+86 13816508465

Pump Knowledge

Oct. 21, 2025

Starting a centrifugal pump might seem as simple as flipping a switch, but a critical preparatory step often gets overlooked: pump priming. Many believe that pumps can handle a bit of air, but this common misconception can lead to catastrophic equipment failure. The presence of air in the suction line or pump casing is a silent threat that can cause severe damage, reduce efficiency, and result in costly downtime.

This article will explain the importance of pump priming and detail the risks associated with air in your system. We will explore how to correctly prime a pump, identify signs of air-related problems, and provide preventive maintenance tips to ensure your equipment operates safely and reliably for years to come.

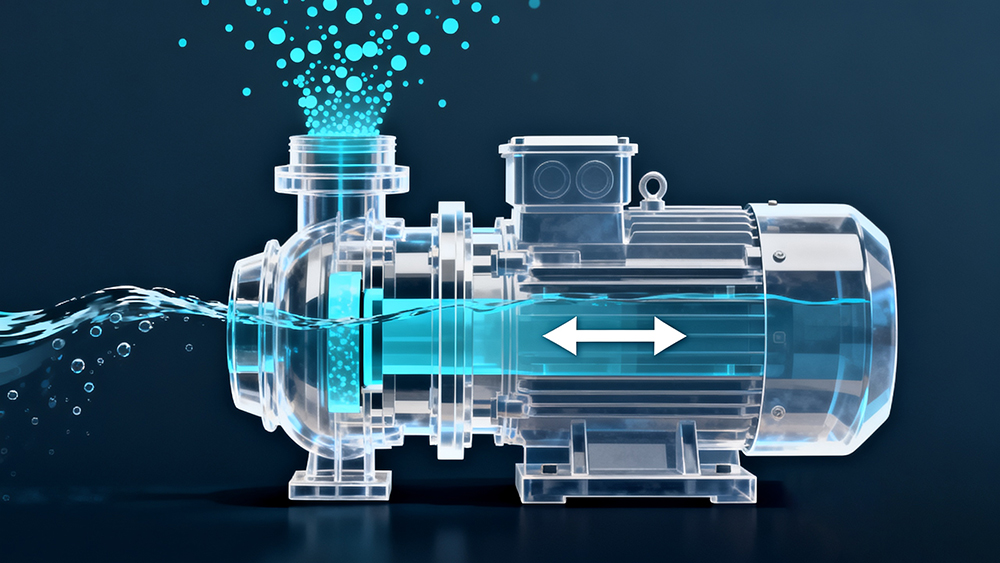

Pump priming is the process of removing all air, gas, or vapor from the pump and its suction line before starting the motor. The primary goal is to fill the pump casing and suction pipe completely with the liquid that will be pumped. This ensures that the pump's impeller—the rotating component that moves the fluid—is fully submerged.

Centrifugal pumps work by creating a pressure differential, but they are designed to move liquids, not gases. When the impeller is surrounded by liquid, its rotation generates the necessary low-pressure zone at the suction eye, drawing more fluid into the pump. If air is present, the impeller will just spin without creating this pressure difference, rendering the pump useless. While some specialized 【self-priming】 pumps can handle small amounts of air, most standard centrifugal pumps require manual priming for safe and effective operation.

Air within a hydraulic system introduces a range of problems that can quickly escalate from minor inefficiencies to complete pump destruction. Understanding these dangers is key to appreciating the need for proper centrifugal pump maintenance.

Cavitation Risk

One of the most destructive phenomena caused by air in a pump system is cavitation. When air pockets move from the low-pressure suction side to the high-pressure discharge side, they collapse violently. These implosions create intense shockwaves that hammer the impeller and pump casing. Over time, this process erodes the metal surfaces, creating pitting and cracks that compromise the pump's structural integrity and lead to premature failure.

Loss of Suction and Dry Running

A pump with air in its suction line cannot generate sufficient pressure to draw in liquid. This condition, known as losing prime, effectively stops the flow. If the pump continues to operate without fluid, it enters a state called 【dry running.】 The liquid being pumped also serves as a lubricant and coolant for the pump's internal components. Without it, friction generates immense heat, which can damage seals, bearings, and even warp the impeller, leading to costly repairs.

Overheating and Motor Stress

As friction builds up during dry running, the pump rapidly overheats. This excessive heat not only damages the pump itself but also puts significant strain on the motor. The motor will work harder to turn the impeller against the increased friction, potentially leading to an electrical overload and burnout. This is a common cause of motor failure in systems where pump priming is neglected.

Inconsistent Flow and Vibration

Air in the system reduces hydraulic efficiency, resulting in fluctuating pressure and inconsistent flow rates. This erratic operation causes significant vibration throughout the pump and the connected piping. Chronic vibration can loosen fittings, damage seals, and weaken pipe joints, creating a risk of leaks and further system failures. The rattling or knocking noises that often accompany this vibration are a clear warning sign that you need to prevent pump damage immediately.

Recognizing the symptoms of air intrusion is the first step toward troubleshooting and resolving the issue. Be alert for these common indicators:

Failure to Deliver Fluid: The most obvious sign is when the pump runs but fails to move any liquid or exhibits a significant drop in pressure.

Unusual Noises: A properly primed pump runs smoothly. Rattling, grinding, or knocking sounds often indicate cavitation caused by air pockets.

Excessive Vibration: If the pump or adjacent pipes are vibrating more than usual, it may be due to inconsistent flow caused by trapped air.

Overheating: If the pump casing or motor feels unusually hot to the touch, it could be a sign of dry running or increased strain from operating with air in the system.

Following the correct priming procedure is essential for protecting your equipment. While methods can vary based on system design, the fundamental principles remain the same.

1. Fill the Pump Casing: Before starting the motor, make sure the pump casing is completely filled with the liquid. Many pumps have a fill port on the top of the casing for this purpose. Pour liquid in until it overflows.

2. Ensure an Airtight Suction Line: Inspect all gaskets, fittings, and joints on the suction side of the pump. Even a tiny leak can allow air to be drawn into the system during operation.

3. Use a Foot Valve: A foot valve, which is a type of check valve installed at the end of the suction line, prevents liquid from draining back out of the pump and suction pipe when the pump is shut down. This keeps the pump primed for its next startup.

4. Install Priming Aids for Large Systems: For larger or more complex systems, automated priming solutions like vacuum pumps or dedicated priming pumps can be used to remove air before every startup.

If you suspect air has entered your system, you must remove it before operating the pump.

Use Bleed Valves: Open air release or bleed valves located at the highest points in the discharge piping and on the pump casing to allow trapped air to escape as the system fills with liquid

Manually Vent the Pump: Loosen a plug or fitting on top of the pump casing to vent any remaining air. You should hear a hissing sound as the air escapes, followed by a steady trickle of liquid.

Check Suction Line Slope: Ensure your suction piping is installed with a continuous upward slope from the liquid source to the pump. This design prevents air from getting trapped in high spots along the line.

Consistent maintenance is the best way to prevent issues related to air in a pump system.

Regularly inspect the suction line for leaks, paying close attention to flanges, unions, and valve stems.

Keep strainers and filters on the suction side clean. A clogged strainer can restrict flow and cause the pump to draw in air.

Always consult and follow the manufacturer's specific priming instructions for each pump model you operate.

Proper pump priming is a non-negotiable step for the safe and efficient operation of centrifugal pumps. Failing to remove air from the system exposes your equipment to destructive forces like cavitation, overheating, and mechanical stress. These issues lead to poor performance, unexpected failures, and expensive repairs.

By understanding the dangers of air in a pump system and implementing correct priming and maintenance procedures, you can ensure a smooth startup, protect your investment, and guarantee the long-term reliability of your fluid handling systems. A well-primed pump is a healthy and efficient pump.

Address

No.17 XeDa Jimei Ind. Park, Xiqing Economic Development Area, Tianjin, China

Telephone

+86 13816508465

QUICK LINKS