+86 13816508465

Pump Knowledge

Jan. 25, 2026

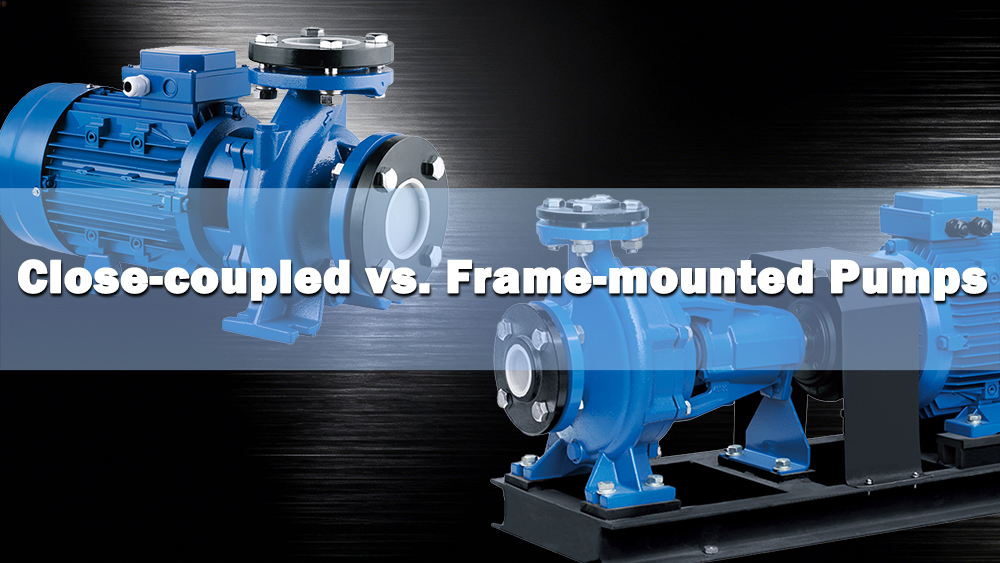

Selecting the right centrifugal pump design is rarely just about flow and head. While the hydraulic performance might look identical on a curve, the mechanical configuration determines the pump's reliability, maintenance cost, and lifespan.The fundamental choice often comes down to two primary configurations: close-coupled versus frame-mounted. The core difference lies in how the pump connects to the motor driver. A close-coupled pump relies on a single shaft—or a rigid extension—connecting the motor and impeller. In contrast, a frame-mounted pump utilizes a flexible coupling to connect two separate shafts, usually housed on a common baseplate.This article provides a detailed engineering analysis of the mechanical pros and cons of each design. We will examine factors like shaft alignment, thermal expansion, and footprint to help you select the correct configuration for your specific application variables.

Understanding Close-Coupled Pumps

Often referred to as a [monoblock] design, the close-coupled pump is a study in efficiency and compactness.

Mechanism

In a close-coupled configuration, the pump impeller mounts directly onto the extended drive shaft of the motor. There is no separate pump shaft or bearing assembly. The motor bearings handle all radial and axial loads generated by the pump. The pump volute (casing) bolts directly to the face of the motor.

Key Advantages

No Alignment Required

This is arguably the most significant operational benefit. Because the motor and pump share a single rigid shaft (or a tightly integrated rigid coupling), misalignment is mechanically impossible. This eliminates the need for laser alignment during installation and periodic maintenance checks, saving significant labor hours.

Compact Design

Space is often at a premium in mechanical rooms or skid packages. Close-coupled pumps have a significantly smaller footprint because they lack a bearing housing and coupling guard. This makes them the preferred choice for OEM machinery integration.

Lower Manufacturing Costs

Fewer parts equal lower costs. These units do not require a heavy structural baseplate, a flexible coupling, or a separate bearing housing. This simplicity translates to a lower initial purchase price compared to frame-mounted equivalents.

Key Disadvantages

Seal Failure Risk

The proximity of the wet end to the motor is a vulnerability. If the mechanical seal fails catastrophically, pressurized fluid can spray directly into the motor front bearing or windings. While flinger rings help, the risk of collateral motor damage is higher here than in other designs.

Thermal Limits

These pumps are generally not suitable for high-temperature fluids. Because the motor shaft is directly connected to the impeller, heat conducts rapidly from the fluid to the motor bearings. This thermal expansion and heat soak can shorten motor life significantly.

Understanding Frame-Mounted Pumps

The frame-mounted pump—also known as long-coupled or base-mounted—is the traditional workhorse for heavy industrial applications.

Mechanism

In this design, the pump and the motor are separate independent units mounted on a common baseplate. The pump has its own shaft and bearing assembly (the power frame). Torque is transmitted from the motor to the pump via a flexible coupling.

Key Advantages

Thermal Isolation

The physical separation between the pump volute and the motor creates a thermal buffer. The air gap, combined with the coupling, prevents heat from the process fluid from conducting into the motor. This makes frame-mounted designs ideal for hot oil, boiler feed, or cryogenic applications.

Component Protection

If a mechanical seal leaks, the fluid drips into the catch basin of the baseplate rather than onto the motor. The motor remains safe, ensuring that a simple seal repair doesn't turn into a costly motor replacement.Motor Flexibility

You are not locked into a specific specialized motor. If the motor fails, you can replace it with any standard NEMA or IEC motor of the correct frame size. You can often change the motor without opening the pump's wet end, provided the coupling spacer is removed.

Key Disadvantages

Alignment is Critical

Misalignment is a leading cause of premature pump failure. Because the pump and motor are separate, they must be precisely aligned. This requires skilled labor and laser alignment tools during initial installation and every time maintenance is performed. Thermal expansion during operation can also throw off alignment if not calculated correctly.

Space & Cost

These units are heavier, longer, and more expensive to install. They require a robust, grouted foundation to dampen vibration and maintain alignment, increasing the total civil engineering cost of the project.

The Comparison Matrix (Technical Breakdown)

To help visualize the differences, we can break down these two configurations across four critical engineering criteria.

1. Shaft Alignment

· Close-Coupled: Zero alignment required. The design relies on machined fits (rabbet fits) to maintain concentricity.

· Frame-Mounted: Requires precise angular and parallel alignment. Ideally, this should be done with laser tools to tolerances of 0.002" or better to prevent coupling and bearing wear.

2. Temperature Handling

· Close-Coupled: Limited. Generally restricted to fluids under 250°F (approx 120°C). Above this, heat creep damages motor grease and insulation.

· Frame-Mounted: Excellent. Can handle extreme heat or cold. With cooled bearing housings and proper metallurgy, these pumps can handle fluids exceeding 600°F (315°C).

3. Vibration & Stability

· Close-Coupled: The overhung load is supported entirely by the motor. While stable for smaller sizes, they are less forgiving of pipe strain.

· Frame-Mounted: Superior stability. When properly grouted, the baseplate absorbs vibration and handles higher pipe loads. The separate bearing housing is designed specifically to handle hydraulic loads that might otherwise fatigue a standard motor shaft.

4. Maintenance Complexity

· Close-Coupled: [Plug and play] operation, but difficult repair. If the shaft surface at the seal area wears down, the entire motor rotor or shaft often needs replacing or machining.

· Frame-Mounted: Modular. If the pump shaft wears, you replace just the pump shaft, not the motor. However, it requires a higher skill tier for alignment and baseplate leveling.

When to Use Which? (Selection Guide)

Engineers must weigh the trade-offs based on the specific system requirements. Use this guide to determine the best fit for your facility.

Select Close-Coupled When:

· Space is a premium: You are designing a compact skid or retrofitting a tight mechanical room.

· Budget is limited: The project demands a lower CAPEX and lower installation costs.

· Moderate Conditions: The application involves clean water, glycol, or mild chemicals at moderate temperatures (below 200°F).

· Maintenance limitations: The on-site maintenance team does not possess laser alignment tools or training

.Select Frame-Mounted When:

· Extreme Temperatures: You are pumping high-temperature fluids (over 250°F / 120°C) where thermal expansion is a major factor.

· Critical Duty: The application is in Oil & Gas or continuous chemical processing where pump reliability is paramount and unscheduled downtime is unacceptable.

· High Horsepower: The application requires large motors (above 50-100 HP) where standard C-face close-coupled motors may not be readily available or cost-effective.

· Heavy Pipe Strain: You expect significant nozzle loads that require the rigidity of a base-mounted unit.

Summary

In the debate of close-coupled vs. frame-mounted pumps, there is no single [better] option—only the correct pump for the specific job.The close-coupled pump is the champion of compactness and simplicity, offering a reliable solution for standard water and mild chemical applications where floor space is scarce. The frame-mounted pump remains the champion of durability and extreme conditions, offering the robustness required for heavy industrial processes and thermal extremes.Before making a purchase, mechanical engineers should look beyond the flow rate. Analyze your system curve, fluid properties, and maintenance capabilities. By matching the mechanical configuration to the operational reality, you ensure long-term system efficiency and reliability.

Address

No.17 XeDa Jimei Ind. Park, Xiqing Economic Development Area, Tianjin, China

Telephone

+86 13816508465

QUICK LINKS