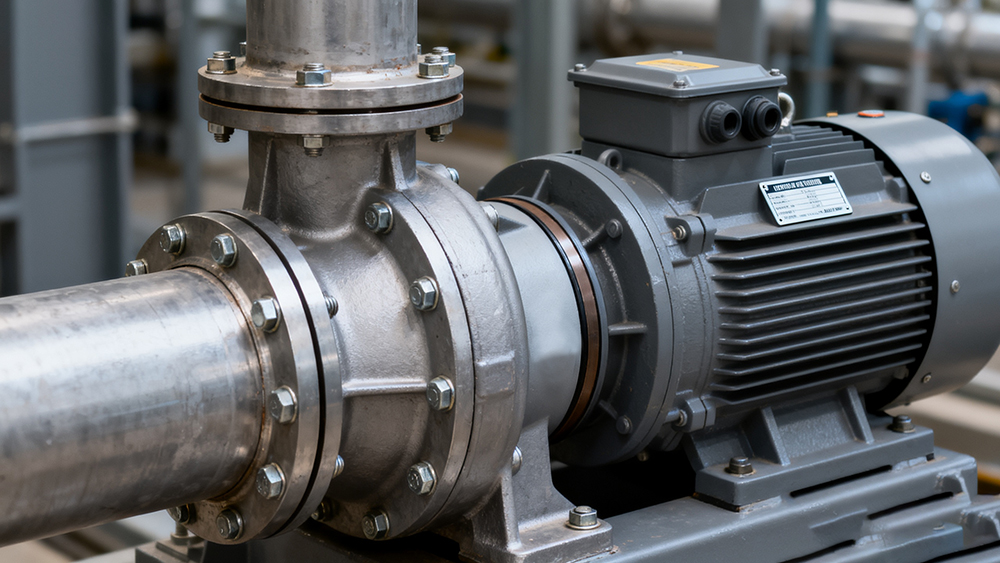

Starting a pipeline-connected centrifugal pump with the discharge valve closed is a fundamental best practice. This simple step protects the motor from overload, prevents hydraulic shocks in the piping system, and ensures a safe, controlled commissioning process. Understanding this procedure is essential for any technician, operator, or engineer working with industrial pump systems.

This practice applies specifically to centrifugal pumps, which are designed to handle this startup condition safely. By closing the outlet, you create a controlled environment that allows the pump and motor to reach stable operating parameters before introducing full flow and pressure into the system. This method minimizes mechanical and electrical stress, extending the life of your equipment.

Following a consistent, logical startup sequence is key to safe and efficient pump operation. Use this checklist to ensure all critical steps are completed correctly.

1. Pre-Startup Inspection: Before doing anything else, verify that all mechanical and safety checks are complete. Ensure all guards are in place, lubrication levels are correct, and the pump and motor are securely mounted.

2. Confirm Suction and Priming: Verify the pump is fully primed, meaning the casing is filled with liquid and all air has been bled from the system. Ensure the suction valve is fully open to allow an uninterrupted flow of liquid to the pump's impeller. Starting a pump dry will cause immediate damage to the mechanical seal and other components.

3. Close the Discharge Valve: Ensure the discharge (outlet) valve is completely closed. This is the most critical step for this procedure. It isolates the pump from the main piping system, allowing it to start under a no-flow condition.

4. Initiate Motor Start: Start the pump motor according to the manufacturer's instructions. If a variable frequency drive (VFD) or soft starter is installed, ensure its settings are configured for a smooth ramp-up.

5. Monitor Initial Operation: Immediately after startup, check the pressure gauge on the discharge side of the pump. You should see the pressure rise quickly and stabilize at the pump's shut-off head value. At the same time, monitor the motor's amperage draw; it should be at its lowest point on the pump's performance curve. Listen for any unusual noises, like grinding or cavitation, and check for excessive vibration.

6. Slowly Open the Discharge Valve: Once the pump is running smoothly against the closed valve, begin to open the discharge valve slowly. This allows the system to fill and pressurize in a controlled manner, preventing water hammer and sudden load changes on the motor.

7. Ramp Up to Operating Point: Continue to open the valve gradually while monitoring the motor current and system pressure. As the flow rate increases, the motor's amperage will rise. Stop opening the valve once you reach the desired flow rate or pressure for your system's operational needs.

8. Final System Check: With the pump at its duty point, perform a final check. Confirm that the motor current, pressure, and flow rate are all within their expected operating ranges. Listen again for any abnormal sounds and verify there are no leaks from the pump seals or piping connections.

Starting a centrifugal pump with the discharge valve closed places it at a specific point on its performance curve known as the 【shut-off head.】 At this no-flow condition, the pump builds maximum pressure (head), but the power required by the motor is at or near its minimum. This is because the pump is only moving the liquid within its casing, not pushing a large volume of fluid through the entire piping system.

This low-load start provides two major benefits:

1. Reduced Motor Stress: Starting a motor requires a significant inrush of current to overcome inertia. By starting the pump at its lowest power demand point (shut-off), you minimize the electrical load and thermal stress on the motor windings. This is especially important for large motors or in systems with sensitive electrical grids. As you slowly open the discharge valve, the load on the motor increases gradually, preventing a sudden, high-torque demand that could trip breakers or damage components.

2. Prevention of Hydraulic Shocks: When a pump starts and instantly sends a high-volume flow into an empty or partially pressurized pipe system, it can create a powerful hydraulic shock, or 【water hammer.】 This pressure wave can damage pipes, fittings, valves, and even the pump itself. Starting against a closed valve allows you to fill and pressurize the system gently, avoiding these destructive transients and ensuring a smooth transition to full operation.

Always prioritize safety and adhere to established guidelines when operating rotating equipment.

Follow the Manual: The manufacturer's instruction manual is the ultimate authority. Always consult it for specific startup procedures, recommended settings, and safety warnings related to your pump model.

Use Motor Controls: Whenever possible, use a soft starter or VFD. These devices provide superior control over the motor's acceleration, further reducing electrical and mechanical stress during startup.

Pump-Specific Rule: This procedure is for centrifugal pumps only. Never start a positive displacement pump (like a gear, lobe, or reciprocating pump) against a closed discharge valve. Doing so will cause a dangerous and rapid pressure buildup, leading to catastrophic failure of the pump or piping.

Priming is Non-Negotiable: Never start a centrifugal pump without ensuring it is fully primed. Running a pump dry will destroy the mechanical seal in seconds and can cause severe damage to the impeller and casing.

Monitor System Vents: Ensure any high-point vents in the suction line are properly managed to prevent air from becoming trapped, which can lead to cavitation and performance issues.

Even with a checklist, issues can arise. Here are common mistakes and how to address them.

Opening the Discharge Valve Too Quickly: This negates the benefits of a closed-valve start and can still cause a high current draw and water hammer. If the motor trips on overload, reset it and repeat the startup, this time opening the valve much more slowly.

Starting Without Priming: If the pump makes a loud grinding or rattling noise and fails to build pressure, it is likely running dry. Shut it down immediately. Allow the unit to cool, then re-prime the system completely before attempting another start.

Ignoring Abnormal Vibration or Noise: Excessive vibration or cavitation noise (sounding like gravel in the pump) upon startup indicates a problem. Shut the pump down. Check for air in the suction line, ensure the suction valve is fully open, and verify the impeller is not clogged with debris.

High Motor Current at Low Flow: If the motor's amperage is high while the discharge valve is still mostly closed, there may be a mechanical issue. Potential causes include misalignment, worn bearings, or a problem with the mechanical seal. Do not continue to run the pump; investigate the root cause.

Starting a pipeline-connected centrifugal pump with the discharge valve closed is a critical procedure that ensures a safer, more controlled startup. This technique protects the motor from electrical overload, prevents damaging hydraulic shocks, and allows for a smooth, gradual ramp-up to the system's operating point, ultimately extending equipment life and improving plant reliability.

Address

No.17 XeDa Jimei Ind. Park, Xiqing Economic Development Area, Tianjin, China

Telephone

+86 13816508465

QUICK LINKS