+86 13816508465

Pump Knowledge

Jan. 26, 2026

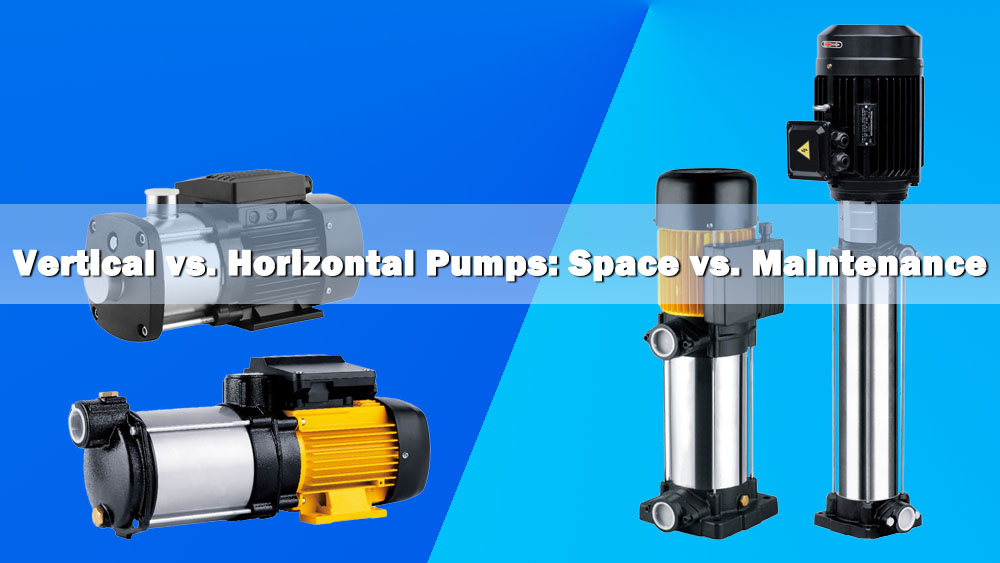

Choosing a centrifugal pump involves more than matching flow and pressure requirements. The physical orientation of the pump—vertical or horizontal—has significant implications for installation footprint, maintenance accessibility, and long-term operational costs. Engineers, facility managers, and contractors often face the choice between these two configurations, and the best decision is not always obvious. This guide is designed to clarify the debate by focusing on the practical trade-offs between footprint, maintenance, and lifecycle cost.This article will provide a detailed comparison of vertical and horizontal centrifugal pumps. We will explore their structures, ideal applications, and the core advantages each orientation offers, helping you make an informed decision based on your specific project constraints.

What Is a Vertical Centrifugal Pump?

A vertical centrifugal pump is defined by its vertical shaft orientation, where the motor is typically mounted above the pump's hydraulic components (the wet end). This design minimizes the amount of floor space the pump occupies.

Basic Structure and Working Principle

In a vertical pump, fluid enters the suction nozzle and is directed into the eye of the impeller. The motor drives the impeller, which rotates and flings the fluid outward by centrifugal force. The fluid then exits through the discharge nozzle, typically at a higher pressure.

Typical Configurations

· Vertical Inline Pump: This is the most common type, where the suction and discharge nozzles are on the same centerline, allowing the pump to be installed directly into a straight run of pipe like a valve.

· Vertical Multistage Pump: These pumps use multiple impellers stacked in series to generate very high pressures, making them ideal for booster applications.

· Vertical Turbine Pump: Used in sumps and wells, these pumps have their hydraulic components submerged in the fluid while the motor remains above ground, connected by a long shaft.

Common Applications

· HVAC systems for chilled and hot water circulation.· Pressure booster systems in high-rise buildings.· Installations in tight mechanical rooms or on compact equipment skids.· Condensate return systems.

What Is a Horizontal Centrifugal Pump?

The horizontal centrifugal pump is the most recognizable and widely used pump configuration in industrial and municipal settings. It features a shaft that is oriented horizontally, with the pump and motor mounted side-by-side on a common baseplate.

Basic Structure and Working Principle

Fluid enters the pump through the end suction nozzle, flows into the impeller, and is discharged radially from the top of the casing. The overhung impeller is supported by a robust bearing frame, which is separated from the motor by a flexible coupling.

Typical Configurations

· End Suction Pump: This is the most prevalent design, conforming to standards like ASME B73.1. It is known for its reliability and serviceability.

· Horizontal Multistage Pump: Similar to its vertical counterpart, this design uses multiple impellers on a single shaft to achieve high pressures, common in boiler feed or reverse osmosis systems.

· Split-Case Centrifugal Pump: The casing is split axially or radially, allowing for easy access to the pump's rotating assembly without disturbing the piping or motor alignment. These are used for high-flow applications.

Common Applications

· Water supply stations and large-scale water transfer.

· Industrial process fluid circulation.

· Irrigation and municipal water projects.

· Fire suppression systems.

Space-Saving Advantages of Vertical Pumps

The most compelling reason to select a vertical pump is its ability to solve space-related challenges.

Smaller Footprint

By stacking the motor on top of the pump, the vertical design dramatically reduces floor space requirements. In a crowded mechanical room where every square foot matters, this compact layout can be the difference between a feasible installation and a complete redesign. It is an ideal solution for retrofitting projects where new equipment must fit into an existing, limited space.

Easier Piping in Tight Spaces

Vertical inline pumps simplify piping layouts. Since their suction and discharge flanges are on the same axis, they can be mounted directly into a pipeline. This eliminates the need for the elbows and complex pipe routing often required to connect a horizontal pump, saving both space and installation costs associated with extra fittings.

Maintenance Advantages of Horizontal Pumps

While vertical pumps save space, horizontal pumps win when it comes to ease of maintenance and serviceability.

Easy Access to Key Components

The design of a horizontal pump lays all major components out for easy access. Bearings, mechanical seals, couplings, and even the impeller can be inspected, serviced, or replaced without having to lift a heavy motor. This straightforward access is a major benefit for maintenance technicians.

Lower Maintenance Labor Cost

Because components are easier to reach, repairs and routine servicing are completed faster. This translates directly to shorter downtime and reduced labor costs. The structure is familiar to most technicians, minimizing the learning curve and potential for errors during maintenance activities.

Better for Heavy-Duty and Long-Term Operation

Horizontal pumps typically feature more robust shaft and bearing arrangements designed for continuous, heavy-duty operation. The separate bearing housing provides superior support against radial loads, contributing to a longer service life in demanding, high-flow applications.

Installation and Alignment Considerations

Vertical Pumps

While an inline pump seems simple, proper support and alignment are crucial. The piping must fully support the pump's weight without imposing strain. For larger vertical pumps with separate motors, shaft alignment is still necessary and can be more challenging than with a horizontal unit due to the vertical orientation. Foundation and vibration control must be carefully engineered to prevent operational issues.

Horizontal Pumps

The critical task for horizontal pumps is the alignment between the pump and motor shafts. This requires precise baseplate leveling, shimming, and laser alignment of the flexible coupling. While this process is labor-intensive, it is a well-understood procedure. Re-alignment is also easier to perform after long-term operation or component replacement.

Reliability and Service Life Comparison

Does orientation affect how long a pump will last? The answer often comes down to installation quality and operating conditions.For vertical pumps, the motor bearings support the hydraulic loads, which can lead to increased wear if the pump operates far from its Best Efficiency Point (BEP). Seal life can also be affected by shaft deflection.Horizontal pumps, with their independent and robust bearing frames, are generally considered more durable for heavy, continuous service. However, their reliability is entirely dependent on maintaining proper shaft alignment. Misalignment is a primary cause of premature bearing and seal failure.

Typical Application Scenarios: Which One Should You Choose?

The decision ultimately rests on balancing priorities for your specific project.

Choose a Vertical Centrifugal Pump If:

· Mechanical room floor space is the primary constraint.

· You need an inline piping layout to simplify installation.

· The system is a compact booster solution for a commercial building.

· The application involves relatively clean liquids and moderate operating hours.

Choose a Horizontal Centrifugal Pump If:

· Easy maintenance access and long service life are your top priorities.

· The system operates continuously or handles high flow rates.

· Sufficient floor space is available for the baseplate and service area.

· The maintenance team is skilled in standard pump alignment procedures.

Common Selection Mistakes to Avoid

· Ignoring Maintenance: Choosing a vertical pump solely for its small footprint without considering how difficult it might be to service the motor or seal in its final location.

· Underestimating Service Needs: Specifying a light-duty vertical pump for a demanding, 24/7 industrial process where a robust horizontal pump would provide better long-term reliability.

· Ignoring System Conditions: Failing to account for the true operating conditions, such as pipe strain or fluid properties, which can favor one orientation over the other.

Conclusion

The debate between vertical and horizontal centrifugal pumps is not about which is universally better, but which is better for a specific application.

Vertical pumps excel in space-saving and compact installations.

Their inline design simplifies piping and makes them a go-to solution for crowded mechanical rooms and modern building services.

Horizontal pumps offer unmatched maintenance ease and operational robustness.

They remain the standard for industrial applications where reliability and serviceability are paramount.The final recommendation is to look beyond the initial purchase price or footprint. Make your selection based on a holistic evaluation of site constraints, your team's maintenance capabilities, and the total lifecycle cost of the pump.

Address

No.17 XeDa Jimei Ind. Park, Xiqing Economic Development Area, Tianjin, China

Telephone

+86 13816508465

QUICK LINKS