+86 13816508465

Pump Knowledge

Aug. 18, 2025

Centrifugal pumps are essential components in countless systems, from residential water supplies to complex industrial operations. They are known for their efficiency in moving fluids, but not all centrifugal pumps are created equal. The number of stages in a pump—single or multistage—can significantly affect its capabilities and how it should be applied.

Understanding the role of stages allows you to select the right pump for your specific needs. But what exactly is the difference between single-stage and multistage pumps? This guide explores their distinctions, advantages, limitations, and how to decide which is best for your project.

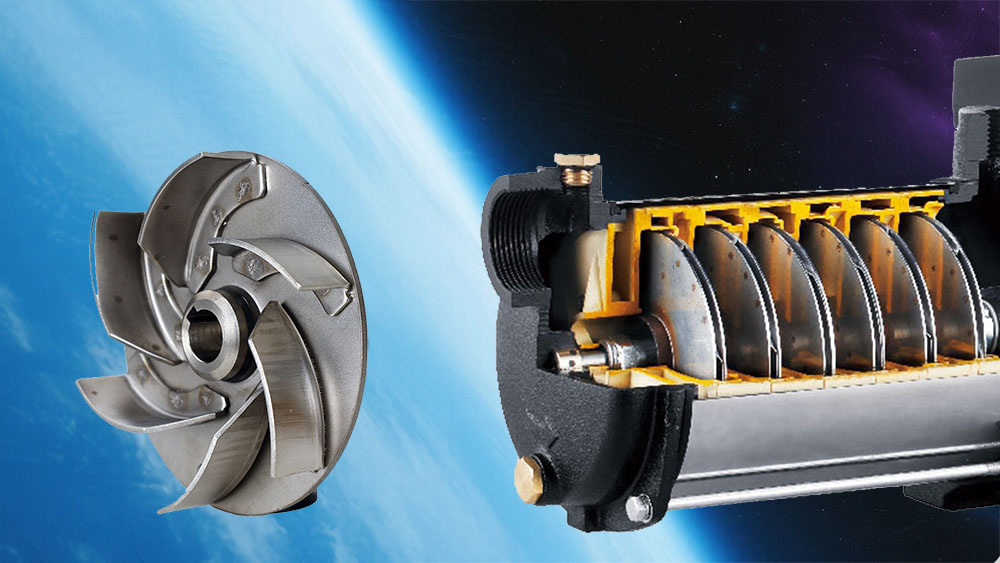

A single-stage pump has only one impeller, the component responsible for transferring energy to the fluid. The working principle is straightforward—fluid enters the pump, gains velocity and pressure energy from the spinning impeller, and exits.

Applications of Single-Stage Pumps

Single-stage pumps are versatile and commonly found in scenarios where low to moderate pressure and high flow rates are needed. Typical uses include:

Irrigation systems for agriculture

Water supply in residential and municipal sectors

HVAC systems to maintain efficient cooling and heating circulation

General industrial processes where fluid transport is required

The simplicity of their design makes single-stage pumps reliable and cost-effective for many standard applications.

Unlike single-stage pumps, multistage pumps contain two or more impellers arranged in series. These impellers work together to increase the pressure of the fluid as it traverses through each stage. This setup makes multistage pumps ideal for applications demanding higher pressures.

Applications of Multistage Pumps

Multistage pumps offer higher adaptability for a wide range of settings, such as:

High-rise buildings to provide consistent water pressure across multiple floors

Boiler feed systems where high-pressure water is required

Reverse osmosis operations in water purification systems

Mining for transferring fluids over long distances and at higher elevations

Their ability to build significant pressure without increasing motor speed makes them energy-efficient and preferable in complex systems.

While both pump types serve the purpose of moving fluids, their functionality, design, and applications differ significantly. Here’s how they compare:

1. Pressure Capability

Single-stage pumps: Generally suitable for low to medium pressure requirements.

Multistage pumps: Capable of achieving substantially higher pressures due to multiple impellers.

2. Flow Rate

Single-stage pumps: Perform better in applications that require high flow rates at lower pressures.

Multistage pumps: Specialize in delivering high head while maintaining moderate flow rates.

3. Design Complexity

Single-stage pumps: Simple and compact with fewer components, making them easier to manufacture and maintain.

Multistage pumps: More intricate due to additional impellers and interconnecting components, which can create challenges during repairs.

4. Maintenance

Single-stage pumps: Require less maintenance because of their straightforward design and fewer parts.

Multistage pumps: Need careful monitoring and expertise during servicing due to their complex assembly.

5. Size and Weight

Single-stage pumps: Generally more compact, making them ideal for installations where space is limited.

Multistage pumps: Tend to be larger and heavier because of the multiple impellers.

Single-stage pumps offer several benefits for specific operating conditions:

A simpler design makes them easy to operate and maintain.

Lower upfront costs, as fewer components result in reduced manufacturing expenses.

Suitable for delivering steady fluid flow in short- to medium-distance applications.

Their reliability and ease of use make them a popular choice for standard pumping needs.

Multistage pumps shine in high-pressure applications where performance and efficiency are paramount:

Achieving high pressures without increasing motor speed minimizes energy consumption.

Their customizable design allows for flexibility—you can add or remove stages depending on pressure needs.

Optimal for long-distance pumping and applications that demand consistent pressure stability.

These qualities make multistage pumps indispensable in industrial and large-scale operations.

While each pump has its strengths, certain limitations must be considered.

Single-Stage Pumps

Limited maximum head makes them unsuitable for high-pressure applications.

Less energy-efficient when operating under high-pressure conditions.

Multistage Pumps

Higher initial and repair costs due to their complex design.

Sensitive to solids—handling abrasive or impure fluids can cause damage.

More intricate maintenance requiring skilled technicians and time.

Making the right choice depends on several factors, including performance requirements and system constraints. Here’s a practical approach:

Assess Head and Flow Requirements:

For low-pressure systems with high flow, a single-stage pump is often sufficient.

For high-pressure demands or long-distance fluid transport, opt for a multistage pump.

Consider Space and Budget:

If space is limited or cost is a priority, single-stage pumps are typically better.

Where higher performance outweighs cost concerns, multistage pumps are more suitable.

Match Pump Type to Operating Conditions:

Analyze the fluid properties, maintenance capabilities, and energy efficiency targets in your specific application to ensure compatibility.

Choosing between a single-stage and multistage pump comes down to understanding your project’s unique needs. A single-stage pump is your go-to option for simplicity, cost-effectiveness, and steady performance in low-pressure scenarios. Meanwhile, a multistage pump shines in high-pressure, demanding environments where energy efficiency and adaptability are critical.

By carefully evaluating your system requirements, you can make an informed decision that ensures optimal performance and cost efficiency over the pump’s lifespan. Whether for a residential building or an industrial setup, there’s a pump solution tailored to fit your needs.

Address

No.17 XeDa Jimei Ind. Park, Xiqing Economic Development Area, Tianjin, China

Telephone

+86 13816508465

QUICK LINKS