+86 13816508465

Pump Knowledge

Jul. 22, 2025

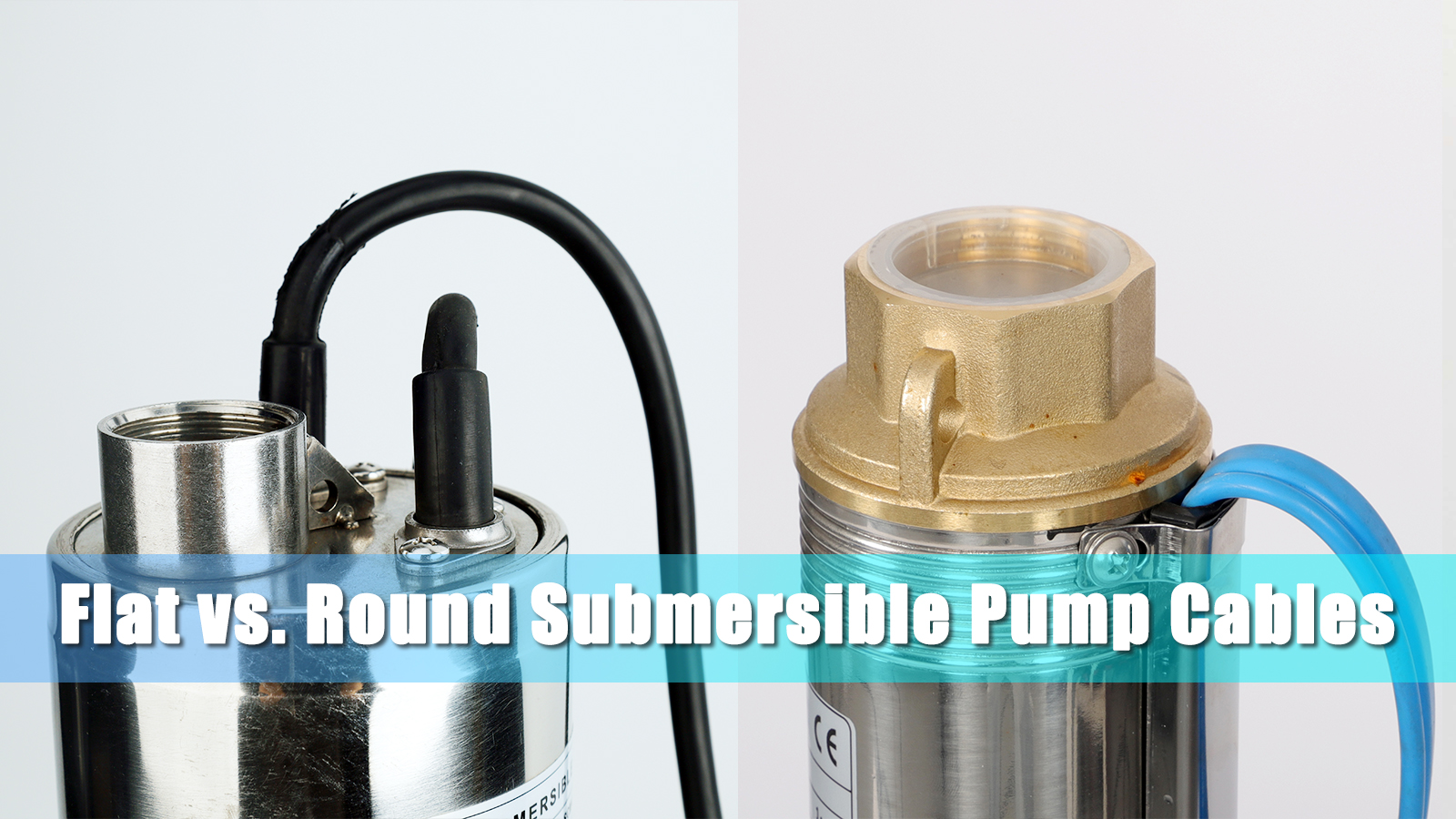

Submersible pumps play a crucial role in water management, particularly in deep well applications. Whether it’s for agricultural irrigation, industrial processes, or residential water supply, these pumps depend on one key component for smooth operation—cables. Selecting the right cable type is critical not only for efficiency but also for long-term safety.

Three commonly used cable structures include flat blue cables, round black cables, and a hybrid approach combining the two. Each has its unique characteristics, advantages, and drawbacks. This post will explore these cable types in detail, compare their pros and cons, and guide you in choosing the right option for your specific application.

1.1 Flat Blue Cable

Flat blue cables are identifiable by their soft, flat structure. They are typically made from flexible materials like PVC or rubber and are often used in short lengths. You'll find these cables most commonly as motor leads or the initial wire segments directly connected to the pump motor.

Shape and Material: Flat, lightweight, and flexible.

Usage: Initial wire connection and shallow well applications.

Insulation: Usually PVC or rubber, available in blue.

Flat cables are easy to install and cost-effective for small or shallow submersible pump systems. However, they may lack the durability and protection required for long-term use in deeper or more challenging environments.

1.2 Round Black Cable

Round black cables are more robust, featuring a thick, cylindrical structure designed for durability and extended performance. These cables can be used for long cable runs, making them ideal for deep wells or installations where additional strength and waterproofing are critical.

Shape and Material: Thick, round, and highly durable.

Usage: Ideal for deep wells and high-power pumps.

Insulation: Fully insulated with protective layers for outdoor and underwater use.

While round black cables excel in strength and waterproofing, they can be more expensive and less flexible during installation compared to their flat counterparts.

1.3 Flat Blue + Round Black Hybrid Structures

The hybrid setup combines the benefits of both flat blue and round black cables. Typically, a short-length flat blue cable connects the motor, while the long external cable extending into the well is a round black cable. This is a common configuration for exported submersible systems or factory-standard motor installations.

Structure: Combines flexibility and durability.

Usage: Standard choice for medium-depth wells and export models.

Consideration:Requires proper waterproof sealing between cable types to ensure reliability and safety.

This hybrid approach balances flexibility and strength, allowing for a cost-effective yet durable cable solution.

The table below summarizes the advantages, disadvantages, and best-use scenarios for each cable type:

Cable Type | Advantages | Disadvantages | Best for |

Flat Blue Cable | Cost-effective, easy to connect, highly flexible | Weaker protection, less abrasion resistance, unsuitable for deep hanging | Small pumps, shallow wells, short cable runs |

Round Black Cable | High strength, superior waterproofing, durable | More expensive, stiff, and harder to handle | Deep wells, high-power pumps, long cable lengths |

Flat Blue + Round Black | Balanced performance and cost, versatile design | Requires careful waterproof sealing at the junction | Medium-depth wells, export-ready installations |

This straightforward comparison can help you identify the most suitable cable structure for your project.

Selecting the right submersible pump cable involves evaluating your specific needs, such as well depth, pump size, and environmental conditions. Here’s a quick guide:

Shallow Wells (<20m):

Either flat blue cables or hybrid setups work well for shallow installations due to shorter cable requirements.

Deep Wells (>30m):

Round black cables are the preferred option. Their durability and waterproofing make them ideal for the high demands of deep wells.

Export or General-Purpose Installations:

The hybrid structure is widely used in general use or factory-exported systems.

Cable Specifications:

Always verify voltage, current capacity, and waterproof ratings to ensure compatibility with your pump setup.

Investing in the right cable type matched to your application can prevent costly repairs and ensure optimal pump performance over time.

Proper installation is just as essential as choosing the right cable. To maximize performance and longevity, follow these tips:

Ensure Waterproof Sealing:

When using a hybrid structure, carefully seal the junction between the flat and round cables to prevent water seepage.

Avoid Abrasion:

Prevent cable wear and damage by minimizing sharp bends. Use spacers or protective sleeves where cables might touch sharp edges in the well casing.

Use Cable Clips:

For deep well installations, attach the cable at regular intervals to prevent unnecessary strain on the motor connection.

Regular Inspection:

Check exposed portions of the cable regularly for signs of wear, aging, or damage. Replace compromised cables immediately to ensure safety and efficiency.

These precautions will help keep your system running smoothly and extend the life of both your pump and its components.

When it comes to submersible pump cables, there’s no one-size-fits-all solution. The type of cable you choose depends on several factors, including the depth of your well, the power rating of your pump, and your budget. Flat blue wires are great for shallow wells and low-cost installations, while round black cables offer the strength and durability needed for deep wells. Hybrid setups, on the other hand, provide a versatile solution for medium-depth applications.

Investing in the right cable ensures not only long-term pump efficiency but also safety and reliability. Make your choice carefully, and don’t overlook installation best practices to secure the system’s performance.

Need help choosing the right submersible pump and cable for your project?

Address

No.17 XeDa Jimei Ind. Park, Xiqing Economic Development Area, Tianjin, China

Telephone

+86 13816508465

QUICK LINKS