+86 13816508465

Pump Knowledge

Dec. 15, 2025

Float switches are one of the simplest yet most important components in a pump control system. Whether you're managing drainage pumps, borehole pumps, sewage pumps, or water storage tanks, choosing the right float switch ensures reliable automation and long-term safety.

This guide helps you quickly understand how float switches work, how to choose them, and what technical parameters really matter—based entirely on real engineering principles and reliable product data.

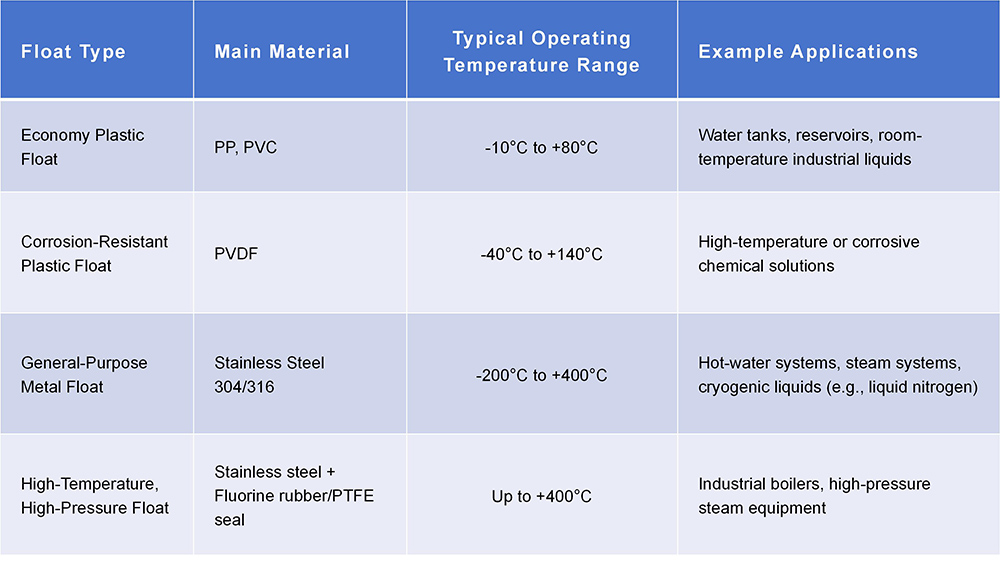

A float switch's maximum working temperature is not determined by the float ball alone—it depends on the weakest heat-resistant component within the whole structure.

When evaluating working temperature, always confirm these four points:

1.1 Maximum Temperature

What is the highest temperature your system may reach at any moment?

1.2 Continuous Working Temperature

What is the temperature during long-term, normal operation?

1.3 The Medium

Is the float switch used in:

clean water

sewage

oil

chemical liquids

hot water or steam

Different media require different float materials.

1.4 Float Material & Seal Material

Often the seal ring (not the float body) is the true temperature bottleneck.

Final takeaway:

The upper temperature limit is determined by the least heat-resistant part—usually the seal.

Always check the manufacturer's datasheet for the exact permissible temperature range.

Partly yes—but not entirely.

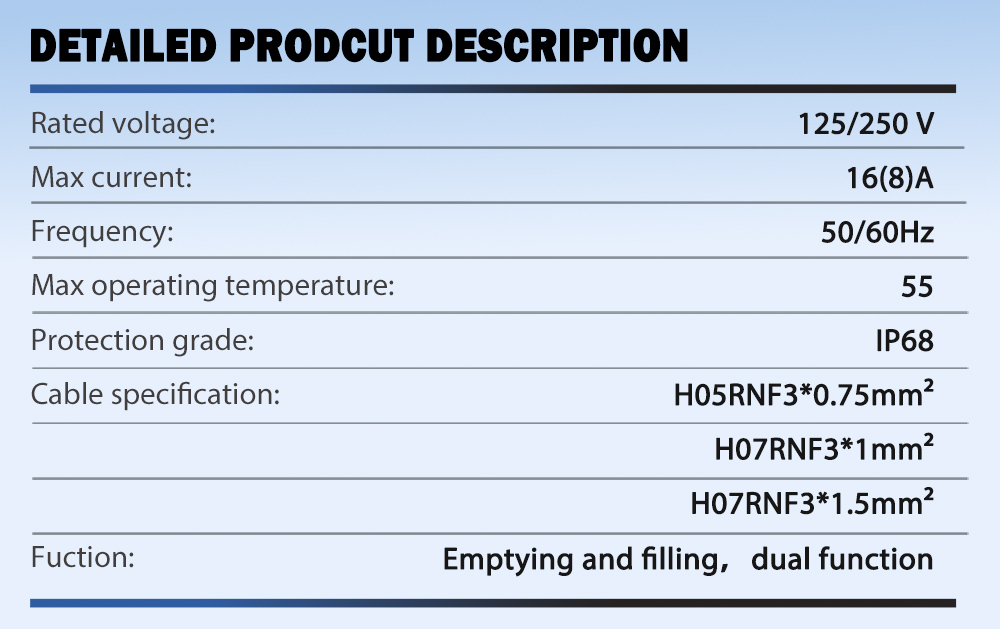

Many users assume 【thicker wires = higher power】 but for float switches, the real limiting factor is usually the internal contact capacity.

A float switch's maximum load depends on:

Internal wire diameter (conductor size)

This determines how much current the wire can safely carry.

Internal switch contact rating (the most critical factor)

Inside the float is a mechanical microswitch or reed switch.

Even if you use thick wires, if the contact is rated for only 1A,then the entire float switch can handle only 1A—not more.

Insulation material

Both wires and contacts generate heat; insulation must withstand it.

Always follow three steps:

Step 1 – Check the manufacturer's datasheet

Look for:

Contact rating: e.g., 10(2)A 250V AC

Wire spec: e.g., 0.75mm²

Step 2 – Calculate your load's current

For pumps and solenoid valves:

I = Power (W) ÷ Voltage (V)

Step 3 – Ensure safety margin

Choose a float switch where:

contact rating and wire capacity are both 20–30% higher than the load current.

Even with 1.5mm² wires, the real limit still depends on contact rating.

Most likely (typical float switch): 10A contact

Max Power = 220V × 10A = 2200W

This is the most common and practical maximum power.

You should select pumps ≤ 2200W for safe long-term operation.

If the float switch uses lower-grade contacts (5A)

Max Power = 220V × 5A = 1100W

Some smaller or low-cost float switches fall into this category.

Choosing the right float switch is not complicated—just follow these principles:

Working Temperature

Match the float and seal materials to your liquid temperature.

Maximum Load Power

Always refer to contact capacity, not just wire thickness.

Confirm Actual Load Current

Make sure the float's rating > pump's rated current.

Leave Safety Margin

20–30% reserve ensures reliability and longer lifespan.

Datasheet is King

Always trust the specifications provided by the manufacturer.

Why This Matters for Pump Systems

Incorrect float selection may lead to:

pump not switching off

motor overheating

contact welding

premature float failure

safety risks in sewage/wastewater systems

For dealers, installers or engineering buyers, proper float switch selection reduces after-sales issues and ensures stable system operation.

Streampumps provides reliable float switches and pump control solutions for:

sewage pumps

drainage pumps

borehole pumps

water tanks

industrial automation

Address

No.17 XeDa Jimei Ind. Park, Xiqing Economic Development Area, Tianjin, China

Telephone

+86 13816508465

QUICK LINKS