+86 13816508465

Jul. 24, 2025

Industrial and commercial sectors rely on various types of pumps—submersible, centrifugal, sewage, and more—to keep operations running smoothly. Pump durability and reliability are critical for minimizing downtime and controlling long-term operational costs. Yet, pumps frequently operate in harsh environments. Exposure to moisture, chemicals, and abrasive materials takes a toll on their functionality.

What if there were a way to dramatically extend the life of your pumps while reducing maintenance costs? Enter electrophoretic coating (E-coating)—a revolutionary surface treatment that enhances both pump durability and corrosion resistance. This article will explore E-coating technology and reveal why it's an invaluable solution for pump procurement managers, maintenance teams, and industrial professionals.

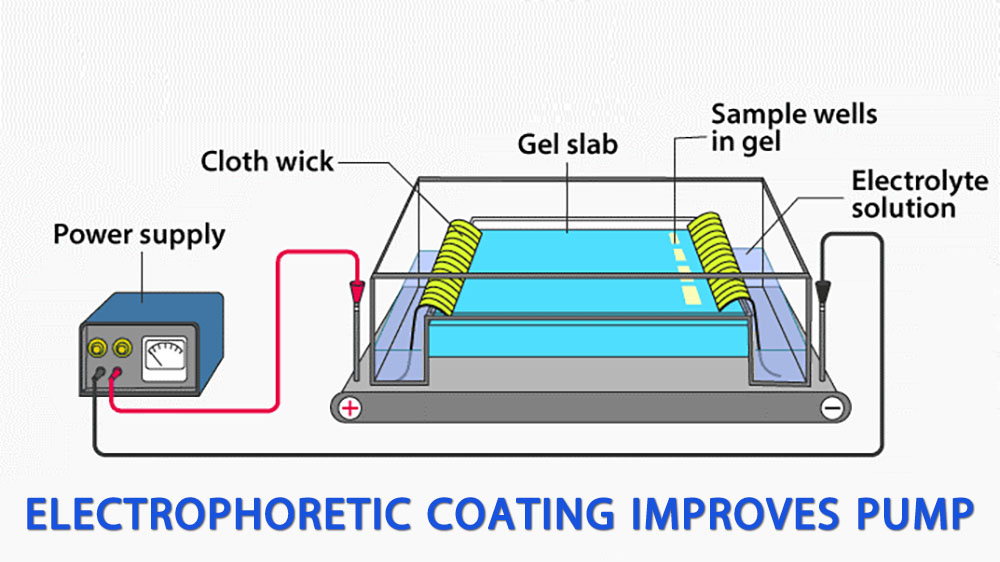

Electrophoretic coating, commonly referred to as E-coating, is an advanced surface treatment process in which a water-based solution containing paint particles is applied to a metal surface through electro-deposition. During this process, electrical charges attract paint particles to the metal surface, creating a uniform and consistent coating.

This method stands out from traditional coating technologies like powder coating or spray painting. Here's why:

Precision: E-coating forms an even layer across even the most complex geometries, reaching crevices and corners that other methods often miss.

Versatility: While widely used in automotive and agricultural industries, it's increasingly recognized for its applications in industrial pump manufacturing.

Durability: The coatings created are robust, offering enhanced resistance to corrosion and mechanical stress.

E-coating's rising popularity in industrial applications highlights its ability to balance superior performance with eco-friendly manufacturing practices.

E-coating directly addresses some of the most pressing challenges faced by pump users today, particularly in environments where rust, chemical exposure, and abrasion are constant threats. Here’s why it deserves your attention:

Corrosion Resistance: Non-coated or inadequately protected pumps are prone to rust. E-coating forms a protective barrier that shields metal surfaces from moisture, salts, and other corrosive elements.

Reduced Maintenance Costs: Over time, rust and surface degradation lead to functional issues. Pumps treated with an anti-corrosion coating like E-coating require less frequent servicing, lowering maintenance expenses.

Long-Term ROI: From a procurement perspective, purchasing E-coated pumps ensures a longer lifespan and greater value for every dollar spent. When fewer breakdowns occur, downtime and replacement costs are also minimized.

Investing in E-coated pumps can transform operational efficiency while protecting your budgets and resources over the long term.

1. Superior Corrosion Resistance

The uniform layering of E-coating provides complete coverage, even on hard-to-reach areas like pump casings, blades, and impellers. This makes it an excellent defense against corrosion, particularly in industrial and municipal settings where pumps are exposed to water and chemicals.

The protective barrier isn't limited to ordinary environments. For example, pumps used in wastewater treatment facilities or saline-rich coastal regions particularly benefit from E-coating's ability to repel corrosive agents.

2. Enhanced Mechanical Durability

The durability of E-coating doesn't stop at corrosion resistance. It also fortifies pumps against abrasive damage and chipping caused by routine wear and tear. This reinforces performance under extreme conditions, such as in construction sites or mining operations.

An E-coated pump can survive significant operational challenges while maintaining its structural integrity—a critical feature for industrial equipment exposed to mechanical stresses daily.

3. Eco-Friendly and Cost-Efficient

Unlike traditional coating techniques that may rely on solvent-heavy paints, E-coating offers an eco-friendly alternative. It uses a water-based formula, drastically reducing volatile organic compound (VOC) emissions.

Additionally, the efficiency of the E-coating process ensures minimal waste, allowing businesses to adopt environmentally responsible practices without sacrificing quality. Lower VOC emissions and reduced maintenance requirements also translate into savings over the long term, benefiting rental services and maintenance providers.

The versatility of E-coating makes it suitable for various pump categories, including:

Submersible Pumps: Often operating underwater, these pumps require exceptional resistance to corrosion and wear.

Centrifugal Pumps: Frequently used for liquid transfer in industrial settings, E-coating ensures longevity even in demanding applications.

Trash and Sewage Pumps: These operate in heavily abrasive and corrosive environments, making additional surface protection crucial.

Industrial Water Pumps: E-coating ensures consistent performance across diverse industries, from manufacturing to agriculture.

Whether you focus on pump procurement, maintenance, or rental services, incorporating E-coating technology into your selection criteria ensures better reliability across all pump types.

To highlight the value of E-coating, here's a comparison of how it stacks up against other common surface treatment options:

Feature | E-Coating | Powder Coating | Galvanization | Epoxy Paint |

Coverage Consistency | Excellent, even on complex geometries | Limited in tight areas | Moderate, depends on thickness | Moderate |

Corrosion | High | Moderate | High | Moderate |

Durability | Strong against abrasion | Mid-tier | High | Mid-tier |

Eco-Friendliness | Water-based, low VOC | Requires heat, some VOC | Uses zinc, potentially toxic | Solvent-based |

Cost-Efficiency | High | Moderate | High upfront cost, long ROI | Moderate |

For pump applications requiring a balance of coverage, durability, and eco-friendliness, E-coating outperforms competing technologies.

If you're considering E-coated pumps for your facilities, here's a checklist to guide your procurement process:

Coating Certification: Confirm whether the E-coating process meets relevant industry standards.

Application: Ensure critical parts—such as impellers, casings, and seals—are adequately treated.

Supplier Reputation: Partner with manufacturers that specialize in E-coating for industrial equipment.

Testing Procedures: Verify that the coating has undergone abrasion and corrosion resistance testing.

A thorough review of these elements guarantees you're investing in quality-driven solutions that will drive long-term success.

Electrophoretic coating is a game-changer for pump procurement managers, maintenance teams, and industrial operators. With its unmatched corrosion resistance, mechanical durability, and eco-friendly advantages, E-coating enhances pump lifespan while significantly reducing operational costs.

If you're looking to maximize reliability in your next pump purchase or project, make E-coated pumps your top priority. Don't settle for surface treatments that compromise performance—opt for technology that delivers value in challenging environments.

Need pumps built for durability and corrosion resistance? Ensure your selection includes electrophoretic coating for a smarter, more reliable investment.

Address

No.17 XeDa Jimei Ind. Park, Xiqing Economic Development Area, Tianjin, China

Telephone

+86 13816508465

QUICK LINKS