+86 13816508465

Pump Knowledge

Sep. 19, 2025

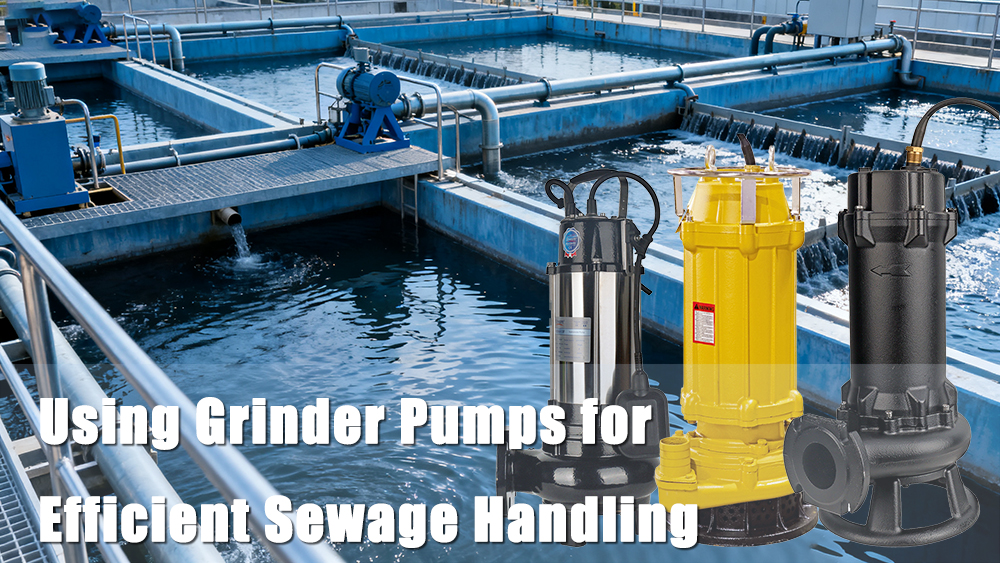

Dealing with sewage in remote or rural properties presents unique challenges. Without access to municipal sewer lines, homeowners and developers must find reliable, self-contained solutions. Standard gravity-fed systems often aren't an option due to terrain, distance, or elevation. This is where grinder pumps provide an efficient and modern answer to wastewater management. They play a vital role in moving sewage from a property to a septic tank or pressurized main line, ensuring clean and safe living conditions no matter the location.

This post will explore the world of grinder pumps. We'll cover what they are, how they work, and why they are often the best choice for remote properties. You will learn about their key applications, what to look for when choosing one, and best practices for installation and maintenance.

A grinder pump is a specialized wastewater pump designed to handle raw sewage. Unlike standard sewage pumps that only move liquid, a grinder pump uses a powerful cutting mechanism to shred solids like toilet paper and human waste into a fine slurry. This slurry can then be easily pumped through small-diameter pipes over long distances or uphill.

The operating principle is straightforward. Wastewater from toilets, showers, and sinks flows into a holding tank or basin where the pump is located. When the liquid level rises to a set point, a float switch activates the pump. The motor powers both the cutting blades and an impeller. The cutters shred the solids, and the impeller pushes the resulting slurry out of the basin and through the discharge pipe toward its destination.

The main difference between grinder pumps and other sewage pumps, like effluent or solid-handling pumps, is this grinding ability. Standard pumps are designed for liquids with minimal solids and can clog easily if they encounter anything more substantial. A grinder pump’s ability to liquefy waste makes it a far more robust solution for handling residential sewage.

Key Components of a Grinder Pump

Cutting Mechanism: A set of sharp, rotating blades made of hardened steel that macerates solids.

Impeller: A spinning device that pressurizes the slurry and forces it out of the pump.

Motor: The power source that drives both the cutters and the impeller, sealed in a waterproof housing.

Housing: A durable, submersible casing, usually made of cast iron or stainless steel, that protects the internal components.

Grinder pumps offer several distinct advantages that make them ideal for properties located far from city infrastructure.

Handles Solids to Prevent Clogs

The primary benefit is the ability to handle solids effectively. By turning waste into a fine slurry, grinder pumps drastically reduce the risk of clogs in the discharge pipes. This is crucial for systems that rely on narrow pipes or have to push wastewater over a significant distance.

Enables Long-Distance and Uphill Sewage Transport

Gravity is not always on your side. For properties situated below the level of the septic tank or main sewer line, or those located hundreds of feet away, a grinder pump is essential. It creates the pressure needed to move wastewater uphill and across challenging landscapes, something a gravity system simply cannot do.

Compact and Versatile Design

Grinder pumps are designed for residential and small community use. The pump and its basin are compact and can be installed underground with minimal disruption to the landscape. This makes them a discreet and effective solution for single homes or small clusters of buildings.

Reduces Risk of Costly System Failures

A clogged or failed sewage system is a messy, expensive, and hazardous problem. By ensuring that waste is properly processed and transported, grinder pumps protect the integrity of the entire septic or sewer system. This reliability provides peace of mind and prevents costly emergency repairs.

The versatility of grinder pumps makes them suitable for a wide range of applications outside of urban centers.

Single Homes: For any house that is too far from or sits at the wrong elevation to connect to a municipal sewer system, a grinder pump is a common solution to move waste to a private septic system.

Small Communities and Off-Grid Developments: Groups of homes, cabins, or tiny home villages can use a shared, pressurized sewer main fed by individual grinder pumps at each residence. This is often more cost-effective than installing a full gravity sewer system.

Vacation Cabins, Farms, and Lakefront Properties: These properties often have challenging terrain, like steep slopes or high water tables. Grinder pumps allow for flexible placement of both the structure and the septic field.

Basement Bathrooms: Even in homes connected to a city sewer, a grinder pump can be used to add a bathroom in a basement that is below the main sewer line.

Choosing the right grinder pump is critical for long-term performance. Here are the key factors to consider.

Pump Capacity

You need to calculate the flow rate (gallons per minute) and the total dynamic head (the vertical and horizontal distance the slurry must travel, plus friction loss). An undersized pump will fail to move the waste effectively, while an oversized pump wastes energy. A professional can help you determine the right specifications for your property's layout.

Material Options

The pump's housing material affects its durability. Cast iron is a popular choice for its strength and longevity. For applications with corrosive water or soil, stainless steel offers superior resistance to rust and degradation, extending the pump's life.

Inlet and Outlet Sizes

The pump's inlet and outlet connections must match the diameter of your system's pipes. A common discharge pipe size for a grinder pump is 1.25 to 2 inches, which is much smaller than the 3- or 4-inch pipes used in gravity systems.

Power Source

Most residential grinder pumps run on a standard single-phase power supply (120V or 240V). Larger systems for communities may require a more powerful three-phase motor. In remote areas prone to power outages, consider a model that is compatible with a backup generator.

Noise Levels

While grinder pumps are installed in a basin, some noise and vibration are unavoidable. If the pump is located near living areas, look for models designed for quieter operation to minimize disturbances.

Proper installation and routine maintenance are essential for ensuring your grinder pump operates reliably for years to come.

Proper Pit Sizing and Location

The basin or pit that holds the pump must be large enough to handle the expected inflow without causing the pump to cycle too frequently, which can burn out the motor. It should be located in an accessible spot for future maintenance.

Venting and Check Valves

The system must be properly vented to allow sewer gases to escape. A check valve should be installed in the discharge line to prevent wastewater from flowing back into the basin after the pump shuts off.

Routine Inspection

Periodically inspect the pump and basin. Check that the float switches move freely and are not obstructed by grease or debris. Listen for unusual noises that might indicate a problem with the motor or cutters. Most experts recommend a professional inspection every one to two years.

Alarm Systems

An alarm system is a must-have. It will alert you with a light or audible sound if the water level in the basin gets too high, signaling a pump failure or power outage. This early warning can help you prevent a messy overflow.

Lifespan and Replacement

A well-maintained grinder pump can last 10 to 15 years or more. When it's time for a replacement, be sure to choose a model with similar performance specifications to ensure it integrates smoothly with your existing system.

For remote properties where gravity-flow sewage systems are not feasible, grinder pumps offer a powerful and reliable solution. By grinding solid waste into a manageable slurry, they prevent clogs, enable pumping over long distances and uphill, and protect the health of your entire wastewater system. Their efficiency and adaptability make them an indispensable technology for modern rural and off-grid living.

As technology advances, we can expect to see even smarter grinder pumps with integrated monitoring systems and more energy-efficient motors. These innovations will continue to make remote wastewater management easier and more dependable than ever before.

Address

No.17 XeDa Jimei Ind. Park, Xiqing Economic Development Area, Tianjin, China

Telephone

+86 13816508465

QUICK LINKS