+86 13816508465

Pump Knowledge

Sep. 19, 2025

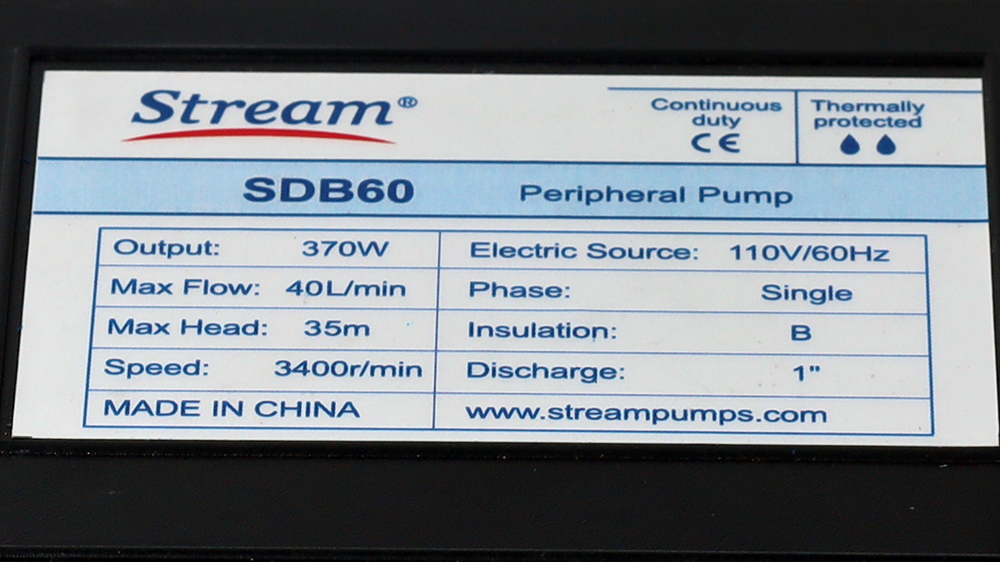

A small metal tag on a pump can be the key to its long-term health and efficiency. This tag, known as the pump nameplate, contains vital information that helps operators, technicians, and engineers make informed decisions. Understanding the data on this plate is crucial for proper pump selection, safe operation, and effective maintenance. It can prevent costly operational errors, reduce downtime, and significantly extend the life of your equipment.

This guide will walk you through everything you need to know about reading a pump nameplate. We will cover where to find it, what key information it holds, and how to interpret its specifications for optimal performance.

A pump nameplate is designed to be a permanent fixture. You can typically find it attached to a non-wearing part of the pump. Common locations include the pump casing (volute), the motor housing, or a dedicated bracket near the inlet or outlet connections.

These plates are built for durability, often made from stainless steel or aluminum. The information is usually engraved or stamped to withstand harsh industrial environments, though some lighter-duty pumps may use a durable sticker. The goal is for the data to remain legible throughout the pump's service life.

While the layout may vary between manufacturers, most nameplates contain a standard set of critical pump specifications. Let's break down the most important sections.

Manufacturer and Model Details

This is your starting point for identifying the pump. Look for:

Brand/Manufacturer: The company that made the pump (e.g., Grundfos, Sulzer, Flowserve).

Model Number: A specific identifier for the pump series and size.

Serial Number: A unique number assigned to that individual pump.

These details are essential for ordering spare parts, claiming a warranty, or contacting technical support. Always have the model and serial number ready when you need assistance.

Hydraulic Performance Data

This section describes the pump's core function: moving liquid. The two most critical values are:

Flow Rate (Q): The volume of liquid the pump can move in a given time. This is often listed in gallons per minute (GPM), cubic meters per hour (m³/h), or liters per second (L/s).

Total Head (H): The height to which the pump can lift the liquid, which is a measure of the pressure it can generate. Head is typically measured in feet (ft) or meters (m).

Some nameplates also list the pump's best efficiency point (BEP), which is the flow rate at which the pump operates most cost-effectively. Operating a pump close to its BEP minimizes energy consumption and wear.

Operating Conditions and Limits

To ensure safety and reliability, a pump must be operated within its design limits. The nameplate specifies these critical parameters:

Maximum Working Pressure: The highest pressure the pump casing can safely withstand. This is usually listed in pounds per square inch (PSI) or bar.

Operating Temperature Range: The minimum and maximum temperatures of the fluid the pump is designed to handle, often in Celsius (°C) or Fahrenheit (°F).

Fluid Type: Some nameplates may indicate limitations on the type of fluid, such as (Water Only) or compatibility with specific chemicals or slurries.

Exceeding these limits can lead to catastrophic failure, posing a significant safety risk to personnel and the surrounding equipment.

Motor and Electrical Data

If the pump is supplied with an integrated motor (a close-coupled unit), the nameplate will also include electrical specifications. This information is vital for connecting the pump to the correct power supply.

Power: The motor's output, rated in horsepower (HP) or kilowatts (kW).

Voltage (V): The required electrical potential.

Phase (Ph): Indicates whether the motor requires single-phase or three-phase power.

Frequency (Hz): The required electrical frequency, typically 50 Hz or 60 Hz depending on the region.

Full Load Amps (FLA): The current the motor will draw when operating at full load. This is important for sizing electrical protection like fuses or breakers.

Speed (RPM): The rotational speed of the motor shaft in revolutions per minute.

Understanding the numbers is only half the battle. You need to apply them to your specific application. For example, the flow rate and head listed on the nameplate usually represent a single performance point, often the BEP. For a full picture of the pump's capabilities, you should consult its performance curve, which is available from the manufacturer.

When connecting the pump, ensure your electrical supply matches the voltage, phase, and frequency listed on the nameplate precisely. A mismatch can damage the motor instantly. Also, pay close attention to units of measurement. Confusing PSI with bar or GPM with m³/h can lead to incorrect pump selection and system design.

Make the pump nameplate a valuable tool in your maintenance and operations toolkit.

1. Record the Data: When a new pump is installed, take a clear photo of the nameplate and store it digitally. This ensures you have the information even if the physical plate becomes damaged or unreadable over time.

2. Verify with Datasheets: The nameplate provides a summary. For detailed information, such as the pump curve, Net Positive Suction Head required (NPSHr), and material compositions, always refer to the official manufacturer datasheet.

3. Streamline Maintenance and Parts Ordering: Use the model and serial number to quickly identify and order the correct spare parts, such as seals, bearings, or impellers. This minimizes downtime and prevents ordering incorrect components.

The pump nameplate is more than just a label; it is a concise instruction manual for the safe and efficient operation of your equipment. By taking the time to read and understand these specifications, you empower yourself to make better decisions regarding installation, operation, and maintenance.

We encourage all operators, technicians, and engineers to familiarize themselves with the nameplates on their equipment. Prioritizing this simple step will lead to more reliable pump performance, increased safety, and a longer service life for your critical assets.

Address

No.17 XeDa Jimei Ind. Park, Xiqing Economic Development Area, Tianjin, China

Telephone

+86 13816508465

QUICK LINKS