+86 13816508465

Pump Knowledge

Oct. 20, 2025

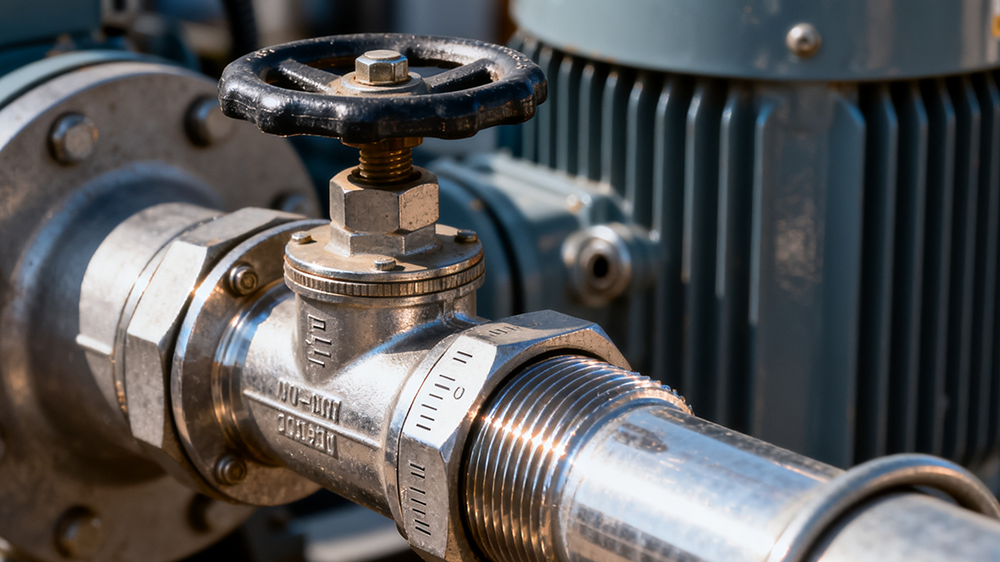

Proper pump valve adjustment is essential for achieving optimal system performance, efficiency, and longevity. The delicate balance between flow rate and pressure dictates how well a pump operates within its design parameters. Incorrect adjustments can lead to a host of problems, including destructive cavitation, low efficiency, and unnecessary stress on the entire system. Mastering this balance is key to running a reliable and cost-effective operation.

This guide provides a comprehensive overview of how to manage the relationship between flow and pressure. We will explore the role of different valves, offer a step-by-step process for making adjustments, and highlight common mistakes to avoid. By the end, you will have the knowledge needed to fine-tune your pumping system for peak performance.

Before adjusting any valves, it's crucial to understand the two primary variables you are controlling: flow and pressure. They have a distinct and interconnected relationship that defines your pump's operation.

Flow Rate (Q): This is the volume of fluid that moves through the pump and piping system over a specific period. It is typically measured in gallons per minute (GPM) or cubic meters per hour (m³/h). Flow rate determines how much work is getting done—for example, how quickly a tank is filled.

Pressure (H): Often referred to as [head,] pressure is the force required to move the fluid against the resistance in the system. This resistance comes from friction in the pipes, changes in elevation (static head), and components like valves and fittings. Pressure is measured in pounds per square inch (PSI) or feet of head.

In most centrifugal pump systems, flow and pressure share an inverse relationship. When you close a valve on the discharge side of the pump, you increase system resistance. This causes the pressure to rise, but the flow rate decreases. Conversely, opening the valve reduces resistance, allowing the flow rate to increase while the pressure drops.

This relationship is visualized using a pump performance curve. This curve, provided by the manufacturer, shows the flow and pressure combinations a pump can deliver. To find the actual operating point, you must overlay it with the system curve, which plots the pressure required to produce a given flow rate in your specific piping network. The intersection of these two curves is the Best Efficiency Point (BEP), where the pump operates most efficiently.

Valves are the primary tools for pump valve adjustment, but not all valves are created equal. Using the right type of valve for the right application is critical for effective control.

Gate Valves: These are designed for on/off service. They create minimal pressure drop when fully open but are not suitable for throttling (partially opening or closing) because the high fluid velocity can erode the gate and seats.

Ball Valves: Like gate valves, ball valves are best for on/off applications. They offer quick shutoff and low resistance but provide poor flow control when used for throttling.

Butterfly Valves: These valves are often used for both throttling and on/off service. They are lightweight and fast-acting, but they create more pressure drop than gate or ball valves when fully open.

Globe Valves: Globe valves are specifically designed for throttling and precise flow regulation. Their internal design allows for fine-tuned control over the flow rate, though they introduce a higher pressure drop than other valve types.

Crucially, flow regulation should always be done using a valve on the discharge side of the pump. Throttling a suction valve starves the pump of fluid, drastically lowering the Net Positive Suction Head (NPSH) and creating a high risk of damaging cavitation.

Achieving the perfect balance requires a methodical approach. Follow these steps for safe and effective pump valve adjustment.

1. Start Safely: Begin the process with the discharge valve partially closed (e.g., 25% open). This prevents the pump from running at the end of its curve (runout), which can overload the motor and cause excessive vibration.

2. Monitor Your Gauges: With the pump running, closely watch the pressure gauges and flow meters. These instruments are your eyes into the system's performance.

3. Make Gradual Adjustments: Slowly open or close the discharge valve to move toward your desired operating point. Make small changes and allow the system to stabilize before making another adjustment.

4. Compare to the Pump Curve: Cross-reference your flow and pressure readings with the pump performance curve. Your goal is to operate as close to the Best Efficiency Point (BEP) as possible to maximize efficiency and minimize wear.

5. Check for Cavitation: Listen for rattling or gravel-like noises, which indicate cavitation. Ensure the available NPSH (NPSHa) in your system is well above the required NPSH (NPSHr) specified on the pump curve. Preventing cavitation is non-negotiable for pump health.

6. Lock in the Position: Once the system is running steadily at the desired flow and pressure, lock the valve handle in place to prevent accidental adjustments.

Precise control is impossible without accurate measurements. The right tools are essential for balancing flow and pressure effectively.

Pressure Gauges and Flow Meters: These are the most fundamental tools. Install calibrated pressure gauges on both the suction and discharge sides of the pump. A reliable flow meter provides real-time data on the flow rate.

Variable Frequency Drives (VFDs): A VFD controls the pump's motor speed, which is a highly efficient way to adjust flow and pressure without throttling a valve. Combining VFD control with minor valve adjustments offers the best of both worlds in terms of energy savings and precise control.

Balancing Valves: In complex systems like HVAC networks with multiple branches, specialized balancing valves allow for fine-tuning the flow to each part of the system, ensuring equitable distribution.

Improper valve adjustment can cause more harm than good. Be aware of these common pitfalls.

Over-Throttling the Discharge Valve: While throttling is necessary for control, closing the valve too much creates excessive pressure, wastes energy, and accelerates wear on the pump and valve. This is like driving a car with the brakes partially engaged.

Throttling the Suction Valve: This is the most dangerous mistake. Adjusting a suction valve to control flow starves the pump, causing severe cavitation that can destroy an impeller in minutes. Never throttle the suction valve.

Ignoring System Leaks or Air Pockets: Air in the system or leaks can give false readings on gauges, leading to incorrect adjustments. Always ensure your system is properly bled and sealed.

Forgetting to Recalibrate: After any system modification or major maintenance, the system curve may change. You must re-evaluate and readjust your operating point to match the new conditions.

Integrate these best practices into your maintenance routine to ensure long-term reliability.

Regularly Review Performance: Periodically compare your pump's actual performance against its pump performance curve to spot inefficiencies or developing problems early.

Combine VFDs and Valves: Use VFDs for primary flow control and use valves for fine-tuning or system balancing. This combination offers the most energy-efficient solution.

Train Your Team: Ensure all operators understand the correct procedures for pump valve adjustment and the dangers of improper techniques.

Keep Detailed Records: Log valve positions, flow rates, and pressure readings. This data is invaluable for troubleshooting and analyzing performance trends over time.

Balancing flow and pressure through careful valve adjustment is not just a technical task—it is a cornerstone of efficient and reliable pump operation. By understanding the interplay between these forces, using the right tools, and following a methodical process, you can position your pump to run at its Best Efficiency Point. This minimizes energy consumption, reduces wear and tear, and is key to preventing cavitation.

Ultimately, a proactive approach that includes regular monitoring, preventive maintenance, and data-driven adjustments will extend the life of your equipment and prevent costly, unexpected downtime.

Address

No.17 XeDa Jimei Ind. Park, Xiqing Economic Development Area, Tianjin, China

Telephone

+86 13816508465

QUICK LINKS