+86 13816508465

Pump Knowledge

Sep. 22, 2025

Selecting the right pump is more than just matching horsepower or pipe size; it's a science that hinges on one critical tool: the pump curve. This graphical chart is the key to ensuring a pump operates efficiently, reliably, and cost-effectively. Whether you're managing water supply, HVAC systems, irrigation, or complex industrial processes, understanding how to read a pump curve is an essential skill. It allows you to move beyond guesswork and make data-driven decisions that prevent premature equipment failure and wasted energy.

This guide will walk you through everything you need to know about pump curves. We'll define what they are, break down their key elements, and show you how to interpret them for practical applications. You will learn how to select the right pump, troubleshoot performance issues, and avoid common mistakes that lead to costly inefficiencies.

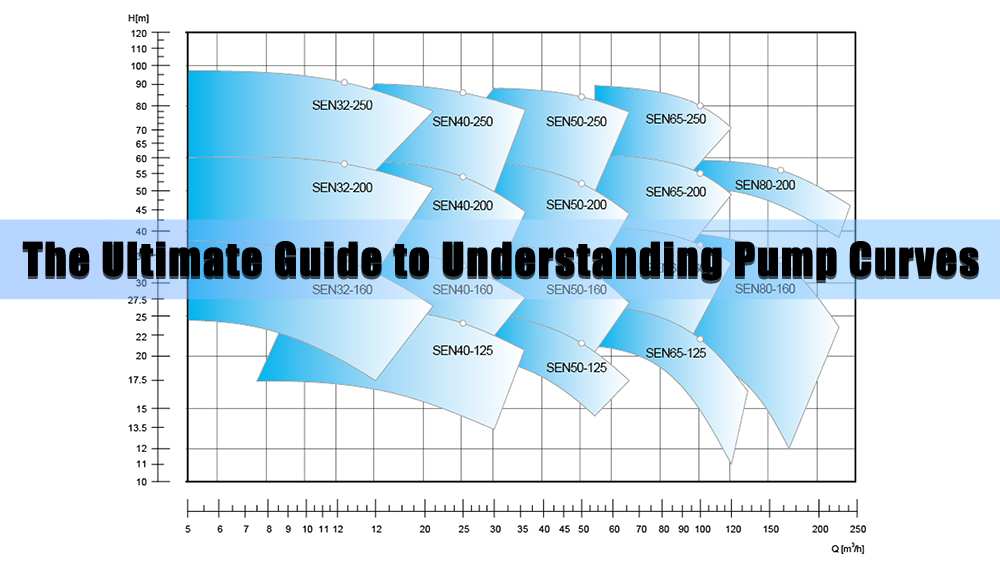

A pump performance curve is a graph that illustrates a pump's capabilities at a specific speed. Generated by the manufacturer during controlled testing, it shows the relationship between the pump's flow rate and the pressure (head) it can produce. In essence, it tells you exactly how a pump will perform under various conditions.

The purpose of a pump curve is to match a pump to the specific requirements of a system. Every piping system has its own 【system curve,】 which represents the head required to move liquid through it at different flow rates. The intersection of the pump curve and the system curve determines the operating point—the actual flow and head where the pump will run. A proper match ensures the pump operates near its most efficient point, saving energy and reducing wear.

A standard pump curve chart contains several lines, each representing a different performance metric. Understanding them is crucial for a complete analysis.

Flow Rate (Q) and Head (H) Relationship

This is the main curve on the chart. The horizontal axis represents the flow rate (Q), typically measured in gallons per minute (GPM) or cubic meters per hour (m³/h). The vertical axis shows the head (H), which is the height to which the pump can lift the fluid, measured in feet or meters. This curve generally slopes downward from left to right, showing that as the flow rate increases, the head the pump can generate decreases.

Best Efficiency Point (BEP)

The Best Efficiency Point (BEP) is the point on the performance curve where the pump operates at its highest efficiency. This is the ideal operating range. Running a pump at or near its BEP minimizes energy consumption and reduces stress on components like bearings and seals, leading to a longer service life. Operating too far to the left or right of the BEP causes hydraulic imbalances that can lead to vibration, cavitation, and premature failure.

Efficiency Curve

This curve, often shown as a dashed line, illustrates the pump's efficiency as a percentage across its flow range. It typically starts low, rises to a peak at the BEP, and then drops off again. This curve helps you visualize how much of the energy consumed by the motor is being converted into useful work (moving fluid).

Power Consumption Curve

The power curve shows how much power (in horsepower or kilowatts) the pump requires at different flow rates. It helps in selecting the correct motor size and predicting energy costs. The curve usually rises with the flow rate, confirming that moving more fluid requires more power.

NPSH Curve (Net Positive Suction Head)

The NPSH Required (NPSHr) curve is vital for preventing cavitation—the formation and collapse of vapor bubbles that can severely damage a pump. This curve indicates the minimum pressure required at the pump's suction port to keep the liquid from vaporizing. To avoid cavitation, the Net Positive Suction Head Available (NPSHa) in your system must always be greater than the NPSHr shown on the curve.

Once you understand the elements, you can use the chart to make informed decisions.

1. Match the System Curve with the Pump Curve: First, calculate your system's curve based on pipe friction losses and static head. Plot this curve on the same graph as the pump curve. The point where the two curves intersect is your operating point.

2. Identify the Operating Point: This intersection reveals the actual flow and head you will achieve. Check where this point falls in relation to the BEP. Ideally, it should be within the 【preferred operating range】 (POR), typically defined as 70-120% of the BEP flow.

3. Recognize Underperformance or Oversizing: If the operating point is far to the left of the BEP, the pump is oversized. It will generate excessive pressure, waste energy, and suffer from high radial thrust. If it's far to the right, the pump is undersized and may struggle to meet flow demands while being at risk of cavitation.

4. Consider Variable Speed Drives (VSDs): A VSD changes the pump's speed, which in turn shifts the pump curve. Lowering the speed moves the curve down and to the left, allowing you to adjust the operating point to match changing system demands efficiently. This is far more effective than using a throttle valve, which wastes energy.

Pump curves are not just theoretical tools; they have direct, practical uses in many scenarios.

Selecting the Right Pump: For any application, whether residential water boosting, agricultural irrigation, or an industrial chemical process, the pump curve is the primary tool for selection. It lets you compare different models and sizes to find the one that best matches your system's requirements for flow and head.

Troubleshooting Pump Problems: If a system isn't performing as expected, the pump curve can help diagnose the issue. By measuring the actual flow and pressure, you can plot the current operating point. If it's not where it should be, it could indicate a clog, a leak, impeller wear, or a change in system conditions.

Predicting Energy Costs: Using the power consumption curve, you can determine the energy needed to run the pump at your operating point. This allows for accurate predictions of operational expenses and helps justify investments in more efficient pumps or VSDs.

Comparing Different Pumps: When faced with multiple options, you can overlay their curves to see which one offers better efficiency at your desired operating point. A pump with a slightly higher initial cost but better efficiency can save thousands in energy over its lifespan.

Even with the right data, misinterpretations can lead to poor pump selection and operation.

Choosing by Maximum Flow or Head: Selecting a pump based solely on its maximum listed flow or head is a frequent error. A pump rarely operates at these extremes and will be highly inefficient. The focus should always be on the operating point.

Ignoring NPSH Requirements: Failing to ensure the system's NPSHa exceeds the pump's NPSHr is a direct path to cavitation damage. This is especially critical in systems with suction lifts or hot fluids.

Operating Too Far from BEP: Consistently running a pump far from its BEP significantly increases wear and tear, leading to frequent repairs and a shortened lifespan. It is the single largest cause of pump failure.

Not Accounting for System Changes: Over time, systems change. Pipes corrode, filters clog, and demand may increase. These changes alter the system curve, shifting the operating point. Regular system assessments are needed to ensure the pump remains efficient.

For more complex systems, a deeper understanding of pump dynamics is required.

Multi-Pump Systems: When pumps are operated in parallel, their flow rates add up at the same head. When in series, their heads add up at the same flow rate. Special combined curves are created to analyze the performance of these multi-pump configurations.

Affinity Laws: These laws describe how a pump's performance changes with speed or impeller diameter. They are fundamental for understanding the impact of VSDs or impeller trimming (machining the impeller to a smaller diameter to reduce performance).

Manufacturer-Specific Charts: Always refer to the specific manufacturer's certified performance charts. Generic curves can be misleading. Manufacturers also provide detailed data on materials, temperature limits, and viscosity corrections.

Software Tools: Modern engineering software can simplify pump curve analysis. These tools can automatically calculate system curves, plot operating points, and compare multiple pumps, saving significant time and reducing the chance of error.

Pump curves are the foundation of smart pump selection and reliable system operation. They provide a complete picture of a pump's performance, enabling you to choose the most efficient equipment for your needs, predict energy consumption, and troubleshoot problems effectively. By learning to read and interpret these charts, you transform pump selection from an art into a science.

Looking ahead, the industry is moving toward digital twin models and IoT-based monitoring. These technologies will provide real-time performance data, allowing for dynamic optimization and predictive maintenance. However, the fundamental principles of the pump curve will remain the core of understanding and managing pump performance for years to come.

Address

No.17 XeDa Jimei Ind. Park, Xiqing Economic Development Area, Tianjin, China

Telephone

+86 13816508465

QUICK LINKS