+86 13816508465

Pump Knowledge

Jul. 21, 2025

The performance, efficiency, and longevity of industrial water pumps hinge on the manufacturing processes that produce them. While the final product may appear straightforward, it results from precise, detailed steps that ensure optimal performance under varying conditions. This article will expand on ten critical manufacturing stages, revealing the technical depth and their profound impact on pump performance.

Choosing the right materials directly influences the pump's resistance to corrosion, durability, and operational lifespan. For example:

Corrosion Resistance: Materials like stainless steel or duplex alloys provide superior protection in aggressive environments, such as chemical or saltwater applications.

Durability: Cast iron, widely used due to its cost-effectiveness and strength, is suitable for freshwater systems, while more advanced alloys are chosen for abrasive or high-pressure operations.

Stringent quality control ensures raw materials meet specific standards through inspections like non-destructive testing (NDT), tensile strength tests, and spectrographic analysis. This stage plays a foundational role in creating reliable, high-performing pumps that withstand strenuous operational demands.

The pump casing and impeller are crafted through advanced casting or molding processes, forming their essential structural shapes. Precision in this process minimizes potential flaws such as porosity, cracking, or misaligned geometries, which could impair fluid flow.

Techniques like investment casting ensure dimensional accuracy, offering smoother internal surfaces, which reduce turbulence and enhance hydraulic efficiency. This attention to detail directly impacts energy efficiency—it reduces friction losses and supports consistent operation, even under high workloads.

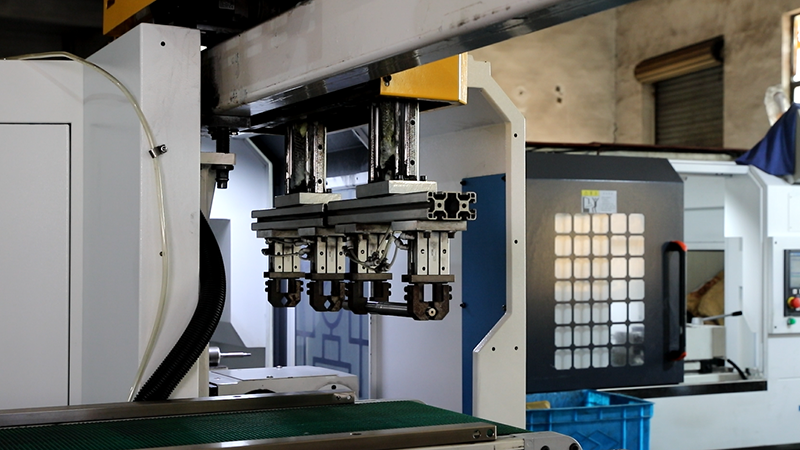

After casting, components undergo machining to achieve precise dimensions. This step involves using CNC (Computer Numerical Control) machines to handle tolerances often within microns. For water pumps, even the smallest misalignment can cause significant issues, such as:

Hydraulic Loss: Erratic fluid flow caused by improperly aligned impellers.

Operational Noise: Poor fitting of mating components increases vibration and resonance.

Multi-axis machining and lapping processes create flawless mating surfaces, ensuring reduced mechanical stress and smooth integration of parts like shafts and impellers.

Surface treatments are a vital defense against environmental degradation, especially for pumps operating in chemically active, abrasive, or high-moisture environments. Common processes include:

Electroplating: Adds a corrosion-resistant layer, commonly used for pumps exposed to saline water.

Powder Coating: Provides robust surface protection that resists scratches while enhancing aesthetics.

Ceramic Coating: Ideal for impellers and volutes, offering superior abrasion resistance.

Surface treatments extend the pump's lifespan significantly, reducing maintenance needs and operational downtime. Selecting the correct treatment based on the pump's probable exposure ensures efficient and lasting performance.

The impeller is essentially the heart of pump operation, responsible for converting mechanical energy into fluid movement. Dynamic balancing ensures the impeller maintains an even weight distribution during rotation, which is critical to achieving:

Operational Stability: Reducing vibration enhances precision and prevents wear to connected components like bearings.

Efficiency: Eliminates energy losses caused by wobbling during high-speed operation.

Testing equipment, such as laser and computer-aided balancing machines, detects even the slightest deviation, guaranteeing the impeller performs optimally in challenging environments.

During assembly, correct shaft alignment is essential to maintain effective pump operation. Misaligned shafts create problems, such as uneven bearing wear and mechanical seal failures. The consequences can lead to reduced efficiency, unplanned shutdowns, and repetitive maintenance cycles.

Laser-guided alignment tools are often used to ensure perfect balance during assembly. Combined with rigorous quality controls, these practices greatly minimize the risk of operational disruptions, allowing consistent performance across various applications.

Seals prevent leaks, ensuring the internal pressure required for efficient pump operation is maintained. Mechanical seals and packing seals are commonly tailored with specialized materials, like carbon or elastomers, to match specific usage conditions. For example:

Mechanical Seals: Withstand high pressures and temperatures, making them ideal for industrial pumps.

Packing Seals: Used for less demanding applications, offering cost-efficiency while ensuring functional reliability.

Post-manufacturing testing replicates real-world pressures and thermal conditions to verify each seal's ability to maintain integrity. This step enhances performance and guarantees long-term operational safety.

For motorized pumps, the integration of motors with pump assemblies defines critical performance metrics such as efficiency, noise, and energy consumption. Quality considerations include:

Motor Winding: High-grade copper and precise winding patterns ensure consistent electrical efficiency.

Insulation Testing: Verifies that motors can handle high voltages without energy leakage.

Correct mounting of the motor—using tools like micrometers to align its casing with pump housings—reduces vibrations, prolongs equipment life, and enhances overall system reliability.

Manufacturers perform stringent quality control to identify defects and ensure the pump meets performance expectations. Among the tests conducted are:

Hydraulic Testing: Verifies flow rate, head, and efficiency to meet designated operational parameters.

Vibration Testing: Measures mechanical stability and identifies misaligned or imbalanced components.

Noise Monitoring: Confirms the pump meets user standards for noise levels.

These tests often follow frameworks like ISO 9001, making it easier to maintain consistency. Through systematic evaluations, manufacturers can rectify issues before the pump reaches the customer, guaranteeing long-term reliability.

The final stage ensures pumps arrive at their destination without damage. Protective measures include:

Shock Absorbers: Minimize mechanical strain during transportation.

Anti-Corrosion Films: Shield exposed surfaces from environmental factors like humidity.

By selecting the right packaging materials and techniques, manufacturers maintain the integrity of pumps during shipping, ensuring that customers receive the product in optimal working condition.

Every step in the manufacturing process contributes to shaping a pump’s performance, efficiency, and reliability. From the material chosen at the beginning to the packaging at the end, precision and expertise are what ultimately result in high-quality, durable water pumps. By understanding and perfecting each of these stages, the industry continues to meet the evolving demands of complex applications.

Address

No.17 XeDa Jimei Ind. Park, Xiqing Economic Development Area, Tianjin, China

Telephone

+86 13816508465

QUICK LINKS