+86 13816508465

Pump Knowledge

Feb. 12, 2026

Mechanical seals are vital components in pumps and other rotating equipment, designed to prevent leaks, contain pressure, and keep contaminants out. When a seal works correctly, it operates efficiently for a long time. However, when it fails prematurely, the consequences can be significant. Unexpected downtime, costly repairs, production losses, and even safety hazards can disrupt your entire operation. Understanding the reasons for early failure is the first step toward preventing it.

This post will explore the common causes of premature mechanical seal failure. We will break down why these issues occur and provide practical tips to extend the life of your seals, saving you time and money.

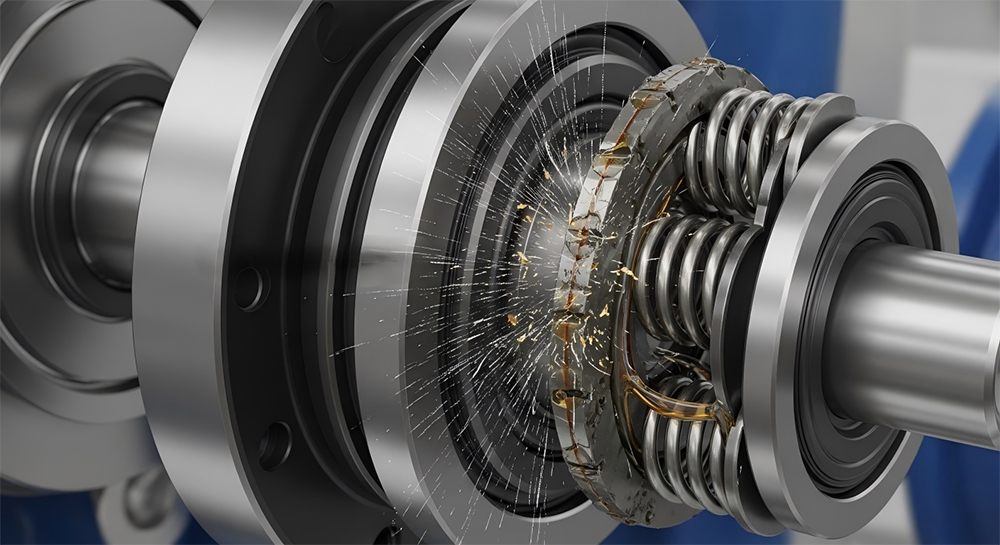

Before diagnosing failures, it's helpful to know how a mechanical seal functions. A standard seal consists of a few key parts: a rotating face that turns with the shaft and a stationary face fixed to the equipment housing. These two highly lapped, super-flat faces are pressed together by a set of springs. A thin film of fluid between these faces acts as a lubricant and a barrier, preventing leaks. O-rings and other secondary seals prevent leakage along the shaft.

For a seal to last, it needs this lubricating film to be stable. Any interruption to this film, whether from heat, pressure, or contamination, can lead to rapid wear and failure.

Most early seal failures are not due to defects in the seal itself but are caused by the operating environment or installation errors. Let's look at the most frequent culprits.

A surprising number of seal failures can be traced back to the installation process. Even the highest-quality seal will fail quickly if it's not installed correctly.

Misalignment: If the seal is not perfectly aligned with the shaft, the faces will not meet evenly. This causes high spots that wear down quickly, leading to leaks.

Incorrect Compression: Seals require a specific amount of compression to work. Too much compression generates excess heat and wears the faces, while too little compression won't create an effective seal.

Contamination: Dirt, dust, or even fingerprints on the seal faces during installation can create a leak path or score the delicate surfaces, causing immediate problems.

Dry running is one of the most destructive things that can happen to a mechanical seal. It occurs when there is no fluid between the seal faces.

Lack of Lubrication: Without the fluid film, the faces grind directly against each other. This creates intense friction and heat, which can cause the faces to crack, warp, or "heat check" in seconds.

Air Entrapment: If air is trapped in the seal chamber, it can displace the process fluid, leaving the seal faces dry.

Startup Procedures: Improper startup, such as failing to vent the pump casing properly, can lead to momentary dry running that inflicts permanent damage.

Heat is a primary enemy of mechanical seals. When temperatures rise beyond the seal's design limits, failure is inevitable.

Inadequate Cooling: Many applications require a flush or cooling plan to remove heat from the seal area. If this system is blocked, inefficient, or improperly designed, the seal will overheat.

High Operating Temperatures: Running equipment outside of its intended temperature range can degrade seal materials, especially elastomers like O-rings, causing them to harden and lose their sealing ability.

Thermal Distortion: Extreme heat can cause the precision-lapped seal faces to distort, breaking the seal and leading to leaks.

The fluid being pumped must be compatible with all materials in the mechanical seal.

Chemical Attack: Aggressive chemicals can corrode metal parts or dissolve the seal faces. This is a common issue in chemical processing and refining industries.

Elastomer Degradation: Elastomers (O-rings, gaskets) can swell, shrink, or harden when exposed to incompatible chemicals. A swollen O-ring can prevent the seal from adjusting to movement, while a hardened one will crack and leak.

A mechanical seal is designed to handle a small amount of shaft movement, but excessive vibration or misalignment will dramatically shorten its life.

Impact of Dynamic Movement: Heavy vibration causes the seal faces to chatter against each other, chipping the edges and allowing leaks.

Bearing Failure Influence: Worn or failing pump bearings allow the shaft to move erratically, which transfers damaging stress directly to the seal. Often, a seal failure is an early indicator of a bearing problem.

Excessive Runout: If the shaft is bent or does not rotate perfectly on its centerline (a condition called "runout"), it will cause the seal faces to open and close with each rotation, leading to rapid wear.

Preventing mechanical seal failure is achievable through a proactive approach focused on proper selection, installation, and maintenance. Implementing these mechanical seal maintenance tips can significantly improve reliability.

The process starts with choosing the right seal for the job. Do not assume a one-size-fits-all approach will work.

Match Seal to Application: Consider the fluid being pumped, its temperature, pressure, and whether it contains abrasive particles.

Chemical Compatibility: Work with your seal supplier to verify that all seal materials, from the faces to the O-rings, are compatible with the process fluid.

Proper installation is non-negotiable for seal longevity.

Follow Manufacturer Guidelines: Every seal comes with specific instructions for a reason. Follow them meticulously.

Use Trained Technicians: Ensure that the personnel installing seals are properly trained and have the right tools. A clean, careful, and precise installation is critical.

Keep a close watch on your equipment to catch problems before they lead to a catastrophic failure.

Vibration Monitoring: Regularly monitor equipment for changes in vibration, which can indicate bearing wear or misalignment.

Temperature Checks: Use a temperature gun to check the seal gland area. A sudden increase in temperature is a clear warning sign of a problem.

Regular Inspections: Look for minor leaks, listen for unusual noises, and check that seal support systems (like flush plans) are operating correctly.

Sometimes, the equipment itself contributes to seal failure.

Improved Cooling and Lubrication: If a seal is consistently overheating, consider upgrading the flush plan or installing a better cooling system.

Filtration Upgrades: If abrasives in the fluid are wearing out seals, install a filter or cyclone separator to provide a clean flush to the seal faces.

Proper Alignment: Use laser alignment tools to ensure precise alignment between the pump and motor shafts during installation.

Premature mechanical seal failure is a costly and disruptive problem, but it is largely preventable. The root cause is rarely a faulty seal but rather an issue with installation, operation, or the system itself.

By focusing on proactive strategies—selecting the right seal, ensuring meticulous installation, performing routine monitoring, and making necessary system improvements—you can move from a reactive "fix-it-when-it-breaks" approach to a reliable, predictive maintenance model. This shift not only extends the life of your mechanical seals but also enhances operational safety, reduces downtime, and delivers significant long-term cost savings.

Address

No.17 XeDa Jimei Ind. Park, Xiqing Economic Development Area, Tianjin, China

Telephone

+86 13816508465

QUICK LINKS