+86 13816508465

Pump Knowledge

Jul. 24, 2025

When it comes to electric pump systems, every component plays a role in ensuring efficient and reliable performance. But few are as pivotal as the bearings. Hidden within the motor, bearings provide the support, alignment, and stability that keep pumps operating smoothly. Yet, when pump systems fail prematurely, poor bearing quality is often the unseen culprit.

As a procurement or maintenance professional, the stakes are high. A substandard bearing might save costs upfront but could lead to expensive downtime and equipment damage later. After all, [a $5 bearing can protect—or destroy—a $500 pump.] This blog explores the critical role of bearings in electric pumps, why quality matters, and how to make informed decisions when purchasing and maintaining pumps.

What Bearings Do Inside a Pump

Bearings might not be the most visible pump component, but they are indispensable for functionality. Here's what they do:

· Support the Rotating Shaft: Bearings provide the physical support needed for the shaft's rotational movement within tight tolerances.

· Maintain Alignment: They prevent misalignment, which could lead to friction, wear, and mechanical failure.

· Reduce Friction: Low-quality bearings can generate excessive friction, wasting energy and generating heat that degrades the pump motor.

· Absorb Radial and Axial Loads: Bearings manage the forces acting on the shaft, including both radial loads (perpendicular to the shaft) and axial loads (along the shaft's length).

Without high-quality bearings, even the most advanced electric pump will experience performance issues, leading to inefficiency and breakdowns.

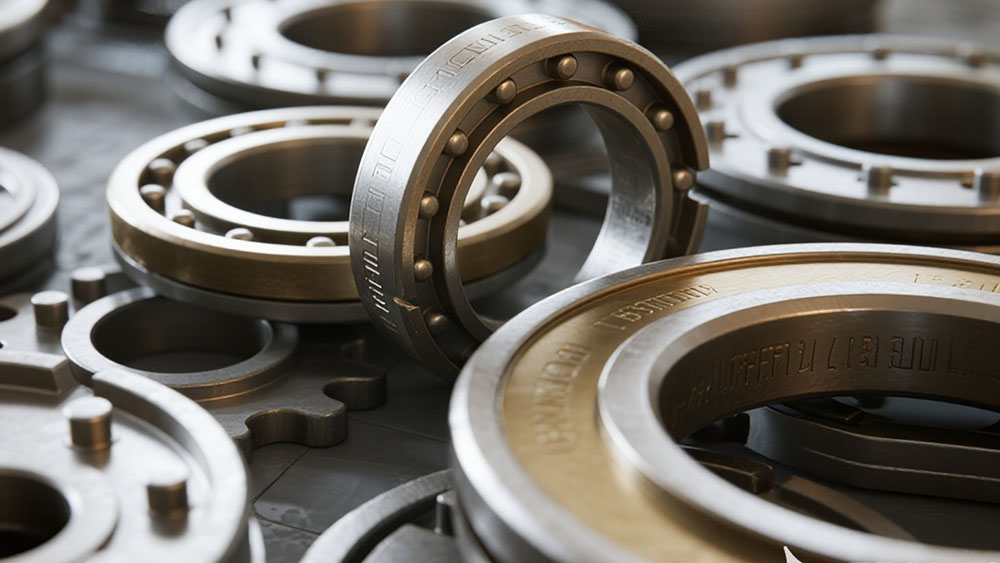

Types of Bearings Commonly Used in Pumps

Different kinds of pumps require bearings tailored to their specific operational needs. The most common types include:

1. Ball Bearings: Well-suited for light to moderate loads, these bearings are often used in smaller electric pumps.

2. Roller Bearings: Designed for handling heavier radial loads, they are preferred for industrial applications.

3. Sleeve (Journal) Bearings: These are simpler in construction and work well for large, low-speed pump shafts.

4. Deep Groove Bearings: Ideal for small electric pumps, they accommodate both radial and axial loads while maintaining low noise and vibration levels.

Materials and Construction

The materials and design of bearings significantly impact their performance. Here are the construction details that matter:

Stainless Steel vs. Ceramic vs. Plastic: Stainless steel provides robustness and corrosion resistance, while ceramic bearings offer low friction and high durability. Plastic bearings, though lightweight, are generally limited to specific, low-stress environments.

Importance of Seals and Lubrication: Sealed bearings protect against contaminants, while proper lubrication reduces friction and heat, prolonging bearing life.

Choosing the right bearing isn't just a technical decision; it's a strategic investment. Here's how bearing quality directly impacts pump operations.

The Risks of Poor-Quality Bearings

Substandard bearings can lead to a cascade of operational problems:

Increased Vibration: Poor-quality bearings don’t provide the stability required, leading to excessive vibration that can damage the motor and components.

Higher Noise Levels: Deteriorated bearings generate louder operational noise, which may indicate imminent failure.

Overheating and Motor Wear: Subpar bearings increase friction, leading to overheating that compromises motor integrity.

Premature Pump Failure: Ultimately, poor bearings reduce service life, leading to expensive repairs or replacements.

For procurement teams, these risks translate to hidden costs, including warranty claims, frequent service calls, and customer dissatisfaction. These issues can erode margins and damage reputations over time.

Investing in high-quality bearings yields measurable benefits for performance and reliability.

Improved Efficiency

High-grade bearings reduce friction, meaning less energy is wasted. This also leads to lower operating temperatures, which extends the overall lifespan of the pump.

Extended Lifespan

Premium bearings deliver consistent performance over longer intervals. Fewer sudden breakdowns reduce the total cost of ownership, allowing maintenance teams to focus on proactive care rather than reactive repairs.

Greater Load Handling

High-quality bearings are engineered to handle greater loads without wearing out. This ensures stable and efficient performance even in demanding applications like irrigation, construction, and wastewater management.

Selecting the right bearings involves more than matching technical specifications. Here’s how procurement teams can ensure smarter decisions.

Match Bearing Type to Application

Consider the operating environment and function when selecting bearings:

Clean Water Pumps: Standard corrosion-resistant materials are often sufficient.

Slurry Pumps: Abrasive materials require robust bearings capable of withstanding high wear.

High-Speed vs. High-Load Environments: High-speed pumps demand low-friction bearings, while high-load applications need bearings with reinforced load capacity.

Check Key Specs

Evaluate bearing options based on critical performance metrics:

Load Capacity: Ensure the bearing can manage expected radial and axial forces.

Speed Rating: Match the bearing's speed tolerance to the pump's operating RPMs.

Temperature Tolerance: Select materials that can withstand the pump's thermal environment.

Material Compatibility: For pumps handling chemicals, ensure the bearing materials resist corrosion.

Don't Ignore the Manufacturer

Finally, the origin of the bearing matters:

Industry Leaders: Look for pumps that use bearings from trusted suppliers like NSK, SKF, or NTN.

OEM Compliance: Ask suppliers about bearing specifications when purchasing OEM or private-label pumps.

To maximize bearing performance and lifespan, follow these maintenance best practices:

1. Regular Lubrication Schedules: Use manufacturer-recommended lubricants to minimize friction.

2. Monitor Noise and Vibration: Abnormal sounds or vibrations are early indicators of bearing wear.

3. Bearing Temperature Checks: Regularly monitor bearing temperatures to detect overheating before failures occur.

4. Know the Signs of Replacement: Replace bearings when they show cracks, deformation, or a loss of smooth rotation.

By integrating these maintenance practices, service teams can prevent unplanned downtime and extend the operational life of electric pumps.

Consider this example from the field:

A municipal drainage project was delayed for three weeks because of a failed bearing in a submersible pump. The faulty bearing, which cost a mere fraction of the pump, led to considerable downtime, labor costs, and a missed project deadline. This illustrates the cascading consequences of skimping on bearing quality.

Bearings play a pivotal role in ensuring the smooth operation, efficiency, and longevity of electric pumps. For pump procurement specialists, distributors, and service teams, recognizing and prioritizing bearing quality is crucial to avoiding costly downtime and maintaining customer satisfaction. Poor-quality bearings might reduce the upfront cost but will lead to exponentially higher expenses in service disruptions and replacements.

The next time you're sourcing electric pumps or maintaining them in the field, ask yourself one critical question: What's inside the motor?

Looking for electric pumps built to last? Ensure bearing quality is a priority for reliable and efficient performance.

Address

No.17 XeDa Jimei Ind. Park, Xiqing Economic Development Area, Tianjin, China

Telephone

+86 13816508465

QUICK LINKS