+86 13816508465

Pump Knowledge

Nov. 19, 2025

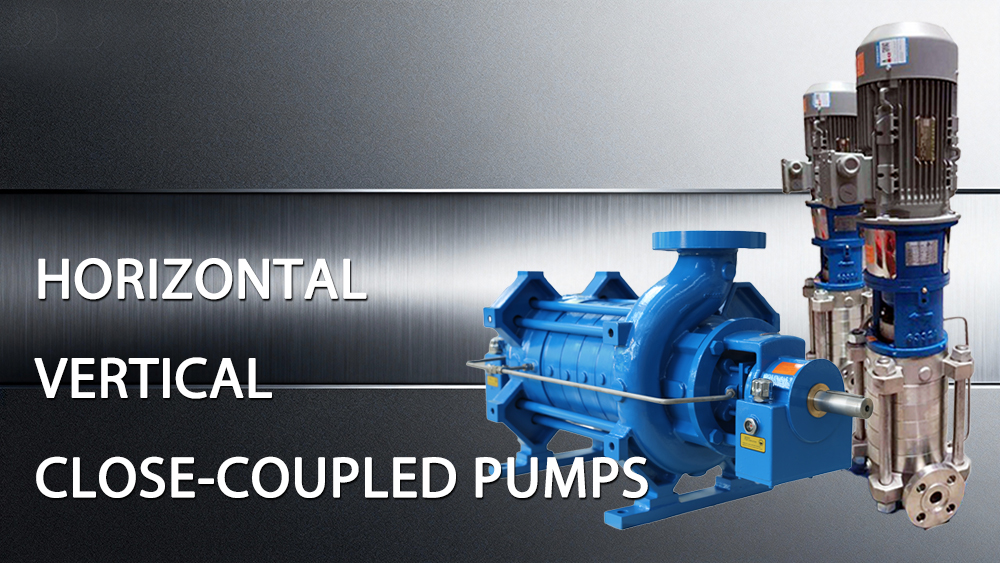

End-suction pumps are a cornerstone of fluid transfer systems across countless industries. Their simple yet effective design makes them one of the most widely used types of centrifugal pumps available today. But not all end-suction pumps are created equal. Understanding the differences between their main configurations—horizontal, vertical, and close-coupled—is key to selecting the right pump for your specific needs.

An end-suction pump is defined by its flow path. Fluid enters the pump through a suction nozzle at one end of the pump casing and is discharged at the top, perpendicular to the suction line. This straightforward design contributes to its popularity, offering reliable performance and ease of use. Let's explore the three common designs to see how they compare.

While all end-suction pumps share a similar operational principle, their physical layout can vary significantly.

Horizontal End-Suction Pump: In this configuration, the pump and motor are mounted side-by-side on a common baseplate. This is a traditional and very common setup.

Vertical End-Suction Pump: This design orients the pump vertically, with the motor positioned directly above the pump. This arrangement is ideal for saving floor space.

Close-Coupled Pump: Here, the pump's impeller is connected directly to the motor shaft, creating a single, compact unit without a separate coupling or baseplate.

The horizontal configuration is often what comes to mind when people think of an industrial pump. Its long-standing presence in the market is due to a combination of reliability and serviceability.

Advantages:

Easy Maintenance: The side-by-side layout provides clear access to the pump, motor, and coupling, making installation, inspection, and repairs straightforward.

Stability: A wide, stable base allows for secure mounting, which is ideal for handling large flow capacities and high-power applications.

Versatility: This common design is available in a vast range of materials and configurations to suit different fluids and operating conditions.

Disadvantages:

Large Footprint: The horizontal arrangement requires a significant amount of floor space compared to other designs.

Alignment Needs: The separate pump and motor require precise alignment of their shafts during installation to prevent premature wear on bearings and seals.

Best Applications:

Industrial water supply and circulation systems

HVAC and fire-fighting networks

Municipal and commercial water transfer stations

Large-scale irrigation projects

When floor space is at a premium, the vertical end-suction pump offers a smart solution. By stacking the motor on top of the pump, it delivers powerful performance within a much smaller footprint.

Advantages:

Space-Saving Design: Its primary benefit is the significant reduction in required floor space, making it perfect for tight mechanical rooms or crowded facilities.

Simple Installation: This design often simplifies piping layouts and can be easier to install in areas with limited horizontal space.

Motor Protection: Mounting the motor above the pump reduces the risk of damage from potential flooding in basements or low-lying areas.

Disadvantages:

Challenging Maintenance: Accessing the pump for maintenance or dismantling can be more difficult due to the vertical layout. It may require lifting equipment to remove the motor.

Increased Bearing Load: The motor bearings must support the weight of the impeller and shaft, which can lead to increased stress.

Best Applications:

Water supply in high-rise buildings and commercial facilities

Cooling tower circulation and condenser water systems

Booster systems where space is limited

Industrial plants with vertical piping arrangements

Close-coupled pumps represent the most compact and simple design. By mounting the impeller directly onto the motor shaft, these pumps eliminate the need for a baseplate and coupling, making them highly integrated and cost-effective.

Advantages:

Compact and Simple: The integrated design is extremely compact, requiring minimal space and simplifying installation.

No Alignment Needed: Since the impeller is directly attached to the motor shaft, there is no need for shaft alignment, reducing installation time and complexity.

Cost-Effective: With fewer components, these pumps are generally less expensive to purchase and easier to replace as a complete unit.

Disadvantages:

Limited Power Range: This design is typically limited to smaller motor sizes and cannot handle the high-pressure and high-flow applications of larger pumps.

Increased Motor Strain: The motor bearings carry all axial and radial loads from the pump, which can shorten the motor's lifespan, especially under demanding conditions.

Temperature and Pressure Limitations: They are less suitable for pumping high-temperature or high-pressure fluids, as heat can transfer directly to the motor bearings.

Best Applications:

Domestic water boosting and residential irrigation

Light commercial use, such as small HVAC systems and circulation loops

Portable pump systems or applications where the pump is integrated into original equipment (OEM).

Choosing the right end-suction pump comes down to balancing your application's requirements for space, performance, and maintenance. This table provides a quick summary of the key differences between the three configurations.

Feature | Horizontal | Vertical | Close-Coupled |

Space Required | Large | Small | Very Small |

Maintenance | Easy | Moderate | Easy (Replacement) |

Efficiency | High | High | Moderate |

Installation Cost | Medium | Medium | Low |

Ideal For | Industrial / Municipal | Buildings / HVAC | Domestic / Light-Duty |

When selecting the right end-suction pump for your project, consider these key factors:

Assess the available space, as some configurations require a larger footprint than others.

Determine the required flow rate and pressure to ensure the pump will meet your system's demands.

Evaluate the ease of maintenance and the accessibility of the installation environment.

For chemical or marine environments, prioritize pumps constructed with corrosion-resistant materials.

If your application involves continuous, 24/7 operation, horizontal pumps generally offer greater durability.

Each pump configuration offers distinct advantages tailored to specific needs. The ideal pump for your application depends on factors like available space, desired flow capacity, and operating conditions. To achieve optimal system performance and longevity, it's best to consult with pump specialists when designing or upgrading your system. By aligning your pump selection with your unique requirements, you'll ensure both efficiency and reliability in any environment.

Address

No.17 XeDa Jimei Ind. Park, Xiqing Economic Development Area, Tianjin, China

Telephone

+86 13816508465

QUICK LINKS