+86 13816508465

Pump Knowledge

Aug. 15, 2025

End suction pumps are an essential piece of equipment in various industries. From water treatment plants to HVAC systems, these pumps play a crucial role in transferring fluids efficiently. To optimize their performance and longevity, understanding their key components and internal flow path is vital.

This knowledge not only aids in proper operation but also ensures timely maintenance and effective troubleshooting. Below, we'll break down the main components of an end suction pump and explain how the flow path works step by step. We'll also provide insights into common design variations and maintenance tips.

End suction pumps are one of the most common pump types, characterized by their simple design and straightforward operation. They consist of a single impeller mounted on a horizontal shaft. Fluid enters through a suction nozzle at one end and exits through the discharge nozzle at the top.

These versatile pumps are widely used across industries including agriculture, manufacturing, oil and gas, and municipal water systems. Applications range from irrigation and cooling systems to handling chemicals or wastewater. Their compact size, affordability, and adaptability make them a go-to choice for a variety of fluid-transfer tasks.

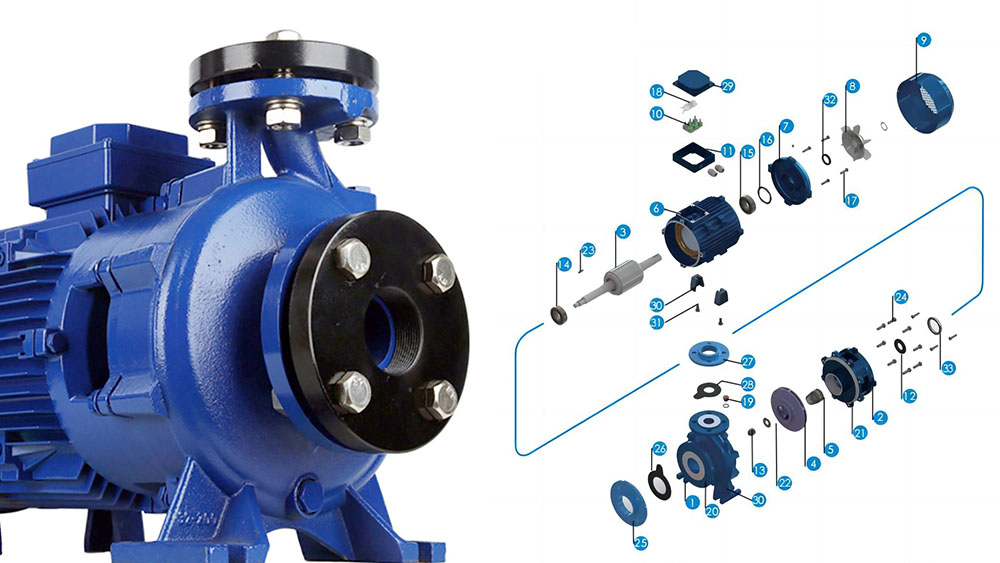

Every end suction pump relies on a series of components working in harmony. Each part contributes to the pump’s efficiency and overall functionality. Below, we'll explore the primary components and their roles.

1. Casing

The casing, often designed in a volute or concentric shape, directs fluid flow within the pump. Its primary purpose is to protect the internal mechanisms and channel the fluid toward the discharge nozzle while maintaining pressure.

2. Impeller

The impeller is the heart of an end suction pump. It can come in open, semi-open, or closed designs, depending on the application. Its primary function is to transfer energy from the motor to the fluid, increasing the fluid velocity and pressure.

3. Shaft

The shaft connects the impeller to the motor or driver, transmitting mechanical power. A properly aligned shaft ensures smooth rotation and consistent energy transfer.

4. Bearing Assembly

Bearings support the shaft and reduce friction during rotation. They play a critical role in maintaining the mechanical integrity of the pump by preventing wear and tear from excessive vibration.

5. Mechanical Seal or Packing

These components prevent fluid leakage along the shaft. Mechanical seals are favored for modern pumps due to their efficiency and reliability, though packing is still used in some applications.

6. Wear Rings

Wear rings protect both the casing and the impeller from erosion caused by fluid abrasion. They serve as a buffer between critical components, extending the pump's lifespan.

7. Suction and Discharge Nozzles

The suction nozzle is where the fluid enters the pump, while the discharge nozzle channels it toward the downstream system. Properly designed nozzles minimize turbulence and maximize efficiency.

8. Motor or Driver

End suction pumps are typically powered by an electric motor, though diesel engines or other drivers can be used depending on the application. The motor provides the rotational energy needed for impeller movement.

Now that we've covered the components, let’s explore how the fluid moves through an end suction pump step by step.

1. Suction Stage

The process kicks off as fluid enters the pump through the suction nozzle. It passes into the eye of the impeller, where the transfer of energy begins.

2. Energy Conversion

Once inside the impeller, the rotating blades accelerate the fluid. This motion converts mechanical energy from the motor into kinetic energy, increasing the fluid’s velocity.

3. Volute Casing

The volute casing slows the fluid down, converting its kinetic energy into pressure energy. This stage is crucial for creating the high-pressure output needed to move the fluid through the system.

4. Discharge Stage

Finally, the fluid exits the pump through the discharge nozzle with increased pressure, ready to flow into the connected system.

End suction pumps come in various configurations that can alter their flow path and performance. Understanding these design variations is essential for selecting the right pump for your needs.

Single vs. Double Volute Designs

Single volute designs are suitable for smaller pumps, while double volute configurations balance internal forces in larger pumps, reducing wear on the casing and shaft.

Horizontal vs. Vertical Mounting

Horizontal mounting is standard for most applications, but vertical mounting is used where space is limited or when the pump needs to operate below the fluid’s surface.

Impeller Trim

The impeller’s diameter can be trimmed to adjust the pump's flow rate and efficiency. Customizing the impeller allows it to meet specific system requirements.

Despite their efficiency, end suction pumps can encounter problems over time. Here are some common issues and their causes:

Cavitation

Cavitation occurs when air bubbles form in the suction area due to low pressure. These bubbles can implode, causing damage to the impeller and reducing performance.

Wear Ring Erosion

Fluid abrasion can wear down the wear rings over time, compromising their ability to protect critical components.

Seal Leaks

Faulty or worn mechanical seals can lead to fluid leakage, disrupting system performance and increasing maintenance costs.

Impeller Damage or Clogging

Debris in the fluid can cause impeller damage or blockages. Regular inspections can prevent such issues.

Routine maintenance is essential for any end suction pump. Here are some practical tips to keep your pump in top condition:

Inspect Critical Components Regularly

Check the impeller, seals, and bearings for signs of wear and replace them as needed.

Ensure Proper Alignment

Misalignment between the motor and pump can lead to vibration and premature wear. Use alignment tools to confirm proper setup.

Monitor Vibration and Noise

Unusual noises or excessive vibration can be early signs of component failure. Address these issues promptly to avoid costly repairs.

End suction pumps rely on carefully designed components working together to move fluid efficiently. By understanding the flow path and keeping up with regular maintenance, you can ensure your pump operates at peak performance for years to come.

Whether you're selecting a pump for a new application or troubleshooting an existing one, knowing how the components interact and how the flow path operates is invaluable. Take care of your pump, and it will take care of your system.

Address

No.17 XeDa Jimei Ind. Park, Xiqing Economic Development Area, Tianjin, China

Telephone

+86 13816508465

QUICK LINKS