+86 13816508465

Pump Knowledge

Oct. 21, 2025

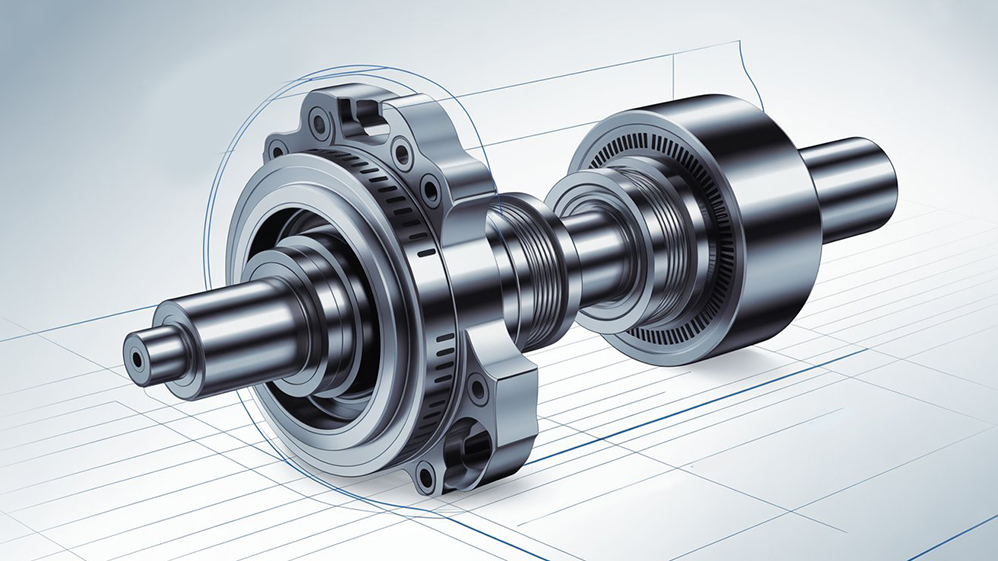

Proper motor and pump alignment is a cornerstone of industrial maintenance, directly impacting system efficiency, reliability, and lifespan. When a pump and its motor are installed, their shafts must be precisely aligned so they rotate on a common axis. Misalignment, even by a fraction of a millimeter, introduces destructive forces that cause excessive vibration, premature wear on bearings and seals, and significant energy loss.

This guide will explain the fundamentals of shaft alignment, its critical importance, and the consequences of getting it wrong. We will cover various alignment methods, from traditional techniques to modern laser systems, and provide a step-by-step procedure for achieving a precise setup. Understanding these principles is a key part of any effective pump installation and maintenance strategy.

Shaft alignment is the process of positioning the rotational centers of two or more shafts—in this case, the pump and its motor—so they are collinear when the machine is running under normal operating conditions. The goal is to ensure that the power from the motor is transmitted to the pump smoothly and efficiently through the coupling.

There are two primary types of misalignment:

Parallel (Offset) Misalignment: This occurs when the centerlines of the motor and pump shafts are parallel but not on the same axis. Imagine two perfectly level but offset shafts.

Angular Misalignment: This occurs when the shafts are at an angle to each other. One shaft might be pointing slightly up or down, or left or right, relative to the other.

In reality, most misalignment issues are a combination of both parallel and angular deviations. Even small amounts of misalignment can create significant cyclical stress on the shafts, couplings, bearings, and seals every single rotation. This is why precise motor and pump alignment is not just a recommendation but a necessity.

Ignoring shaft alignment is a recipe for costly, unplanned downtime. The constant stress created by misalignment manifests in several destructive ways.

Increased Vibration and Noise

Misalignment is one of the leading causes of excessive machinery vibration. As the shafts rotate out of sync, the coupling is forced to flex continuously, creating vibration that radiates throughout the pump, motor, and baseplate. This not only generates disruptive noise but also puts mechanical stress on all connected components. The goal is always to prevent equipment vibration before it starts.

Excessive Bearing and Seal Wear

The vibration and cyclical loads from misalignment are directly transferred to the bearings of both the pump and the motor. This leads to accelerated wear and drastically shortens their operational life. It is estimated that shaft misalignment is responsible for over 50% of all rotating machinery failures, with bearing failure being the most common symptom. Similarly, the flexing of the shaft can cause mechanical seals to open and close, allowing leaks and leading to premature failure.

Coupling Failure and Energy Loss

Flexible couplings are designed to accommodate a very small degree of misalignment, but they are not a cure for it. When forced to compensate for significant misalignment, the coupling itself will wear out quickly and fail. Furthermore, the energy required to constantly flex the coupling and overcome the vibrational forces is wasted, leading to increased power consumption and higher operational costs.

Shortened Equipment Lifespan

The cumulative effect of vibration, bearing wear, and seal damage is a significantly reduced service life for both the pump and the motor. A machine that should last for decades might fail in a matter of months or even weeks if operated with poor alignment.

Several methods are used for motor and pump alignment, ranging from basic checks to highly accurate digital measurements.

Straightedge and Feeler Gauge: This is the most basic method. A straightedge is placed across the two coupling hubs, and feeler gauges are used to measure any gaps. While it is inexpensive and useful for initial rough alignment, it is not precise enough for most modern industrial applications.

Dial Indicator Method: This technique uses one or more dial indicators mounted to one shaft to measure the relative movement of the other shaft as they are rotated. Reverse-dial and rim-and-face are common setups. This method is far more accurate than a straightedge but requires significant skill and time to perform correctly.

Laser Alignment Systems: This is the industry standard for precision. Laser alignment tools consist of a laser emitter mounted on one shaft and a detector on the other. As the shafts are rotated, the system measures the exact position of the laser beam and calculates the precise adjustments needed. This method is fast, extremely accurate, and less prone to human error.

Before any alignment method is used, a soft foot check is mandatory. Soft foot occurs when one of the motor's feet does not sit flat on the baseplate. Attempting to perform an alignment without correcting this will lead to inaccurate readings and a failed alignment.

A successful alignment follows a structured, methodical process.

1. Preparation and Safety: Ensure the equipment is locked out and tagged out to prevent accidental startup. Clean the area around the motor feet and baseplate.

2. Initial Inspection: Check for and correct any soft foot by shimming the appropriate motor foot until all four feet are sitting level and solid. Inspect the coupling for wear or damage and replace it if necessary.

3. Rough Alignment: Use a straightedge to perform a rough alignment. Adjust the motor's position until the shafts are visually close to being aligned. This saves time during the fine-tuning stage.

4. Fine Alignment: Set up your dial indicators or laser alignment tools according to the manufacturer's instructions. Slowly rotate both shafts together and take your measurements.

5. Adjust Motor Position: Based on the readings from your alignment tool, make vertical and horizontal adjustments. Use pre-cut, high-quality shims to raise the motor for vertical corrections. Use jacking bolts or gentle tapping to move the motor horizontally.

6. Tighten and Recheck: Tighten the motor's hold-down bolts in a cross pattern to prevent the alignment from shifting. Once tightened to the correct torque, perform one final measurement to verify that the alignment is still within tolerance.

7. Record the Results: Document the final alignment values in your maintenance log. This data is valuable for tracking trends and troubleshooting future issues.

Having the right tools is essential for an accurate and efficient alignment job.

Precision Tools: Feeler gauges, dial indicators with magnetic bases, or a complete laser alignment system.

Hand Tools: A torque wrench for proper bolt tightening, a set of combination wrenches, and a straightedge.

Alignment Aids: A set of high-quality, pre-cut stainless steel shims, and a precision level.

Reference Materials: The equipment manufacturer's alignment tolerance guidelines or standard alignment charts.

Alignment is not a one-time event. It should be part of a comprehensive maintenance strategy.

Recheck Alignment Regularly: Check alignment after the foundation has settled (on new installations), after a major vibration event, or as part of your annual preventive maintenance schedule.

Monitor Vibration: Use regular vibration analysis to detect developing misalignment issues before they become catastrophic.

Don't Rely on Flexible Couplings: While flexible couplings are necessary, they should never be used as a 【fix】 for poor alignment. Always align to the tightest possible tolerance.

Address Thermal Growth: For equipment that operates at high temperatures, consider performing a 【hot alignment】 check to account for thermal expansion that can alter the alignment from its cold state.

Even experienced technicians can make mistakes. Watch out for these common pitfalls.

Ignoring Soft Foot: This is the most common cause of failed alignment jobs.

Introducing Bolt-Bound Conditions: Overtightening bolts before the alignment is complete can distort the machine frame and give false readings.

Failing to Realign After Repairs: Always verify alignment after replacing a pump, motor, coupling, or bearings.

Using Damaged or Low-Quality Shims: Bent or rusty shims can lead to an incorrect soft foot condition and inaccurate adjustments.

Precise motor and pump alignment is a foundational element of a reliable plant. It is a direct investment in equipment longevity, operational efficiency, and workplace safety. By minimizing vibration and mechanical stress, proper alignment extends the life of bearings, seals, and couplings, reduces energy consumption, and prevents costly, unexpected failures.

While traditional methods have their place, the accuracy and efficiency of modern laser alignment tools make them an invaluable asset for any maintenance team. By embracing precision, following best practices, and making alignment a core part of your maintenance culture, you can ensure your rotating equipment runs smoothly and reliably for years to come.

Address

No.17 XeDa Jimei Ind. Park, Xiqing Economic Development Area, Tianjin, China

Telephone

+86 13816508465

QUICK LINKS