+86 13816508465

Pump Knowledge

Nov. 17, 2025

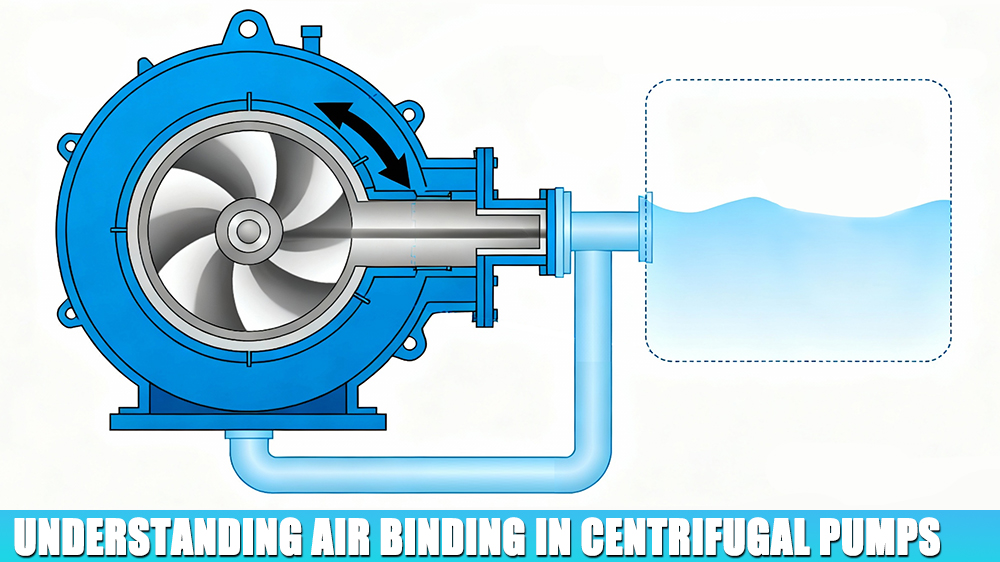

A centrifugal pump is the heart of many fluid transfer systems, but when air gets trapped inside, it can lead to a serious condition known as air binding. This common issue can drastically reduce performance, cause operational failures, and even lead to significant equipment damage. For maintenance professionals and engineers, understanding centrifugal pump air binding is key to ensuring system reliability and efficiency.

This article will explore what air binding is, its primary causes, and the signs to watch for. We will also provide practical air binding solutions to help you prevent and resolve this critical problem, keeping your operations running smoothly.

Air binding occurs when air or other gases get trapped in the pump casing, specifically around the impeller eye. A centrifugal pump is designed to move liquid, not gas. When a significant volume of air accumulates, it creates an air pocket that breaks the continuous flow of liquid.

The pump's impeller spins within this air pocket without being able to [grip] the fluid and impart energy to it. As a result, the pump loses its prime and stops pumping liquid, even though the motor is still running. This situation is not just inefficient; it can quickly lead to overheating and mechanical damage.

The consequences of air binding range from minor inefficiencies to catastrophic failure. Recognizing its impact is the first step in effective pump troubleshooting.

Complete Loss of Flow: The most immediate effect is a total stop in fluid discharge. The pump runs, but no liquid moves through the system.

Reduced Pumping Capacity: Before a complete stoppage, you may notice a significant drop in flow rate and discharge pressure. The pump struggles to perform its duty because the entrapped air disrupts hydraulic action.

Overheating: The liquid flowing through a pump also serves as a coolant. When air binding stops the flow, this cooling effect is lost. The energy from the spinning impeller turns into heat, which can damage seals, bearings, and other internal components.

Cavitation-like Damage: While different from true cavitation (which involves vapor bubbles imploding), the erratic pressures and forces caused by air binding can lead to similar pitting and damage on the impeller and casing.

Vibration and Noise: A pump experiencing air binding will often run with excessive noise and vibration as the impeller spins freely in the air pocket.

To prevent air binding, you must first identify how air is entering the system. The source is almost always on the suction side of the pump, where pressure can be at or below atmospheric pressure.

1. Leaks in the Suction Piping

The most frequent cause of air binding is air leaking into the suction line. Because the pressure inside the suction line is often negative (a vacuum), any small crack, loose fitting, or failed gasket will pull air into the system rather than leak water out.

Common leak points include:

Flange gaskets

Pipe threads

Valve stems and bonnets

Cracks in the suction pipe itself

2. Low Liquid Levels in the Suction Tank

If the liquid level in the supply tank or sump drops too low, a vortex can form on the surface. This whirlpool effect can draw air directly into the suction pipe inlet. Similarly, if the end of the suction pipe becomes uncovered, it will draw in large amounts of air.

3. Dissolved Air in the Fluid

Many liquids contain dissolved gases that can come out of solution when pressure drops. As the fluid enters the low-pressure zone at the impeller eye, these dissolved gases can form bubbles. If enough gas comes out of solution, it can accumulate and cause air binding. This is more common in applications where the liquid is near its boiling point or has been agitated.

4. Improper Priming or Startup

For a centrifugal pump to work, its casing must be completely filled with liquid before it starts. If there is air in the casing during startup, the pump will not be able to create the necessary pressure differential to begin pumping. This is a common issue in systems that are not self-priming.

Resolving air binding involves both fixing the immediate problem and implementing preventative measures. Here are effective solutions to keep your pumps free of air.

1. Perform a Thorough Inspection of Suction Lines

The first step in pump troubleshooting is to meticulously check the entire suction line for leaks.

Visual Inspection: Look for signs of corrosion or damage on pipes, flanges, and fittings.

Pressure/Vacuum Testing: Isolate the suction line and pressurize it with air or a test fluid to identify leaks. A shaving cream or soap solution can be applied to joints to spot bubbling.

Tighten Connections: Ensure all bolts on flanges are tightened to the correct torque and that all threaded connections are sealed properly with pipe dope or PTFE tape.

2. Ensure Proper Suction Inlet Submergence

Prevent vortexing and air intake by maintaining an adequate liquid level above the suction pipe inlet. A general rule is to ensure the submergence depth is at least three times the diameter of the suction pipe. If vortexing is a persistent issue, consider installing a vortex breaker over the inlet.

3. Install Air Release Valves

For systems prone to accumulating air, installing an automatic air release valve at the highest point of the pump casing or the discharge piping can be highly effective. This valve automatically vents trapped air when the pump is running and allows air to enter when the pump is shut down, which can aid in draining the system if needed.

4. Implement Correct Priming Procedures

Ensure operators follow strict priming procedures. The pump casing must be completely filled with liquid before startup.

Manual Priming: Use a funnel or a dedicated priming line to fill the casing until liquid overflows.

Self-Priming Pumps: In applications where the pump is located above the liquid source, using a self-priming centrifugal pump can eliminate priming issues altogether.

Foot Valves: Installing a foot valve at the end of the suction line helps keep the line full of liquid when the pump is off, preventing the need to re-prime at every startup.

Air binding is a preventable problem that can have severe consequences for your centrifugal pumps. By understanding its causes—from suction line leaks to inadequate liquid levels—you can take targeted action. Regular inspections, proper operational procedures, and simple modifications like installing air release valves are all effective air binding solutions.

Proactive maintenance and diligent pump troubleshooting are the best defenses against air binding. By keeping air out of your system, you protect your equipment from damage, ensure reliable performance, and maintain the efficiency of your entire fluid-handling operation.

Address

No.17 XeDa Jimei Ind. Park, Xiqing Economic Development Area, Tianjin, China

Telephone

+86 13816508465

QUICK LINKS