+86 13816508465

Pump Knowledge

Dec. 29, 2025

When an end suction pump fails, maintenance teams often point to worn bearings or a leaking mechanical seal. While these components are frequent culprits, the root cause is often traced back to a small but essential part: the pump coupling. A poorly chosen or misaligned coupling can silently transfer destructive forces throughout the entire pump assembly.

For engineers and maintenance professionals, understanding the coupling is key to extending service life and improving system reliability. A correctly selected and aligned coupling ensures smooth power transmission from the motor to the pump, protects sensitive rotating parts, and even reduces energy consumption.

This guide provides a practical explanation of what end suction pump couplings do, the different types available, proper alignment techniques, and how to troubleshoot common problems.

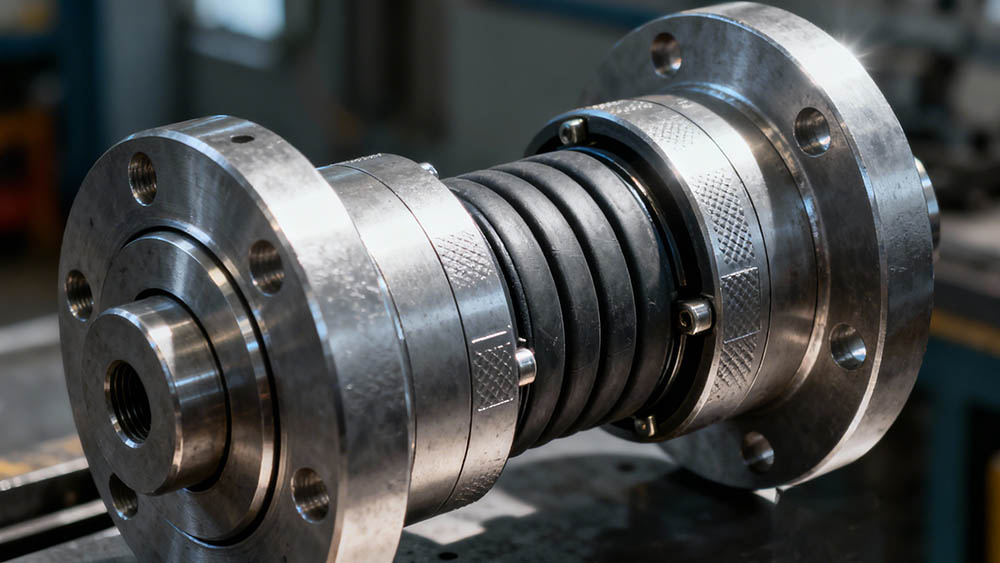

A coupling is a mechanical device that connects the motor shaft to the pump shaft. Its primary job is to transmit torque, but its secondary role is just as important: accommodating the minor, unavoidable misalignment between the two shafts.

In a typical end suction pump setup, the pump and motor are mounted on a shared baseplate. While they appear to be a single, rigid unit, they are subject to various operational stresses, including:

Vibration during operation

Thermal expansion as components heat up

Minor shifts or settling of the foundation

Pipe strain pulling on the pump casing

The coupling acts as a flexible link, absorbing these stresses and protecting critical components like bearings and mechanical seals from premature failure.

Unlike close-coupled pumps where the impeller mounts directly onto the motor shaft, end suction pumps depend on field alignment. This alignment is never perfect or permanent. Without a suitable coupling to bridge the gap, even the slightest misalignment can create a cascade of problems.

Excessive Vibration: Misalignment forces the shafts to fight each other, creating vibration that can damage the entire system.

Premature Bearing Failure: Bearings are designed to handle radial and axial loads, but the cyclical stress from misalignment causes them to overheat and fail quickly.

Leaking Mechanical Seals: A wobbling shaft prevents the mechanical seal faces from staying in perfect contact, leading to persistent leaks.

Increased Energy Use: The friction and vibration caused by misalignment force the motor to work harder, wasting energy.

A well-chosen coupling dampens these forces, leading to smoother, more reliable, and more efficient operation.

Couplings fall into two main categories: flexible and rigid. For end suction pumps, one is clearly preferred.

Flexible couplings are the go-to choice for nearly all end suction pump applications because they are designed to tolerate small amounts of misalignment and dampen vibration.

This is one of the most common types. It uses a star-shaped elastomer element, often called a [spider,] sandwiched between two metal hubs.

Benefits: Excellent at absorbing shock loads and vibration. They are easy to install, require no lubrication, and are relatively inexpensive.

Typical Uses: HVAC pumps, general water supply, and light industrial applications.

This design uses rubber or polyurethane bushings fitted over pins on one hub, which engage with holes on the other hub.

Benefits: Offers good vibration isolation and can handle moderate torque. It is a simple and robust design.

Typical Uses: Industrial water pumps and cooling systems.

This heavy-duty coupling features a steel grid spring that weaves through grooves in the hubs.

Benefits: Handles high torque and can accommodate more misalignment than other types. The spring design provides excellent torsional flexibility.

Typical Uses: Demanding industrial and process pumps.

Rigid couplings, like sleeve or flange types, create a direct, solid connection between shafts. They do not allow for any misalignment.

Benefits: High torque transmission capacity.

When to Use: They are only suitable when shaft alignment can be maintained with extreme precision, such as in short, highly rigid systems with no thermal expansion.

For the vast majority of end suction pump installations, rigid couplings are not recommended. The real-world operating conditions of commercial and industrial systems demand the forgiveness that a flexible coupling provides.

Proper alignment is crucial for coupling and pump health. Most alignment issues are a combination of three types of misalignment:

Angular Misalignment: The shafts meet at an angle instead of being perfectly parallel.

Parallel (Offset) Misalignment: The shafts are parallel but their centerlines are offset.

Axial Misalignment: The gap between the shaft ends is too large or too small, often due to thermal expansion.

If your pump system shows any of these symptoms, poor coupling alignment is a likely cause:

Excessive vibration, especially near the pump or motor bearings.

Abnormal noise, like humming or whining.

High bearing temperatures (hot to the touch).

Frequent mechanical seal leakage.

Loose coupling bolts or failed elastomer elements.

Higher-than-expected power consumption.

Alignment should be treated as a precision task, not a rough approximation.

During initial installation, you can use a straight edge across the top and sides of the coupling hubs and a feeler gauge to check the gap. This method is only suitable for getting the pump and motor into position before starting precision alignment.

For reliable operation, one of the following methods is necessary.

This traditional method uses dial indicators to measure angular and offset misalignment with high accuracy. It requires a skilled technician but delivers reliable results.

This is the modern standard for critical pumps. Laser systems are extremely fast, highly precise, and provide digital readouts that guide the technician through corrections. They are ideal for ensuring the best possible end suction pump coupling alignment.

Pro Tip: Always perform the final alignment check after all piping is connected and tightened. Pipe strain can easily pull a perfectly aligned pump out of alignment.

A misaligned pump is an inefficient pump. The added friction and vibration require the motor to draw more current to achieve the desired flow and pressure. This internal resistance leads to:

Higher energy losses in the bearings.

Increased motor current draw.

Reduced overall hydraulic efficiency.

Even a small alignment error can cause a measurable increase in energy waste. In systems that run continuously, like cooling water circulation pumps, this wasted energy adds up to significant operational costs over time.

Preventive maintenance can help you catch coupling issues before they cause a catastrophic failure.

Visual Inspection: Regularly check the coupling for signs of wear, especially on elastomer elements, which can crack or deform over time.

Check Fasteners: Ensure hub set screws and bolts are tight.

Monitor Trends: Track vibration levels and bearing temperatures. A sudden increase is a clear warning sign.

Verify Alignment: Re-check alignment periodically, especially after any major maintenance on the pump, motor, or piping.

Replace Worn Parts: Don't wait for a flexible element to disintegrate. Replace it according to the manufacturer's recommended service intervals.

In any end suction pump system, the coupling is far more than just a simple connector. It is a vital component that directly influences the reliability, efficiency, and longevity of the entire pump assembly.

By selecting the right type of flexible coupling, insisting on precision alignment, and performing routine inspections, you can dramatically reduce vibration, extend bearing and seal life, improve energy efficiency, and prevent unexpected downtime. For any facility that relies on pumps, a properly managed coupling is a cornerstone of long-term operational success.

Address

No.17 XeDa Jimei Ind. Park, Xiqing Economic Development Area, Tianjin, China

Telephone

+86 13816508465

QUICK LINKS