+86 13816508465

Jun. 21, 2025

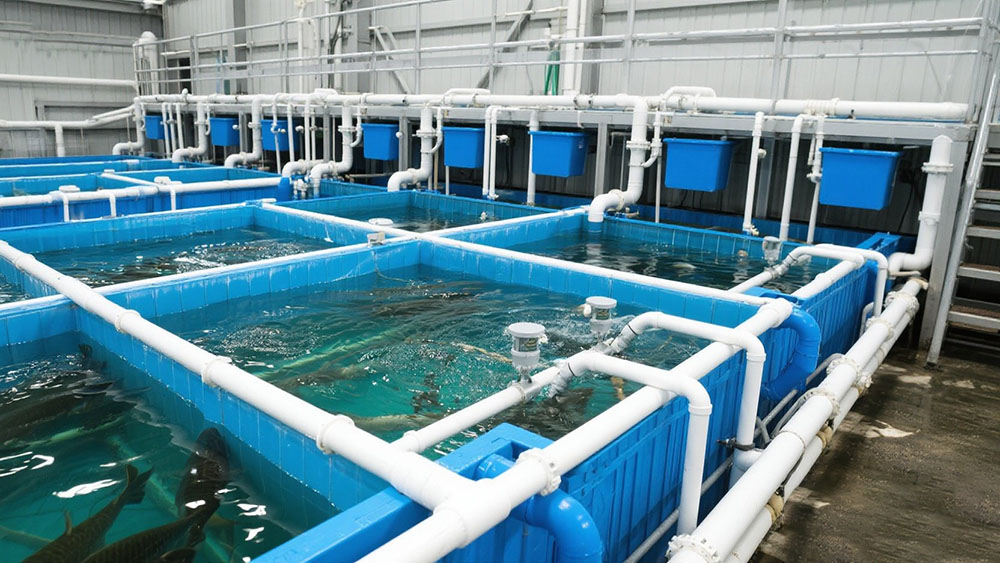

The aquaculture industry is expanding rapidly, driven by the increasing global demand for sustainable seafood and aquatic products. However, with this growth comes the need for cutting-edge systems to ensure optimal water quality and operational efficiency in aquaculture environments. For Recirculating Aquaculture Systems (RAS), one of the most critical components is an effective and robust aquaculture pump system.

Pumps play a vital role in key functions like water circulation, oxygenation, filtration, and waste removal, each of which directly impacts the health and survival of aquatic life. This guide explores optimized pump solutions for aquaculture, covering everything from water intake to chemical dosing, and highlights how proactive pump planning can significantly improve system performance and fish health.

Water Circulation and Filtration

Efficient water circulation is at the heart of any RAS. It ensures that water is continuously moving through filters and biofilters, allowing waste to be removed while maintaining the correct water parameters. The right pump selection is crucial to achieving this.

Centrifugal Pumps in Aquaculture

Centrifugal pumps, especially horizontal end-suction pumps, are widely used for maintaining continuous water flow in aquaculture systems. Their design allows for high flow rates while maintaining energy efficiency, essential for large-scale operations where every watt counts.

Why Low Noise and Vibration Matter

Aquatic environments are sensitive, and excessive noise or vibration can stress fish, leading to poor health or reduced growth rates. Choosing pumps designed for low-noise and low-vibration operation ensures a quiet and stable environment for aquatic species.

When selecting a recirculating aquaculture pump, ensure it meets both your energy efficiency goals and the operational needs of your specific aquaculture setup.

Oxygenation and Aeration

Oxygenation is vital for maintaining healthy fish and aquatic ecosystems. Oxygen depletion is one of the leading causes of fish mortality, making oxygenation systems a top priority for any aquaculture facility.

Advanced Oxygen Mixing Using Pumps

Booster pumps and multistage vertical pumps are often employed to facilitate effective oxygen mixing within water. These pumps can integrate seamlessly with venturi systems to ensure dissolved oxygen levels remain optimal.

Resisting Biofouling for Continuous Operation

Pumps used for oxygenation must withstand biofouling, a common issue in aquaculture due to algae and organic buildup. High-quality oxygenation pumps should support 24/7 operation and require minimal maintenance to prevent interruptions.

An oxygenation pump for fish farms not only sustains aquatic life but also improves feed conversion rates, making it a critical investment for long-term farm profitability.

Solids Removal and Wastewater Transfer

Aquaculture operations generate significant organic waste, including uneaten feed, feces, and suspended sludge. A robust sludge removal pump system is essential for effective solids management.

Submersible Sewage Pumps for Aquaculture

Submersible sewage pumps are the ideal solution for removing waste from tank bottoms. These pumps are capable of handling solids without clogging, ensuring uninterrupted operations.

Integrating with Filtration Systems

Sludge removal pumps often work alongside biofilters or mechanical filters to process and treat wastewater. A carefully integrated system can significantly improve water quality and reduce the risk of ammonia buildup.

Proper waste management not only maintains water quality but also reduces the environmental footprint of aquaculture facilities.

Water Intake and Make-Up Water Supply

Water intake systems are responsible for bringing fresh or treated water into the RAS. This process often involves submersible well pumps designed for high efficiency and durability.

Anti-Clogging Designs for Consistency

Pumps with intake screening and anti-clogging features are essential for maintaining a smooth and reliable water supply.

Corrosion Resistance for Longevity

For facilities using groundwater or brackish water, stainless steel pumps offer excellent corrosion resistance, improving system reliability.

A well-planned water intake pump system ensures a steady supply of quality water, critical for supporting aquatic life and maintaining optimal system parameters.

Chemical and Salt Dosing Systems

Water chemistry is a delicate balance in aquaculture, requiring precise adjustments for pH, salinity, and mineral content. This is where dosing pump systems play an essential role.

Precision with Metering Pumps

Dosing pumps for aquaculture provide the precise delivery of chemicals like pH balancers, salts, and other water conditioners. These pumps are compatible with auto-dosing controllers for accuracy and convenience.

Real-Time Monitoring with Sensors

Many modern dosing systems integrate with sensors to monitor water parameters in real-time and adjust chemical dosages automatically. This enhances overall water quality and minimizes manual intervention.

An efficient chemical dosing system safeguards water conditions, promoting healthy fish growth and reducing operational risks.

Maintenance, Monitoring, and Automation

While choosing the right pumps is essential, maintaining their performance over time is equally critical. A proactive maintenance and monitoring plan can save aquaculture operators significant downtime and costs.

Redundancy and Standby Pumps

For critical processes like water circulation and oxygenation, incorporating redundant pumps ensures that operations continue uninterrupted, even during unexpected failures.

Advanced Sensors for Real-Time Insights

Sensors for flow, temperature, and water level monitoring provide valuable data to optimize pump performance. Automation systems with remote control and alarm functions further enhance operational efficiency.

24/7 Monitoring and Remote Access

Automation systems allow operators to manage pumps remotely, receive alerts about performance issues, and take corrective actions promptly. This ensures reliability and peace of mind for facility managers.

By incorporating modern automation and monitoring technologies, aquaculture operations can achieve higher uptime and greater overall system efficiency.

Taking a Holistic Approach to Pump Planning

Optimized pumping solutions are the backbone of modern aquaculture and RAS facilities. A holistic approach to pump design—not focusing solely on individual components but the system as a whole—is key to success. By integrating specialized pumps for water circulation, oxygenation, solids removal, and chemical dosing, operators can achieve consistent water quality, improve fish survival rates, and reduce operational costs.

If you're looking to plan or upgrade your aquaculture pump system, consulting with water pump experts is the best way to ensure success. They can help tailor solutions that meet the unique needs of your facility while improving reliability and efficiency.

Address

No.17 XeDa Jimei Ind. Park, Xiqing Economic Development Area, Tianjin, China

Telephone

+86 13816508465

QUICK LINKS