+86 13816508465

Pump Knowledge

Oct. 23, 2025

Every pump has a sweet spot where it performs optimally, balancing flow, pressure, and power consumption. This is known as the Best Efficiency Point (BEP). Operating a pump near its BEP is crucial for maximizing energy efficiency, ensuring long-term reliability, and extending its service life. Straying too far from this point leads to higher costs, increased wear, and potential system failure.

This guide will walk you through what BEP means for pump performance, how to identify and calculate it, and how to apply this knowledge to your real-world systems. You will learn to use pump performance curves and essential formulas to ensure your equipment runs as intended.

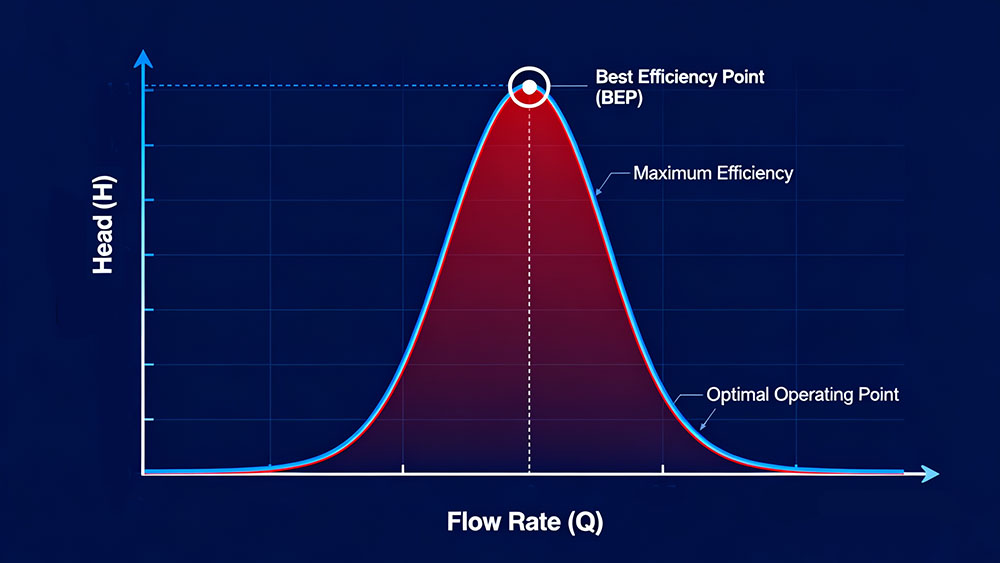

The Best Efficiency Point (BEP) is the point on a pump's performance curve where it achieves its highest hydraulic efficiency. At this specific flow rate and head, the pump converts the maximum amount of input power into fluid movement. It represents the ideal balance between the pump's output and its energy consumption.

BEP is the design point where the impeller's geometry and the casing's hydraulics are perfectly matched. Operating at this point minimizes turbulence, recirculation, and other hydraulic instabilities. This results in the smoothest, most stable operation, which directly translates to less vibration, reduced stress on bearings and seals, and a longer operational lifespan for the pump. The BEP is typically marked directly on a manufacturer's pump performance curve.

Operating a pump far from its BEP can have serious consequences. When a pump runs too far to the left of the BEP (low-flow conditions), it can lead to problems like internal recirculation, increased radial thrust, and higher temperatures. Conversely, running too far to the right (high-flow conditions) can cause cavitation, which erodes the impeller and casing, and creates excessive vibration.

Both scenarios lead to a significant drop in pump efficiency, meaning more energy is wasted as heat and noise, driving up operational costs. These inefficient operating conditions put mechanical stress on the pump's components, including the shaft, bearings, and mechanical seals. The result is more frequent breakdowns, higher maintenance costs, and a shorter overall lifespan for the equipment. Maintaining operation close to the BEP is fundamental to system reliability.

To calculate a pump’s efficiency and find its BEP, you need to understand several key parameters. These measurements form the basis for evaluating pump performance.

Flow Rate (Q): This is the volume of fluid the pump moves over a specific time. It is commonly measured in gallons per minute (GPM) or cubic meters per hour (m³/h).

Total Head (H): Head represents the total energy the pump imparts to the fluid. It is expressed as a height, typically in feet or meters, and accounts for elevation changes, friction losses, and pressure.

Power Input (P): This is the mechanical or electrical power consumed by the pump to move the fluid. It is measured in horsepower (hp) or kilowatts (kW).

Efficiency (η): The ratio of the useful work done by the pump (water horsepower) to the power it consumes (brake horsepower). It is expressed as a percentage.

Pump efficiency (η) is calculated by comparing the fluid power output to the mechanical power input. The formula allows you to determine the efficiency at various operating points to pinpoint the peak value, which is the BEP.

The general formula is:

η (%) = (Q × H × SG) / (3960 × P)

Where:

η is the pump efficiency.

Q is the flow rate in GPM.

H is the total head in feet.

SG is the specific gravity of the fluid (for water, SG is 1).

P is the power input in brake horsepower (bhp).

3960 is a conversion constant.

By calculating the efficiency at several points along the pump's operating range, you can plot an efficiency curve. The highest point on this curve corresponds to the Best Efficiency Point.

The most straightforward method for identifying a pump's BEP is by using the performance curve provided by the manufacturer. This chart graphically displays the pump's capabilities, plotting head, power, and efficiency against the flow rate.

Follow these steps to find the BEP on a pump curve:

1. Locate the Efficiency Curve: Identify the curve on the chart labeled 【Efficiency】 or 【η】. It is typically a parabolic curve that rises to a peak and then falls.

2. Find the Peak: Trace this curve to its highest point. This peak represents the maximum efficiency the pump can achieve.

3. Identify BEP Flow and Head: From the peak of the efficiency curve, draw a vertical line down to the horizontal axis (Flow Rate) and a horizontal line across to the vertical axis (Head). The corresponding values are the flow and head at the Best Efficiency Point.

Interpreting this chart allows you to see how efficiency changes as you move away from the BEP, helping you understand the operational trade-offs.

Besides using manufacturer curves, several other methods can help determine a pump's BEP, especially for existing systems.

Manufacturer Software: Many pump manufacturers offer specialized software that allows you to input your system parameters and select a pump that will operate at or near its BEP.

Field Testing: For pumps already in service, you can conduct field tests using portable instruments. Flow meters, pressure gauges, and power analyzers collect real-time data on flow, head, and power consumption, allowing you to calculate the pump's current operating efficiency.

Computational Fluid Dynamics (CFD): For highly complex or critical systems, CFD analysis can create a digital simulation of the pump and system. This 【digital twin】 allows engineers to model fluid behavior and accurately predict the BEP under various conditions without physical testing.

Knowing your pump's BEP is only half the battle; the goal is to keep it operating there. Proper system design and control are essential for maintaining high efficiency.

System Design: Correctly sizing pipes, selecting appropriate valves, and minimizing bends and fittings reduces system friction (head loss). This helps ensure the system curve intersects the pump curve close to the BEP.

Variable Frequency Drives (VFDs): A VFD is one of the most effective tools for controlling pump operation. It adjusts the pump’s motor speed to match changing system demands, allowing the pump to maintain its BEP across a wider range of flow rates.

Routine Performance Monitoring: Regularly monitoring key metrics like flow, pressure, and power consumption helps detect any deviation from BEP conditions. Data logging and trend analysis can signal issues like wear, clogging, or changes in system demand, enabling proactive maintenance.

Several common errors can lead to inefficient pump operation. Avoiding them is key to a reliable system.

Ignoring System Curve Interaction: The pump's operating point is where the pump curve and system curve intersect. Many engineers focus only on the pump curve, forgetting that changes in the system (like a closing valve) will shift the operating point away from the BEP.

Assuming a Fixed BEP: A pump's BEP can change over time. Impeller wear or trimming the impeller diameter will alter the performance curve and shift the BEP.

Oversizing Pumps: A common mistake is to select a pump that is too large for the application 【just in case.】 This often forces the pump to operate far to the left of its BEP, leading to chronic inefficiency and mechanical problems.

The Best Efficiency Point defines the ideal operating condition for any pump. By understanding, calculating, and designing systems to run at or near the BEP, you can unlock significant benefits. These include lower energy consumption, reduced maintenance costs, less wear on components, and a much longer service life for your equipment.

To ensure your systems are performing optimally, make BEP analysis a standard part of your pump selection and maintenance procedures. Encourage periodic performance testing and data logging to verify that your pumps continue to operate in their sweet spot, delivering reliable performance for years to come.

Address

No.17 XeDa Jimei Ind. Park, Xiqing Economic Development Area, Tianjin, China

Telephone

+86 13816508465

QUICK LINKS