+86 13816508465

Jun. 24, 2025

As cities grow vertically and industrial operations scale up, fire protection systems have become indispensable in modern infrastructure. At the heart of these systems lies the fire pump group — the engine that powers reliable water delivery during critical moments.

If you're a distributor, OEM, or fire system integrator, choosing the right pump type is not just about specs — it's about performance, compliance, reliability, and service continuity.

This guide will walk you through key pump types used in fire pump sets, where and how they fit, and the top factors professionals like you consider when sourcing fire pumps.

Core Pump Types in Fire Systems

1. Vertical Multistage Pump (Inline, Top and Bottom Ported)

Key Features: Multi-impeller design for high head, compact footprint, inline top-bottom connection, direct-coupled motor.

Best For: High-rise buildings, sprinkler stabilization, pressure-boosting circuits.

Why It Works:

Saves space in tight pump rooms

Low noise, high energy efficiency

Ideal for VFD (Variable Frequency Drive) control

2. Horizontal Two-Stage Centrifugal Pump

Key Features: Dual impellers in series, high-pressure capacity, horizontal layout.

Best For: Large commercial complexes, factories, or long-distance water supply.

Why It Works:

Delivers higher head than single-stage pumps

More efficient and compact for medium-duty fire flows

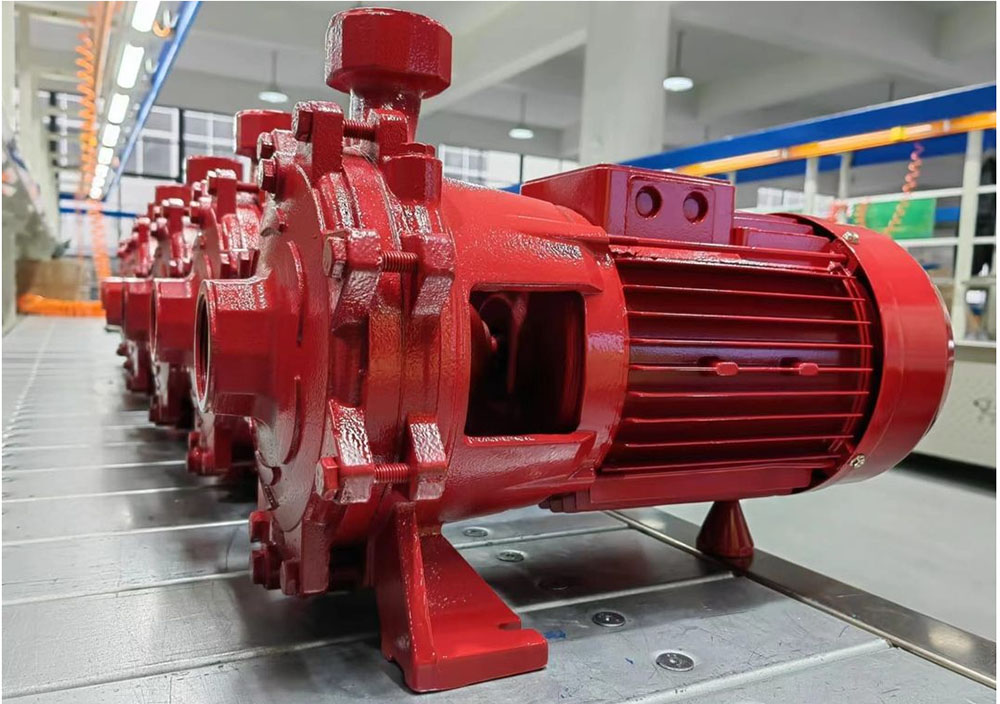

3. End-Suction Centrifugal Pump (Close-Coupled / Split-Coupled)

Key Features: Frontal suction, top discharge, available in close- or split-coupled formats.

Best For: Warehouses, logistics hubs, residential and commercial mid-rise systems.

Why It Works:

Versatile and cost-effective

Diesel or electric compatible

Great for main or standby pump configurations

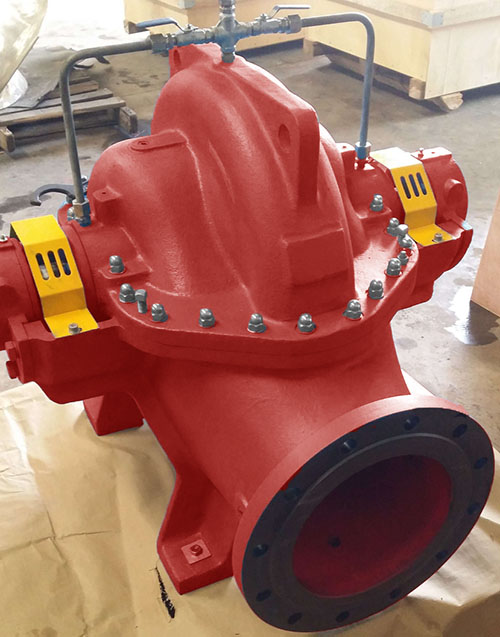

4. Split Case Double Suction Pump

Key Features: Horizontally split casing, double suction impeller for balanced hydraulic loads, heavy-duty construction.

Best For: Airports, municipal fire mains, refineries, large-scale industrial plants.

Why It Works:

Extremely high flow capacity

Easy maintenance with minimal disassembly

Long service life and reliable under continuous operation

What Fire Pump Buyers Care About Most

Fire system integrators and procurement specialists don’t just look at price — they evaluate total system impact. Here are their top decision factors:

1. Performance Curve with Real Test Data

Curves must show real Q-H values, ideally from certified test labs (not marketing estimates).

Tested efficiency points and duty ranges are essential for system matching.

2. Certifications and Compliance

CE, ISO 9001, ISO 14001 are base-level expectations.

NFPA 20, UL/FM approval are preferred or required in projects in Latin America, Middle East, and municipal bidding processes.

If international certs aren't available, independent lab reports (SGS, TUV) are often requested.

3. Construction and Materials

Integrators want peace of mind:

Bronze/stainless steel impellers

Heavy-duty bearings

Double mechanical seals

Corrosion-resistant housings

4. Spare Parts Availability

Common spares (seals, covers, impellers) should be quickly available.

Preventative maintenance kits are a major plus.

5. Range Completeness

Can you supply a full set: main pump + jockey/stabilizer + diesel-driven option + electric cabinet?

One-stop compatibility reduces design and installation errors.

6. Lead Time

Urgent projects may require fast-track delivery.

Some integrators prefer suppliers with the flexibility to deliver partial shipments (e.g., test units first, batch later).

7. Technical Responsiveness

Can you supply CAD drawings? Motor data sheets? Dimensional layouts?

Quick engineering support is key in winning and executing tenders.

Selection Matrix (By Scenario)

Application Area | Recommended Pump Type |

High-rise buildings | Vertical multistage inline |

Industrial plants | Horizontal two-stage / split case |

Large-scale projects | Split case double suction |

Compact pump rooms | Inline or close-coupled end-suction |

Diesel backup systems | Split-coupled end-suction or split case |

How We Support Our Fire Pump Partners

As an experienced manufacturer, we offer:

Full fire pump product line — from compact jockey pumps to high-capacity diesel units

OEM branding, box customization, and multilingual documentation

In-stock spares and responsive technical after-sales

Sizing tools, data sheets, CAD files, and quick quotations

Engineering support for project designers and consultants

Whether you're sourcing a fire pump for a commercial building or a complete firefighting pump set for industrial use, Streampumps offers tested, durable, and cost-effective solutions.

Contact us today for product catalogs, technical packages, or sample quotations.

Address

No.17 XeDa Jimei Ind. Park, Xiqing Economic Development Area, Tianjin, China

Telephone

+86 13816508465

QUICK LINKS