+86 13816508465

Jan. 25, 2026

1. Introduction: Beyond the [Seal Quality] Myth

In industrial pump maintenance, mechanical seal leakage accounts for the majority of reported failures. When faced with repetitive seal failure, operators' immediate reaction is often to question the quality of the seal component or the precision of the installation. However, when failures persist even after upgrading to heavy-duty seals, the focus must shift to the underlying mechanical dynamics.In many cases, the mechanical seal is merely the [victim] of system instability, not the root cause. A critical yet often overlooked physical factor driving premature failure is Axial Thrust. Without addressing the hydraulic balance of the rotor, simply replacing the seal component is a temporary fix that fails to address the fundamental mechanical stress.

2. The Physics: Understanding Axial Thrust

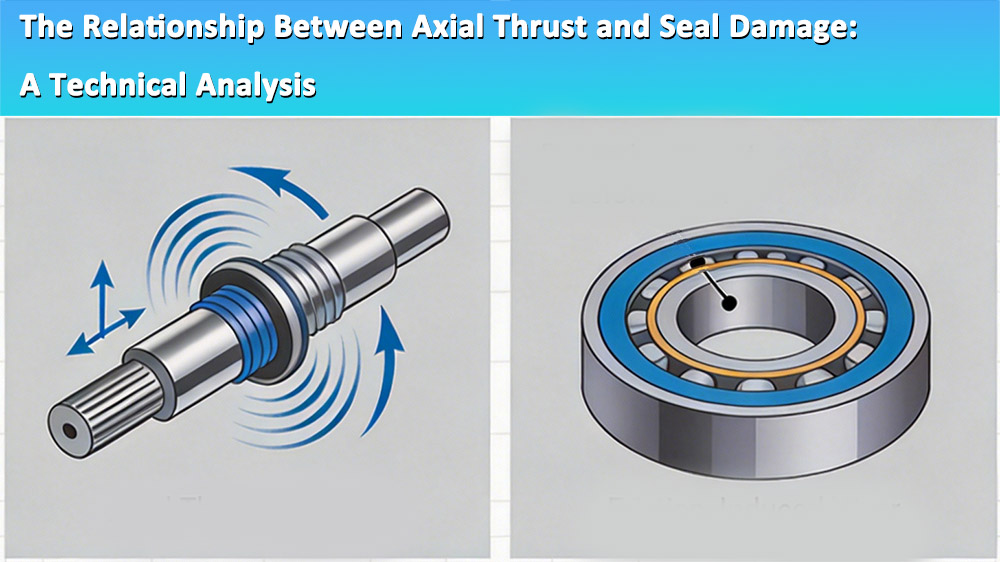

To understand why seals fail, one must first understand the force environment within the pump casing.Axial Thrust is the net force acting on the rotor (shaft and impeller) parallel to the shaft axis. Simply put, it is the hydraulic force attempting to push the shaft either towards the suction eye or towards the motor.This force originates from the pressure differential across the impeller:· Suction Side: The impeller eye operates at low pressure.· Discharge Side: The area behind the impeller shroud is subjected to high discharge pressure.This uneven pressure distribution creates a massive net force acting towards the suction eye. Under normal design conditions, the pump's Thrust Bearing absorbs this load, [anchoring] the shaft in position. However, if operational conditions cause the thrust to exceed the bearing's load capacity, the bearing can fail or deflect, allowing the shaft to physically move within the housing (known as Axial Shuttling).

3. Failure Mechanisms: How Thrust Physically Damages the Seal

Mechanical seals are precision instruments. The mating of the rotating face and the stationary face relies on precise spring compression settings, with installation tolerances often as tight as +/- 0.5mm.When uncontrolled axial thrust forces the shaft to shuttle, it destroys the seal through two specific physical mechanisms:

A. Face Loading (Crushing)

When axial force pushes the shaft excessively towards the suction eye, the rotating face is driven forcefully into the stationary face. This results in:· Dry Running: Extreme contact pressure squeezes out the lubricating fluid film between the faces.· Heat Checking: Friction generates intense heat, causing radial cracks on ceramic or hard-face surfaces.· Disintegration: Under extreme loads, carbon faces may shatter completely.

B. Face Separation (Opening)

In transient conditions (such as water hammer during shutdown or surging), the shaft may shuttle in the opposite direction. This forces the seal faces apart, leading to:· Massive Leakage: Instant release of pressurized fluid.· Debris Ingress: Solid particles enter the gap between the open faces. When the shaft returns to position, these particles act as an abrasive, destroying the polished seal surfaces.

4. Root Cause Analysis: Why Thrust Gets Out of Control

A well-designed pump should balance nominal axial forces. Uncontrolled thrust is usually caused by specific operational issues:· Operating Off-Curve: Pumps are hydraulically balanced at their BEP (Best Efficiency Point). Operating at very low flow (excessive throttling) or very high flow (run-out) disrupts the pressure distribution around the impeller, generating unpredictable and excessive axial loads.· Worn Wear Rings: Wear rings act to isolate high-pressure and low-pressure zones, assisting in balancing back pressure. As these rings wear and the clearance increases, this hydraulic balancing effect is lost, causing the net axial thrust to multiply.· Cavitation: The collapse of cavitation bubbles creates high-frequency shockwaves. This induces violent axial vibration in the shaft, hammering the seal faces thousands of times per minute.

5. Diagnosis & Solution

To confirm if Axial Thrust is the culprit, perform a teardown analysis:Diagnosis Checklist:1. Inspect Old Seals: Deep wear tracks, heat checking, or shattered carbon rings are clear signs of excessive face loading.2. Inspect Bearings: If thrust bearings are also overheating, discolored, or showing cage wear, it confirms excessive axial load.Prevention Strategies:· Operational Control: Ensure the pump operates near its BEP. Avoid using oversized pumps for small flow requirements.· Maintenance: Monitor wear ring clearance regularly. Replacing a wear ring is significantly cheaper than replacing a seal and shaft.· Hydraulic Design: For demanding applications, select pumps with built-in balancing features. Stream Pumps, for example, utilize advanced impellers with Back Vanes or Balance Holes specifically engineered to neutralize axial forces at the source, protecting the seal.

Conclusion

A leaking seal is often a symptom, not the disease. Without addressing shaft movement caused by axial thrust, expensive seal materials are a wasted investment. Reliability is achieved by controlling the operating point, maintaining wear rings, and selecting the correct hydraulic design.If your facility faces frequent seal replacements, contact the Stream Pumps Technical Team. We can assist in analyzing your system conditions and providing anti-thrust pump solutions designed for longevity.

Address

No.17 XeDa Jimei Ind. Park, Xiqing Economic Development Area, Tianjin, China

Telephone

+86 13816508465

QUICK LINKS