+86 13816508465

Nov. 30, 2023

A submersible grinder pump is a type of sewage pump that is designed to handle wastewater containing solid particles such as sewage, food waste, and other debris that could clog convectional pumps.

The pump is typically installed in a pit or basin and is designed to be submerged in the wastewater. Due to their harsh operating environment, they need to be featured as corrosion resistance, wear resistance and long service life. The more powerful the pump, the greater its force.

In this article, we will provide a brief overview of grinder pumps, covering their working principles and applications, selection criteria, common causes of burnout, and maintenance suggestions.

Working Principle

A submersible grinder pump is equipped with a grinding mechanism that breaks down solid waste materials into smaller pieces that can be easily transported through the pump system. When wastewater enters the pump, it first passes through a grinder mechanism that grinds the solid waste into smaller particles. The ground waste is then transported through the pump impeller, which uses centrifugal force to move the wastewater through the system.

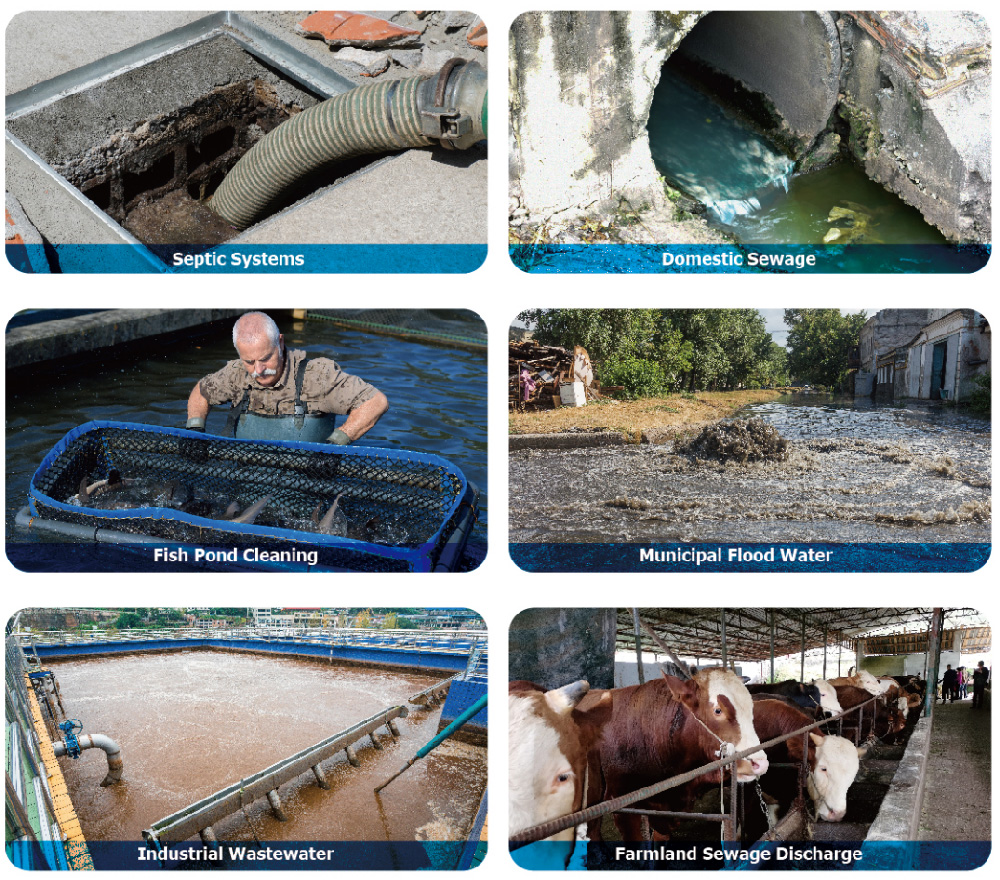

Applications

The submersible grinder pump is typically used in wastewater treatment applications, such as residential and commercial sewage systems, as well as in industrial processes where wastewater contains solid particles. Its ability to handle solid waste makes it an ideal choice for applications where conventional pumps would be ineffective or prone to clogging.

Grinding Mechanism

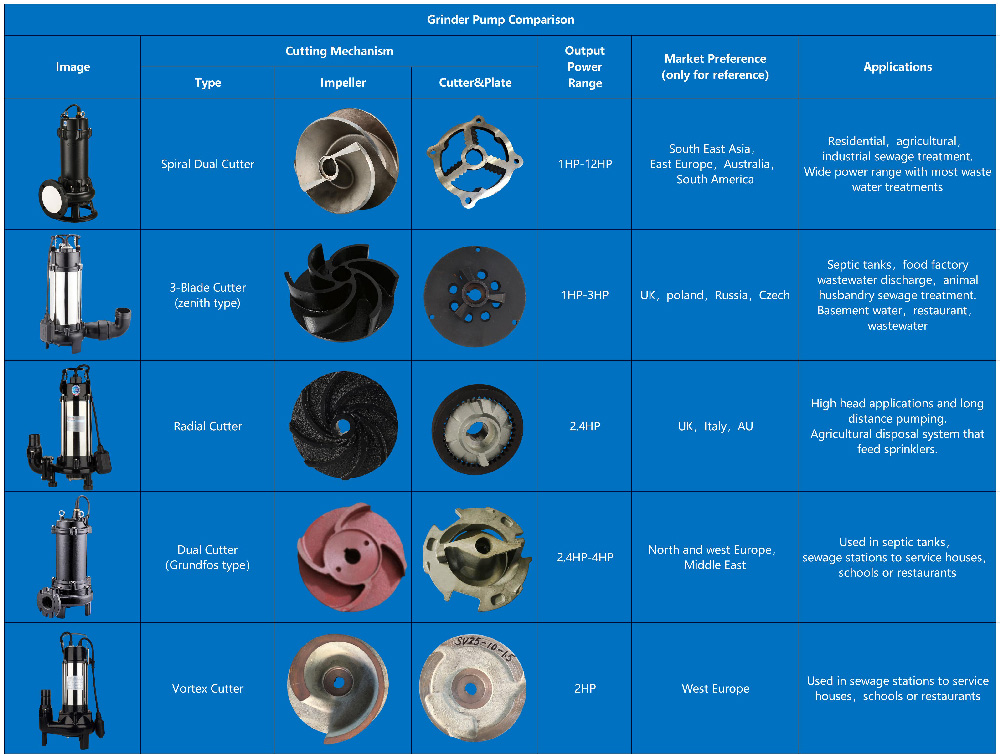

There are various types of grinder pumps with different grinding structure. When choosing a grinder pump for your business, it is important to consider the specific application and the type of waste that will be encountered.

Here is a list of sewage grinder pumps from our company which covers the general types in the market and can be referred before you choose one.

Selection Criteria

When selecting a grinder pump, the grinding mechanism is only one part to consider. We must also pay attention to the materials and design, capacity and energy consumption to ensure that the pump operate in a sealed, corrosion-resistant, and long-term stable manner.

Materials and Design

Compared to conventional pumps, the material of the grinder pump and the design of the mechanical seal must be strong enough to avoid shutdown caused by wear or corrosion of debris in the sewage.

Pump material

Conventional domestic sewage is neutral or weakly alkaline. Gray cast iron material is chosen because of its outstanding rust resistance, and its anti-wear and thermal conductivity performance should not be underestimated. Gray cast iron is currently the material of choice for most motors and pump casings.

While anti-corrosion is a priority to consider in some applications, stainless steel pump casing is preferred. But they are mostly seen in residential systems and costs higher.

Seal design

Choosing a double mechanical seal with an independent mechanical seal oil chamber design, can effectively extend the service life of the mechanical seals. At the same time, a layer of skeleton oil seal filters out gravel to protect the mechanical seal.

Considering of harsh working conditions, silicone to silicone seal is more preferred.

Pump shaft material

The pump shaft is commonly made of AISI420 material. To improve corrosion resistance, it can be upgraded to a stainless steel welded shaft, which is more resistant to corrosion and durable.

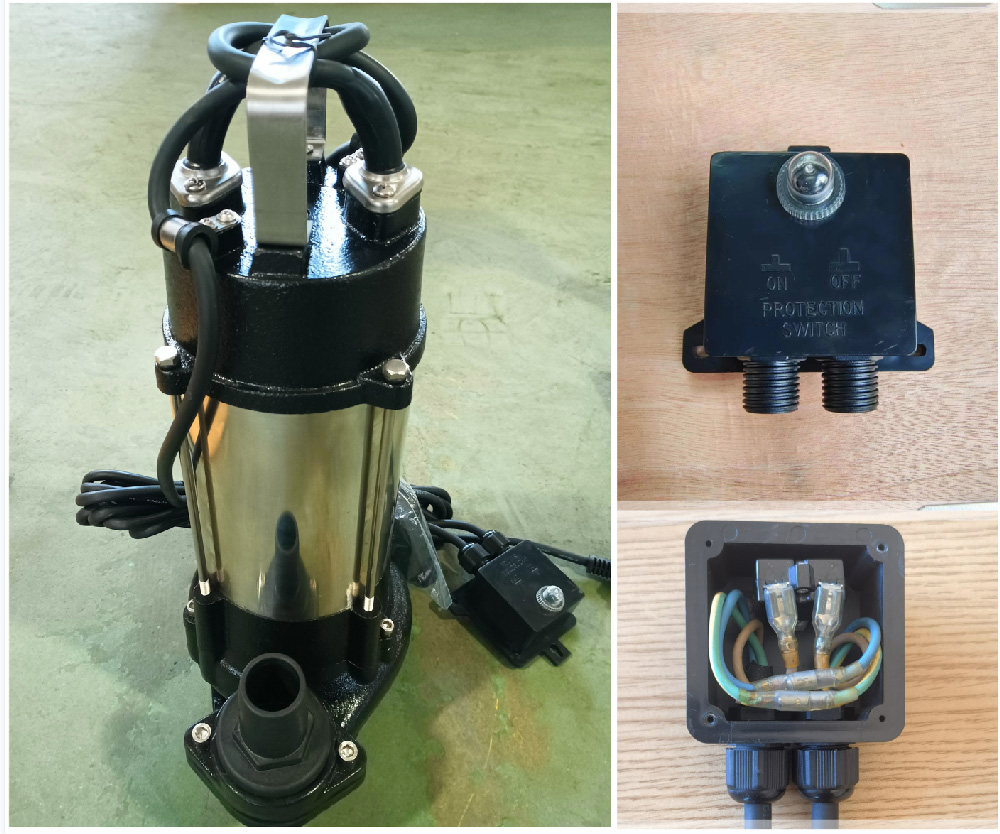

Cable design

Cable design is an important consideration in applications where cables will be exposed to high pressure or harsh environments. In these situations, it is important to choose cables that are designed to withstand the pressures and environmental factors they will be exposed to. Waterproofed cables are a popular choice where water resistance is important. These cables are designed to prevent water from penetrating the cable jacket and reaching the conductors inside. This can help to prevent damage to the cable and ensure reliable operation in wet or humid environments. An integrated rubber cable or epoxy resin cable can be chosen for safety.

Capacity and Energy Consumption

Solid throughput capacity

When selecting the impeller, not only the flow rate and head should be considered, but also the throughput capacity to reduce the possibility of blockage. Sewage pumps usually use semi-open impellers with excellent throughput capability.

Energy efficiency

In recent years, the country's concern about the energy consumption of municipal sewage treatment has been gradually increasing. Therefore, while meeting the needs, the design should also consider the pump efficiency, insulation class, and stability to ensure that the sewage pump can run continuously for a long time without stopping.

Common Causes of Burnout

The main reason for burnout is the motor overheating caused by the pump jamming.

Below are common situations that caused:

1-When the grinding or cutting blade encounters hard materials and breaks, the grinding efficiency decreases. If the user does not replace it in time, the object will entangle the blade, causing the pump to jam and the motor to generate heat. The thermal protection works, repeatedly starting and disconnecting for a long time, causing the enameled wire to age and short-circuit.

2-The selected pump power is too small, and the grinding material is too large, causing the cutting force to weaken and the pump to jam, resulting in motor overheating.

3-The pump is not cleaned and maintained regularly, resulting in the accumulation of debris in the pump chamber, causing the impeller to jam and the motor to overheat.

Suggestions

To ensure the efficient operation of grinder pumps, the following tips should be followed:

1-Regularly clean and maintain the grinding blade and impeller to ensure their grinding efficiency.

2-Choose appropriate power and impeller design according to the specific working environment. Grinder pumps with too small power are not suitable for use in harsh environments. It is recommended to prioritize three-phase motors or higher power (>1.5kW) for handling large items such as gloves, clothing, and textile bags.

3-Choose a grinder pump made of corrosion-resistant materials and with a reliable mechanical seal design.

4-Pay attention to the capacity and energy efficiency of the pump to reduce energy consumption and pump longevity.

5-Regularly check the pump for any signs of overheating or jamming and take corrective measures promptly.

6-Add an external over-current protector if necessary. In case of excessive current during motor blockage, the protector will quickly trip, preventing continued power supply to the pump. Once the fault is cleared, the protector needs to be manually reset before restarting the pump to prevent motor burnout.

Conclusion

When it comes to handling wastewater containing solid particles, submersible grinder pumps are the go-to option for efficient and reliable pumping. In this ultimate guide, we've covered everything you need to know about grinder pumps, from their working principles and applications to selection criteria and maintenance suggestions.

By choosing the right pump for your specific application and following these tips for efficient operation, you can ensure smooth and reliable wastewater pumping while minimizing downtime and maintenance costs.

Address

No.17 XeDa Jimei Ind. Park, Xiqing Economic Development Area, Tianjin, China

Telephone

+86 13816508465

QUICK LINKS